IV–9

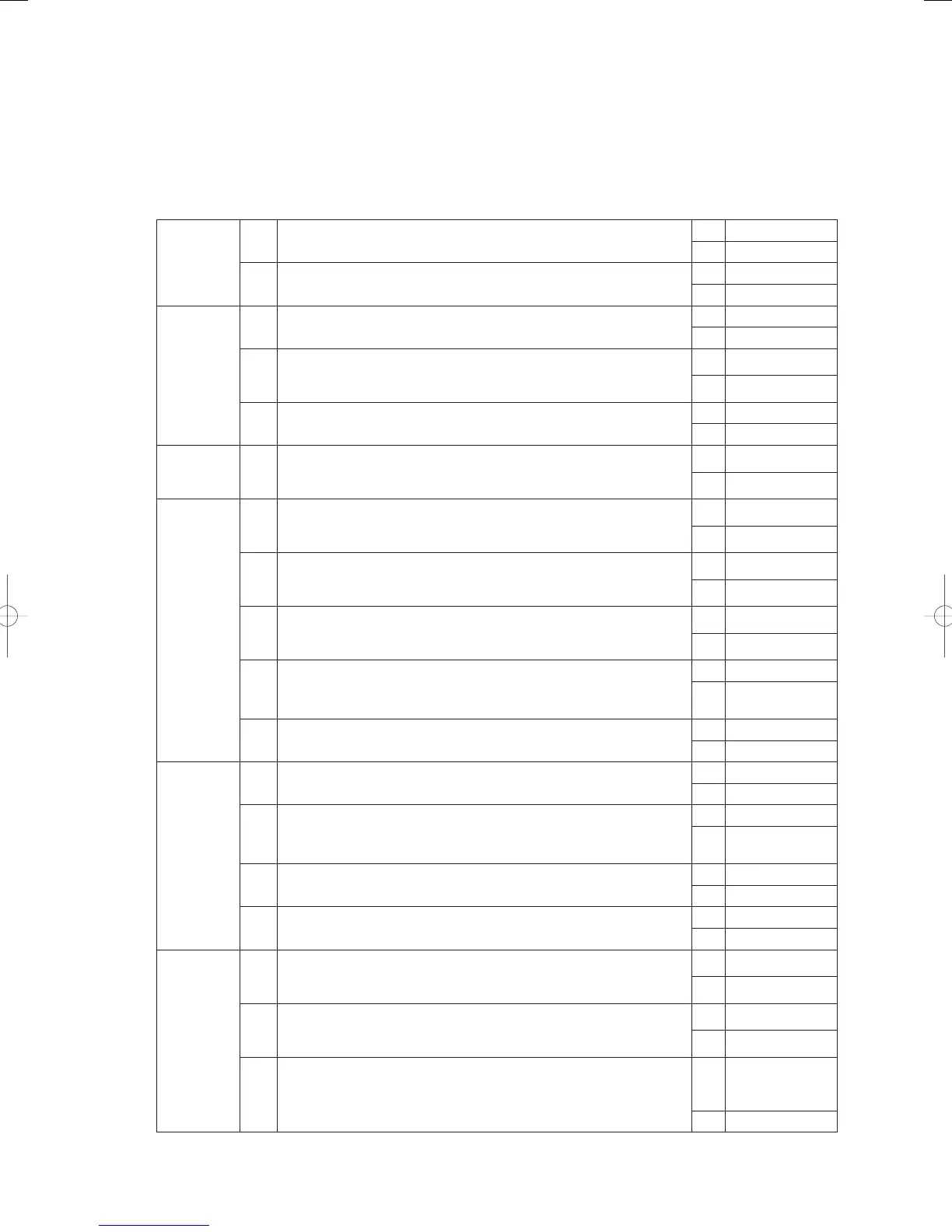

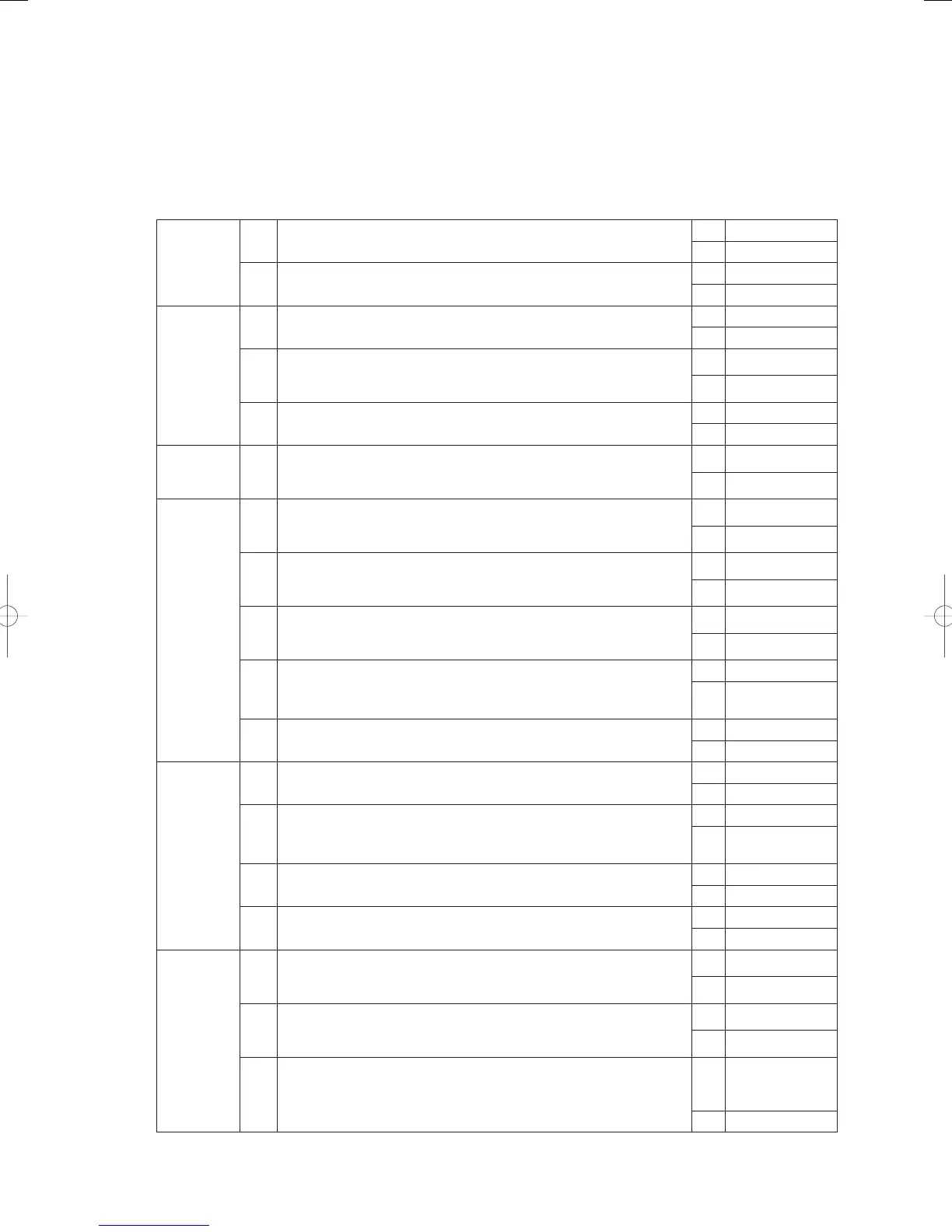

A06 Engine Start Failure

Error detection method

When the engine will not start despite cranking being carried out 30 times (revolution speed detected) during

engine start-up (cranking = 5 seconds ON, 10 seconds OFF.)

* Enforced pauses of 3 minutes every 5 cranks and 10 minutes every 15 cranks are in effect.

Troubleshooting

1

Engine

1-1

Has the fuel gas pressure dropped? Is the fuel empty? Measure the

pressure at the gas pressure measuring port during cranking.

OK 2-1

NG 1-2

1-2

Is the gas solenoid valve SW (S002 on the outdoor unit’s main board)

set at NORM?

Yes 4-1

No Set SW at NORM

2

Plug

2-1

Are spark emissions normal? (Remove plug and check outside. Or,

check with a timing light.)

Yes 3 -1

No 2-2

2-2

Are there any poor connections, poor contacts, poor crimping or

severed wires between the ignition wiring and the outdoor unit’s main

board connector 6P (white) CN010 and 6P (black)/CN011?

Yes Repair Wiring

No 2-3

2-3 Inspect ignition plug.

OK 7-1

NG Replace plug

3

Zero

governor

3-1 Inspect zero governor.

OK 5-1

NG Restore

4

Gas

solenoid

valve/Gas

adjustment

valve

4-1

Is DC180V being applied between the fuel gas solenoid valve relay

connector 4P-1 (white) No. 1 (+) and No. 2 (–) and between No. 3 (+)

and No. 4 (–) during cranking?

Yes 4-2

No 6-1

4-2

Is DC180V or more being applied between the fuel gas solenoid

valve coil terminals during cranking?

(See 4-4 for gas-type C models.)

Yes 4- 4

No 4-3

