IV–6

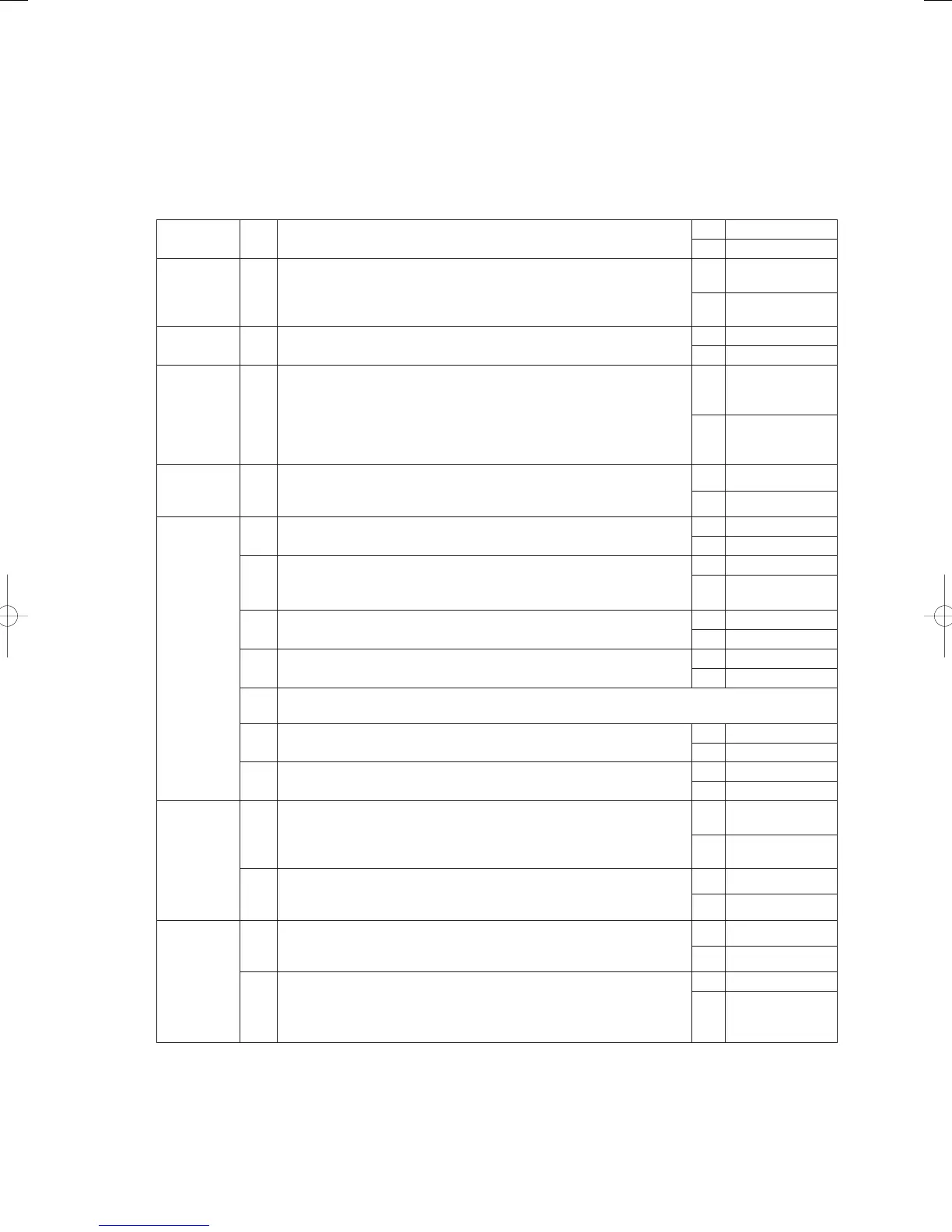

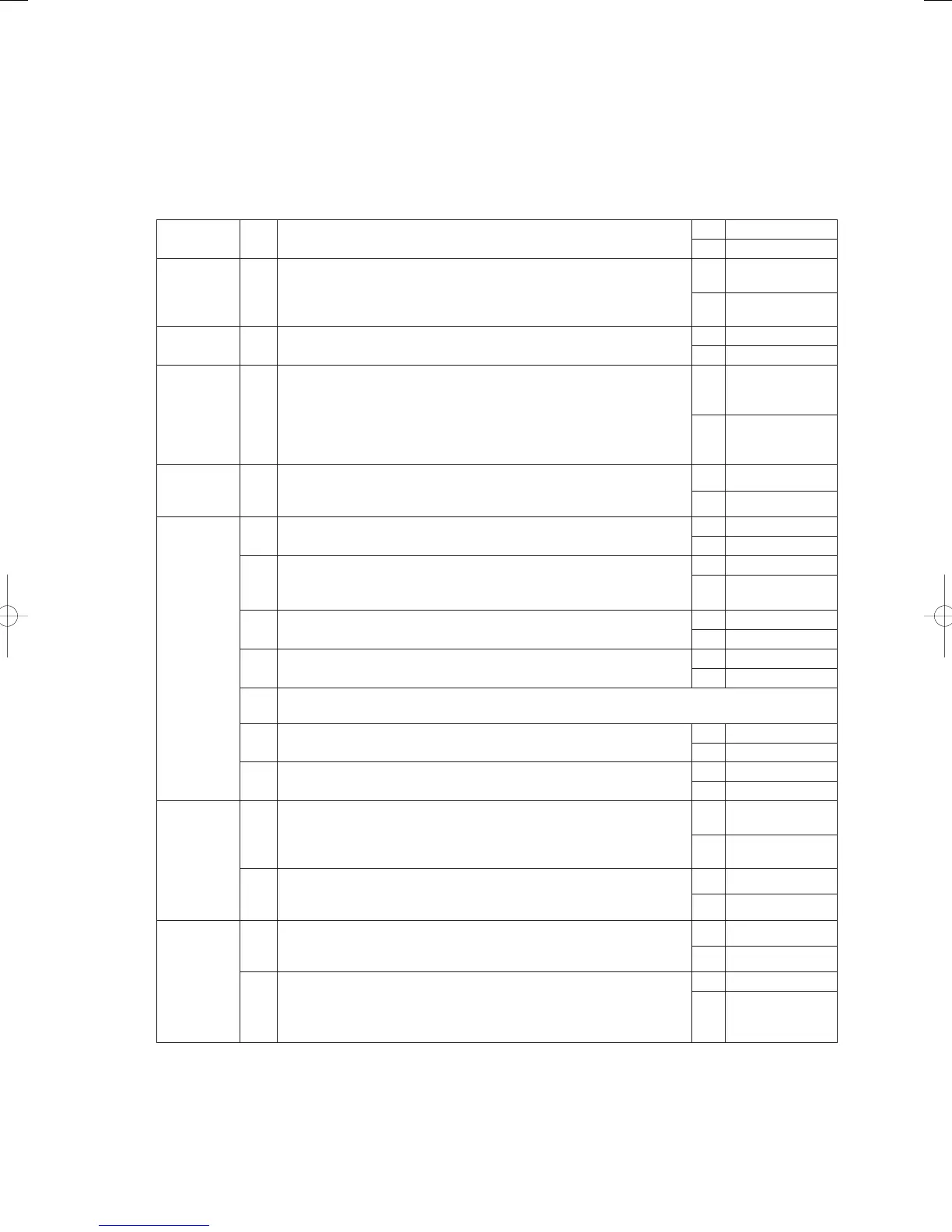

A04 Engine Low-Revolution Error

Error detection method

• When engine revolution speed drops to 700min

-1

or less continuously for 3 seconds during engine operation

(complete combustion), an abnormal fl ag is set and the engine stops. An Engine Speed Too Low condition is

assumed when the error fl ag has stopped the engine 5 consecutive times in 1 hour.

Troubleshooting

1

Fuel

1-1 Has the fuel gas pressure dropped? Is the fuel empty?

OK 2-1

NG Restore

2

Check

revolution

speed

2-1

Measure actual revolution speed using a revolution meter. Are the

revolutions low?

Yes 3 -1

No 4-1

3

Mixer

3-1 Is the throttle valve operating?

Yes 6 -1

No 5-1

4

Ignition

pulse

4-1

Check the ignition coil, cam angle sensor, and crank angle sensor.

Check the ignition coil → Remove the connectors from the ignition

coil one by one during operations. It is normal if changes in

operational status, such as lowered revolutions, occur.

Cam angle & crank angle sensors → Refer to A23 and A24 for

inspections.

OK 5-1

NG Restore

5

Wiring 5-1

Any poor connections, poor contacts or severed wires between the

throttle (step motor) wiring and connector? (Wiring from outdoor main

board connector 6P (black) CN066 to throttle (step motor))

Yes Repair Wiring

No 8-1

6

Engine

6-1 Measure compression (See A06 5-1).

OK 6-3

NG 6-2

6-2

Check 6-1 again after washing the valve and adjusting the valve

clearance. Any problem with compression?

OK 6-3

NG

Replace engine

head

6-3 Are spark emissions normal?

Yes 6 - 6

No 6-4

6-4 Inspect ignition plug (see A06 2-3)

OK 6-5

NG Replace

6-5

