IV–82

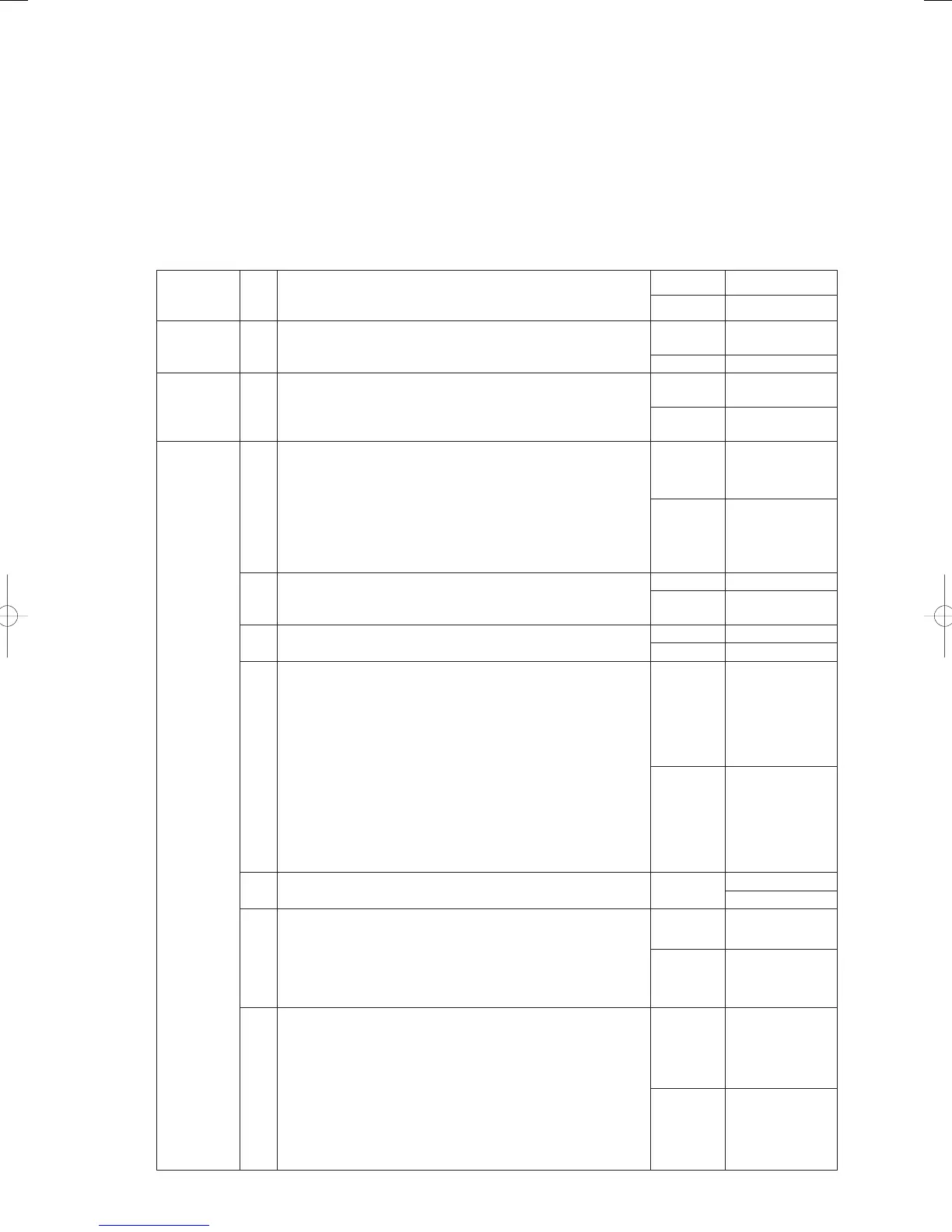

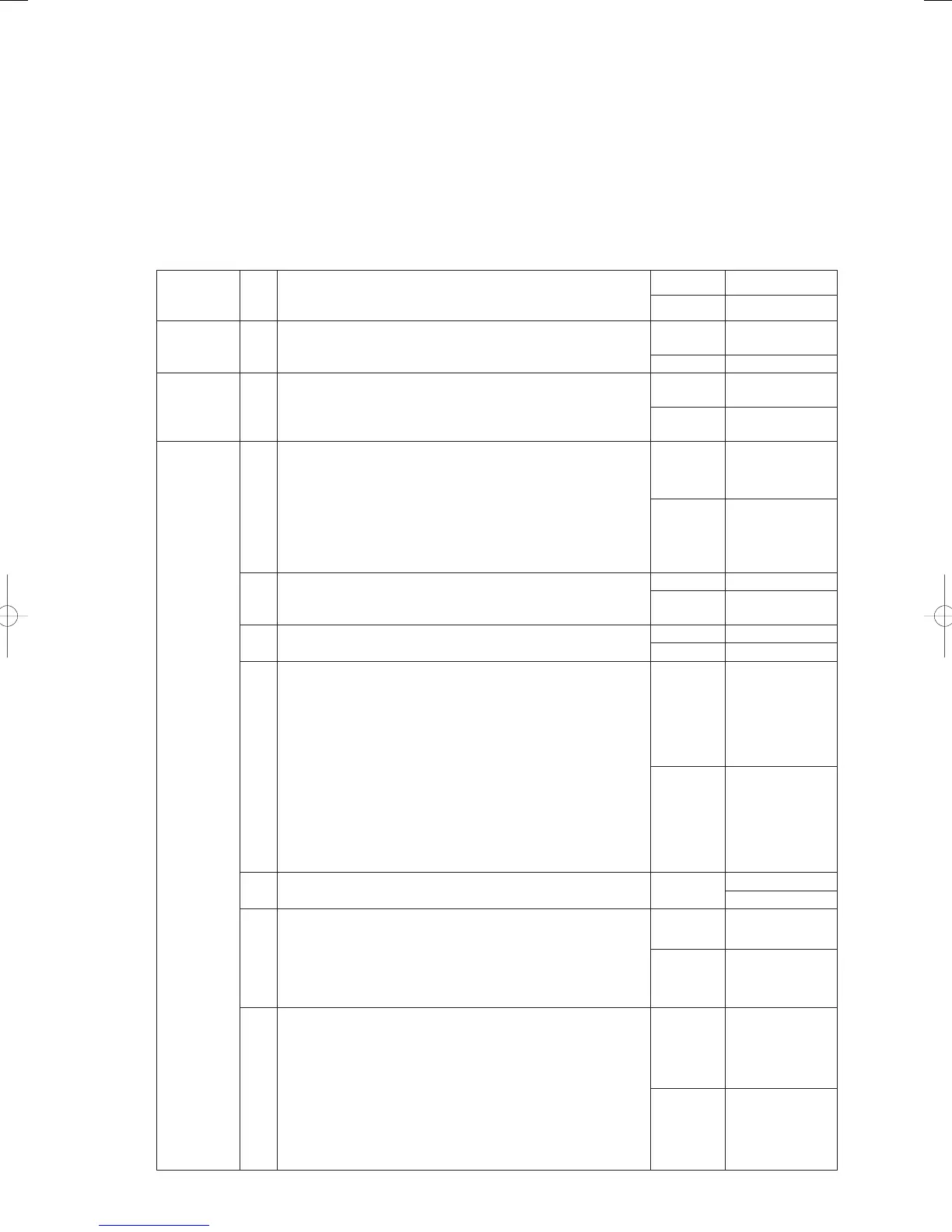

P03 High Compressor Discharge Temperature

Error detection method

• When the compressor discharge temperature ≥ 130°C during engine operation (complete combustion), the

engine is stopped and an error fl ag is set.

A Compressor Discharge Temp. High fault is assumed when this fl ag has shut down the engine 5 consecutive

times.

• Revolution speed setting > minimum revolution speed is not included in pre-trip.

• Not included in pre-trip when liquid valve opening ≤ 400 step.

Troubleshooting

1

Sensor 1-1

Disconnect compressor outlet temperature sensor connector

2P (red) CN054 and measure resistance. Appropriate value?

(See “5. Reference Document” for thermistor characteristics.)

Yes 2-1

No Replace sensor

2

Out of gas

2-1

Out of gas? Determine using compressor outlet pressure,

compressor inlet pressure, and indoor/outdoor electric valve

opening.

Yes

Repair leak and

charge gas.

No 3-1

3

Tubing

3-1

Any symptoms of pump down? Determine with indoor coil

temperature

Yes

Inspect indoor

unit tubing

No

Inspect outdoor

unit tubing

4

Inspect

outdoor

solenoid

valves (For

three-way

device)

4-1

Adjust outdoor solenoid valves. Use trial operation mode

to check that the solenoid valves operate normally in

each operating mode (cooling/heating) and measure

tube temperature around solenoid valves to assess. (For

information on solenoid valve operation in each operating

mode, see the sections Control functions - Operating control

in the “Outdoor unit manual.” Does the solenoid valve operate

normally?

Yes

Replace outdoor

main board

No 4-2

4-2

Adjust the power board.

Does the power board CN013 output the solenoid power

supply voltage (AC 200V)?

Yes 4 - 3

No

Replace power

board

4-3

