IV–5

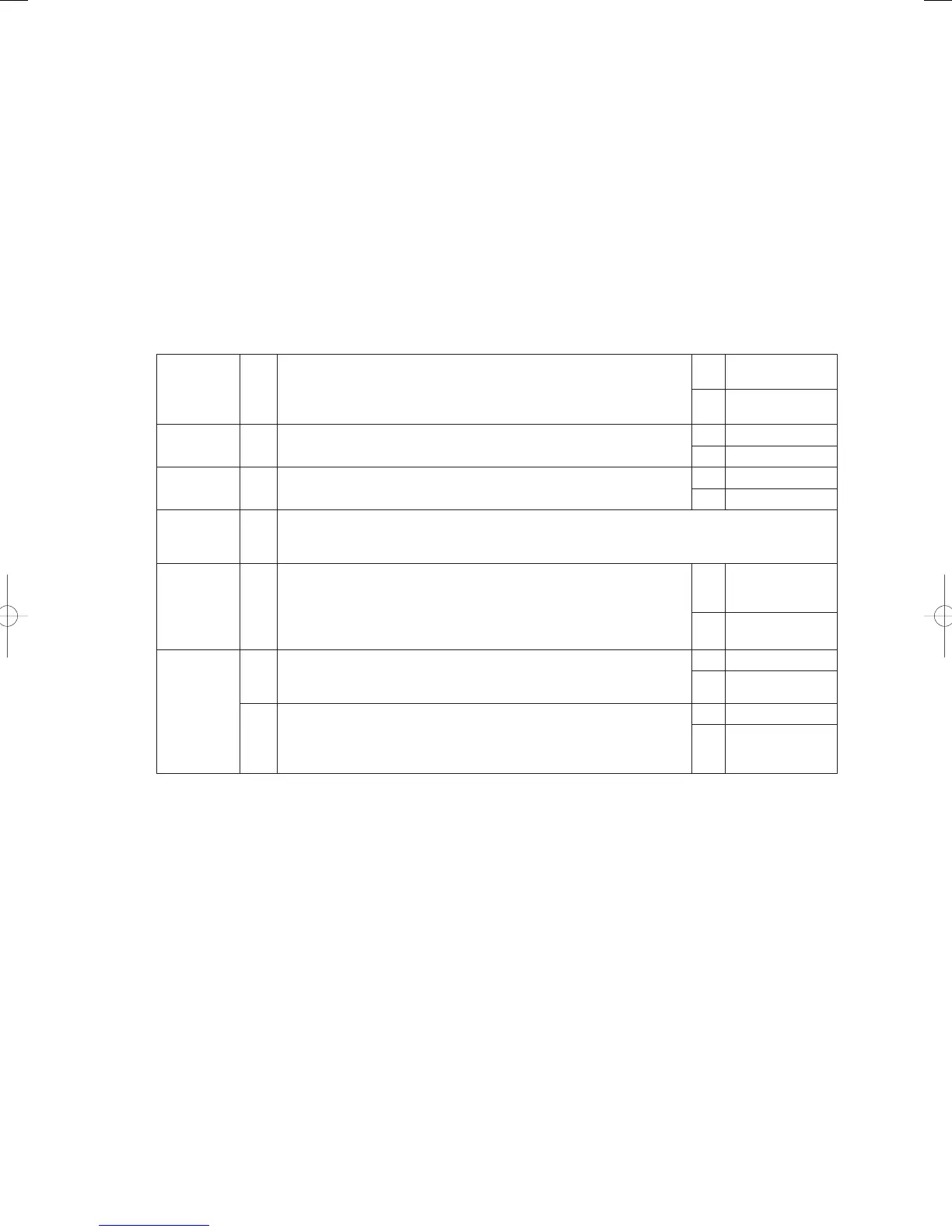

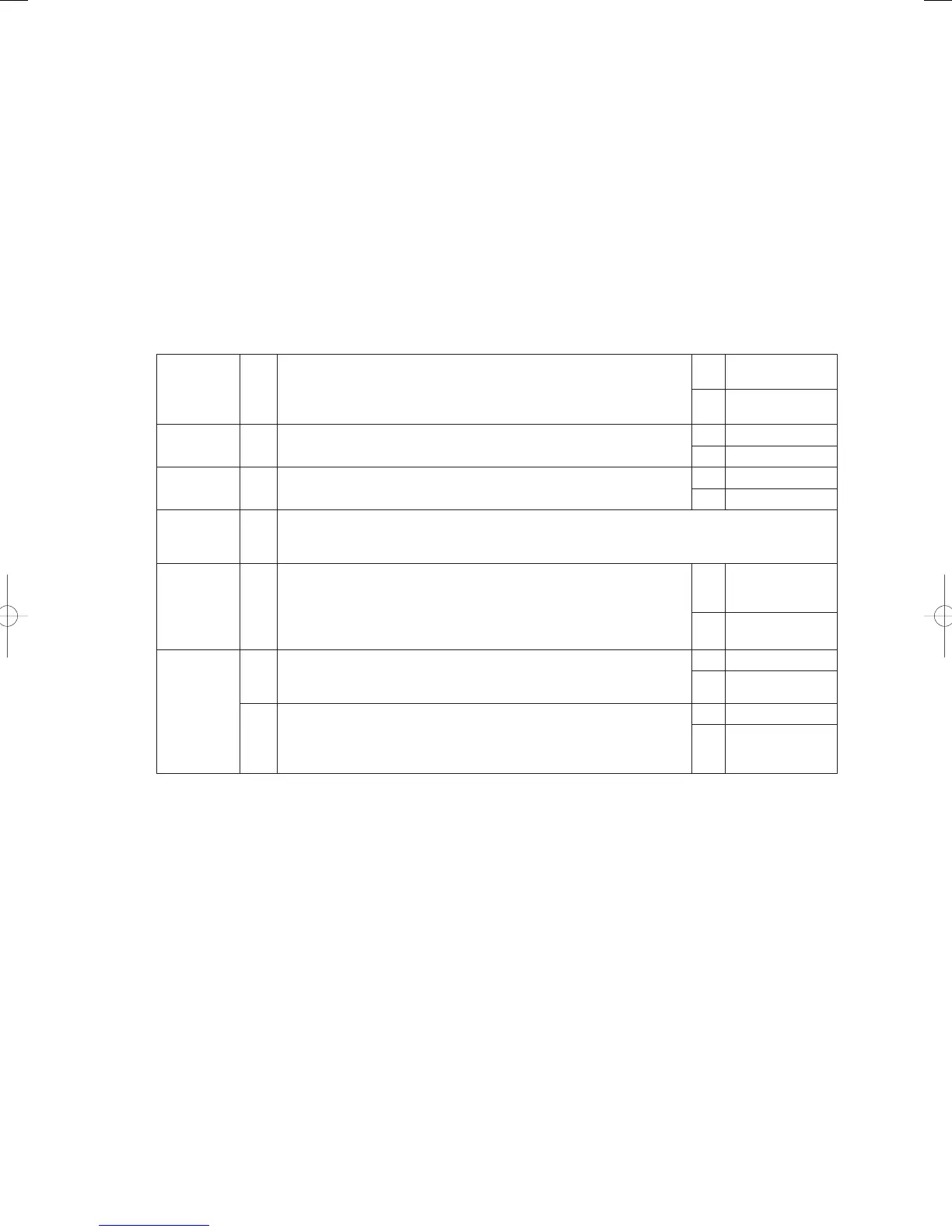

A03 Engine High-Revolution Error

Error detection method

Engine revolution speed is,

45.0 ~ 71.0 kw models

• Engine revolution speed is more than 2,300min

-1

continuously for 30 seconds

• Engine revolution speed is more than 2,400min

-1

continuously for 10 seconds

• Engine revolution speed is more than 2,500min

-1

continuously for 1 second

85.0 kw models

• Engine revolution speed is more than 2,700min

-1

continuously for 30 seconds

• Engine revolution speed is more than 2,800min

-1

continuously for 10 seconds

• Engine revolution speed is more than 2,900min

-1

continuously for 1 second

If any of above conditions occur, the engine stops momentarily and an error fl ag is set. An Engine Speed Too

High trouble is assumed when the error fl ag has stopped the engine 5 consecutive times in 1 hour. ”

Troubleshooting

1

Check

revolution

speed

1-1

Measure actual revolution speed using a revolution meter. Was there

high revolution when the error occurred?

Yes 2-1

No 4-1

2

Mixer

2-1 Is the throttle valve locked or sticking?

Yes Repair

No 3-1

3

Compressor

3-1 Does the compressor have any reason for abnormally low load?

OK 5-1

NG Restore

4

Ignition

pulse

4-1 Ignition coil, cam angle sensor, and crank angle sensor