4-3

Are there any poor wiring connections, crimping or severed wires

between the fuel gas solenoid valve relay connector 4P-1 (white) and

the solenoid valve?

Yes Repair Wiring

No 4-4

4-4

Are fuel gas solenoid valve operations malfunctioning?

(Check for coil breakage, foreign matter, fuel gas passage blockages,

etc.)

OK 4-5

NG

Repair

(or replace)

4-5

Are the throttle (step motor) and fuel gas regulating valves operating

normally?

OK 5-1

NG Replace

5

Engine

5-1 Measure compression.

OK 5-3

NG 5-2

5-2

Check 6-1 again after washing the valve and adjusting the valve

clearance. Any problem with compression?

OK 5-3

NG

Replace engine

head

5-3 Is the air cleaner soiled? (Visual inspection)

OK 5-4

NG Clean/replace

5-4 Has the ignition timing been adjusted?

Yes 6 -1

No Adjust

6

Solenoid

valve wiring/

circuit board

6-1

Is 180V DC being applied between the outdoor unit’s power board

connector 7P (white) CN041 pin 1 (+) and pin 3 (–) and between pin 5

(+) and pin 7 (–) during cranking?

Yes 6 -2

No 6-3

6-2

Are there any poor connections, contacts, crimping or severed wires

between the outdoor unit’s power board connector 7P (white) CN041

and the fuel gas solenoid valve relay connector 4P-1 (white)?

Yes Repair Wiring

No 6-3

6-3

Is 200V AC being applied between the outdoor unit’s power board

connector 3P (white) CN002 No. 1 to No. 3?

Yes

Replace the

outdoor unit’s

power board

No 6-4

GHPtroubleshooting.indbIV‒9GHPtroubleshooting.indbIV‒9 2012/11/2611:20:062012/11/2611:20:06

Loading...

Loading...