Any poor connection and broken wires in wiring between the

power board and the relay board?

Yes Repair wir ing

No 4-4

4-4

Adjust the outdoor main board.

In No. 4 test mode when “v_open” (valve open), is there a

drive output voltage (12 V DC) from discharge valves 1-1, 1-2,

discharge valve 2, suction valve 2-1 and 2-2?

(9P (white) CN018)

Discharge valve 1-1, 1-2: between No. 3 - 9 Discharge valve 2:

between No. 4-9

Suction valve 2-1, 2-2: between No. 6 - 9

Does suction valve 1 output a drive voltage (DC 12V) during

cooling operation?

Suction valve 1: between No. 3 - 9

* Note that suction valve 1 closes when powered (the other

valves operate in the opposite way)

Yes 4 - 5

No

Replace outdoor

main board

4-5

Any poor connection and broken wires in wiring between the

outdoor main board and the relay board?

Repair wiring

4-6

4-6

Adjust the relay board.

In No. 4 test mode when “v_open” (valve open), is there an

output voltage (AC 200V) from discharge valves 1-1, 1-2,

discharge valve 2, suction valve 2-1 and 2-2?

Does suction valve 1 output a voltage (AC 200V) during

cooling operation?

Yes 4 -7

No

Replace relay

board

4-7

Adjust the solenoid valve coil.

(Be sure to turn the power off before starting work.)

Disconnect the connectors of discharge valve 1-1, 1-2,

discharge valve 2, suction valve 1, suction valve 2-1 and 2-2

from the relay board and measure the resistance between No.

1 and 3.

Normal value (20°C) discharge valve 1-1, 1-2: 543 ohm

discharge valve 2: 1132 ohm

Suction valve 1: 1197 ohm suction valve 2-1, 2-2: 543 ohm

Is the coil operating normally?

Resistance

is normal

Replace solenoid

valve

Abnormal

resistance

Replace the

solenoid valve

coil

GHPtroubleshooting.indbIV‒82GHPtroubleshooting.indbIV‒82 2012/11/2611:20:132012/11/2611:20:13

Loading...

Loading...