5

Wiring

5-1

• Any poor connections, poor contact or broken wires between

throttle (step motor) wiring and connector? (Wiring from outdoor

main board connector 6P (black) CN066 to throttle (step motor))

• In the relay part, is the wiring for the throttle (step motor) and fuel

regulating valve crossed?

Yes

Reset the power

after repair wiring

No 6-1

6

Mixer 6-1

Does the throttle (step motor) coil resistance measure about 120Ω?

(Disconnect relay connector 6P-1, and measure between No. 1 (red)

and No. 2/No. 3, and between No. 4 (orange) and No. 5/No. 6.)

Yes 6 -2

No Replace mixer

6-2

Is 4 V DC applied between control board connector 6P (black)

CN066 No. 1 (+) and No. 2 (-)/No. 3 (-) as well as between No.

4 (+) and No. 5 (-)/No. 6 (-) when turning the power ON (during

positioning)?

Yes Replace mixer

No

Replace outdoor

main board

● For work procedure for replacing outdoor main board, see “5. Reference Document”.

● For board and Electrical Wiring Diagram, see Chapter 6.

• Outdoor main board: page VI-2

• Outdoor power board: page VI-3

• Converter board: VI-4

• Indoor control board for DC motor models: page VI-5

• Outdoor Unit Electrical Wiring Diagram: page VI-6

GHPtroubleshooting.indbIV‒5GHPtroubleshooting.indbIV‒5 2012/11/2611:20:052012/11/2611:20:05

Loading...

Loading...