Replace the ignition coil, cam angle sensor and crank angle sensor one by one to identify the

defective part.

6-6 Inspect the zero governor (see A06 3-1).

OK 6-7

NG Restore

6-7 Is the ignition timing normal? (see A06 5-4)

OK 7-1

NG Adjust

7

Fuel gas

regulating

valve

7-1

Does the fuel regulating valve (step motor) coil resistance measure

about 120Ω? (Disconnect relay connector 6P-6 and measure

between No. 1 (red) and No. 2/No. 3, and between No. 4 (orange)

and No. 5/No.6.)

OK 7-2

NG Replace mixer

7-2

Is 4V DC being applied between the outdoor main board connector

6P (red) CN065 No. 5 and No. 1/No. 2 as well as between No. 3/No.

4 when the power is on (during positioning)?

Yes Replace mixer

No 8-1

8

Mixer 8-1

Does the throttle (step motor) coil resistance measure about 120Ω?

(Disconnect relay connector 6P-2, and measure between No. 1 (red)

and No. 2/No. 3, and between No. 4 (orange) and No. 5/No. 6.)

Yes 8 -2

No Replace mixer

8-2

Is 4V DC being applied between the outdoor main board connector

6P (black) CN066 No. 1 (+) and No. 2 (-)/No. 3 (-) as well as between

No. 4 (+) and No. 5 (-)/No. 6 (-) when the power is on (during

positioning)?

Yes Replace mixer

No

Replace the

outdoor unit’s

main board

● For work procedure for replacing outdoor main board, see “5. Reference Document”.

● For board and Electrical Wiring Diagram, see Chapter 6.

• Outdoor main board: page VI-2

• Outdoor power board: page VI-3

• Converter board: VI-4

• Indoor control board for DC motor models: page VI-5

• Outdoor Unit Electrical Wiring Diagram: page VI-6

GHPtroubleshooting.indbIV‒6GHPtroubleshooting.indbIV‒6 2012/11/2611:20:062012/11/2611:20:06

Loading...

Loading...