IV–94

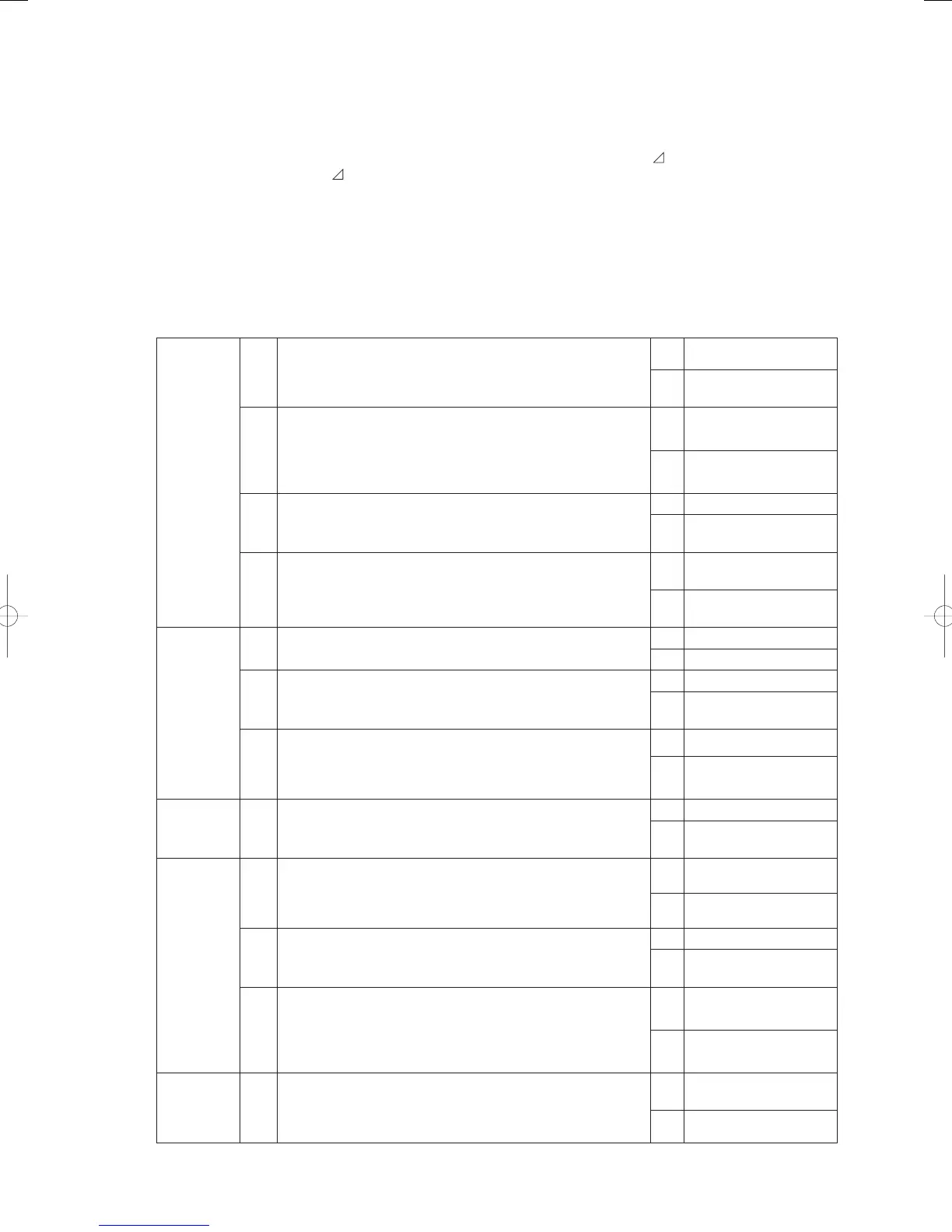

P18 Bypass Valve Error

Error detection method

• A warning is output if it is determined that the outdoor unit needs a bypass valve inspection.

• In practical terms, what happens is that each time there is a small difference ( P ≤ 0.1 MPa) between the

high and low pressure ( P = high pressure - low pressure) 90 seconds after stopping the engine stops, a

suspected error counter increments, and the data is recorded as “pre-trip” warning history data. After the

counter reaches 5, a warning is output on the next complete combustion startup.

Understanding the warning history

The latest P18 data in the warning history is issued immediately after a complete combustion startup. It is not

the data used for detecting the error. If a pre-trip error was detected (when the suspected error counter reaches 5),

that data is the next more recent P18 data.

Troubleshooting

1

Bypass

valve

inspection

1-1

● Bypass valve inspection

During operation, use the No. 4 test mode “v_close” (close

valve) to close the bypass valve (step 0). Check whether

refrigerant is not leaking on entering the bypass.

OK 1-2

NG

Replace the bypass

valve unit

1-2

● Bypass valve inspection

After completing the above inspections, stop the engine and

use No.4 test mode “v_open” (open valve) to open the bypass

to check that the bypass valve operates normally despite the

fl uctuations in tube temperature around the bypass valve.

OK 2-1

NG 1-3

1-3

● Outdoor main board inspection

Is there approximately 12 V of pressure at bypass valve output

ports 5 (+) and 1 to 4 (-) when the power is on?

Yes 1-4

No

Replace outdoor main

board

1-4

● Electric valve coil inspection

Are the resistance values for electric valve connectors 5 and

1 to 4 about 40 Ω?

Yes

Replace the bypass

valve unit

No

Replace the bypass

valve coil

2

Four-way

valve

Inspect

outdoor

solenoid

valves

2-1 Is the outdoor unit a 3-WAY MULTI-device?

Yes 2-3

No 2-2

2-2 Is the four-way valve free from leakage?

OK 3-1

NG

Replace the four-way

valve

2-3

Are the outdoor solenoid valves (discharge valves 1 and 2,

and suction valves 1 and 2) free from leakage?

* Suction valve 1 closes when current fl ows through it (other

solenoid valve remain open)

OK 3-1

NG

Replace the solenoid

valve.

3

Liquid valve

inspection

3-1

● Liquid valve inspection

Any refrigerant leaks past the liquid valve when the liquid

valve is completely closed (step 0)?

OK 4-1

NG

Replace the liquid valve

unit

4

Expansion

valve

inspection

4-1

Is the operation mode heating?

* Note: If you are operating with a 3WAY MULTI, try 4-2 and

4-3 before shutting down the engine as this might be

due to cooling and heating mixed operation.

Yes 4 -2

No 4-3

4-2

● Outdoor expansion valve inspection

Check that there are no refrigerant leaks past the outdoor

expansion valve when the engine is stopped in heating mode.

OK 5-1

NG

Replace the outdoor

expansion valve unit

4-3

● Indoor electric valve inspection

Stop the indoor unit during cooling operation (multiple indoor

unit operation, indoor electric valve opening = 20 steps) and

check to make sure there is no coolant leakage beyond the

indoor electric valve.

OK 5-1

NG

Replace indoor electric

valve unit

5

Pressure

sensor

inspection

5-1

Pressure sensor inspection (refer to the section on F16 for the

inspection procedure)

OK

Replace outdoor main

board

NG Repair

● For work procedure for replacing outdoor main board, see “5. Reference Document”.

GHPtroubleshooting.indbIV‒94GHPtroubleshooting.indbIV‒94 2012/11/2611:20:142012/11/2611:20:14

Loading...

Loading...