IV–66

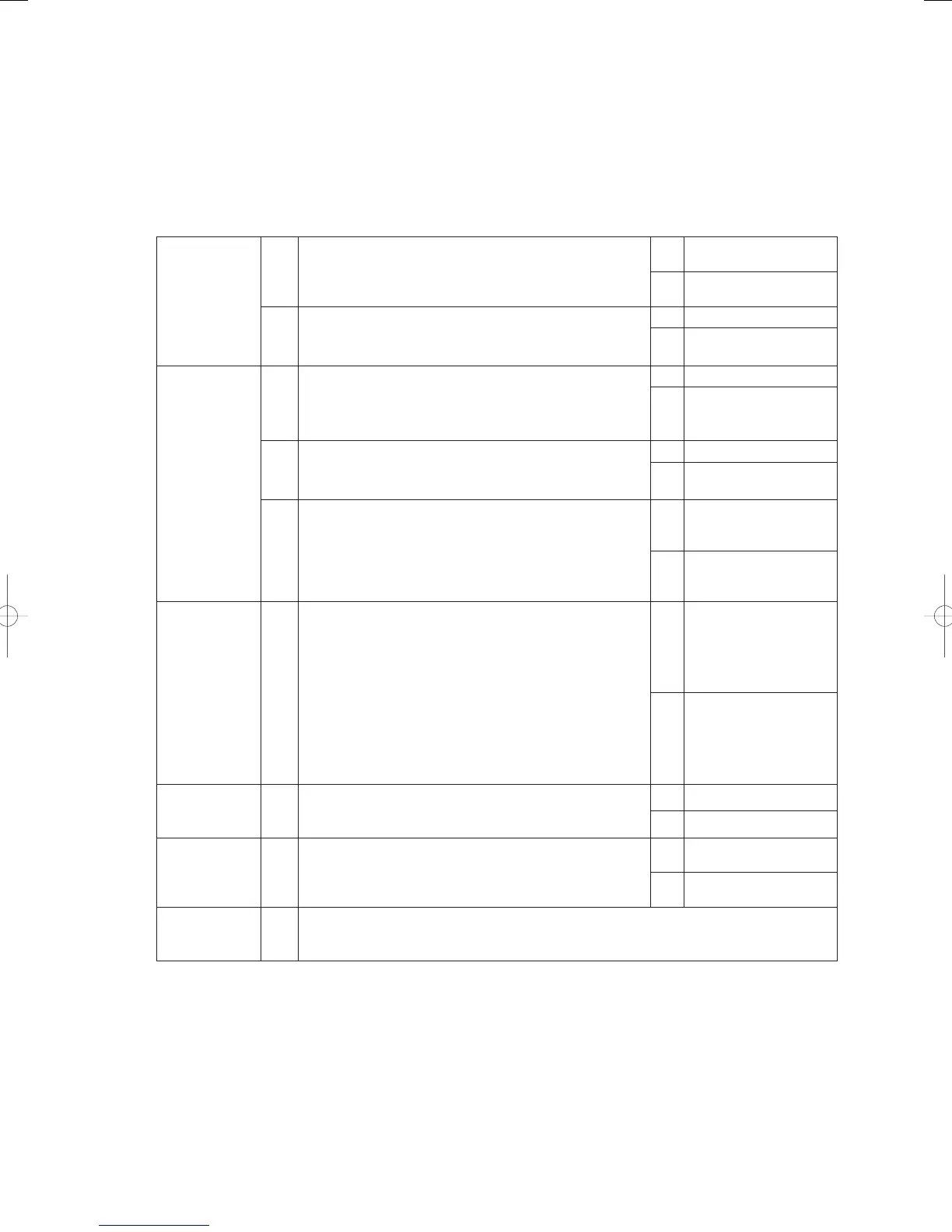

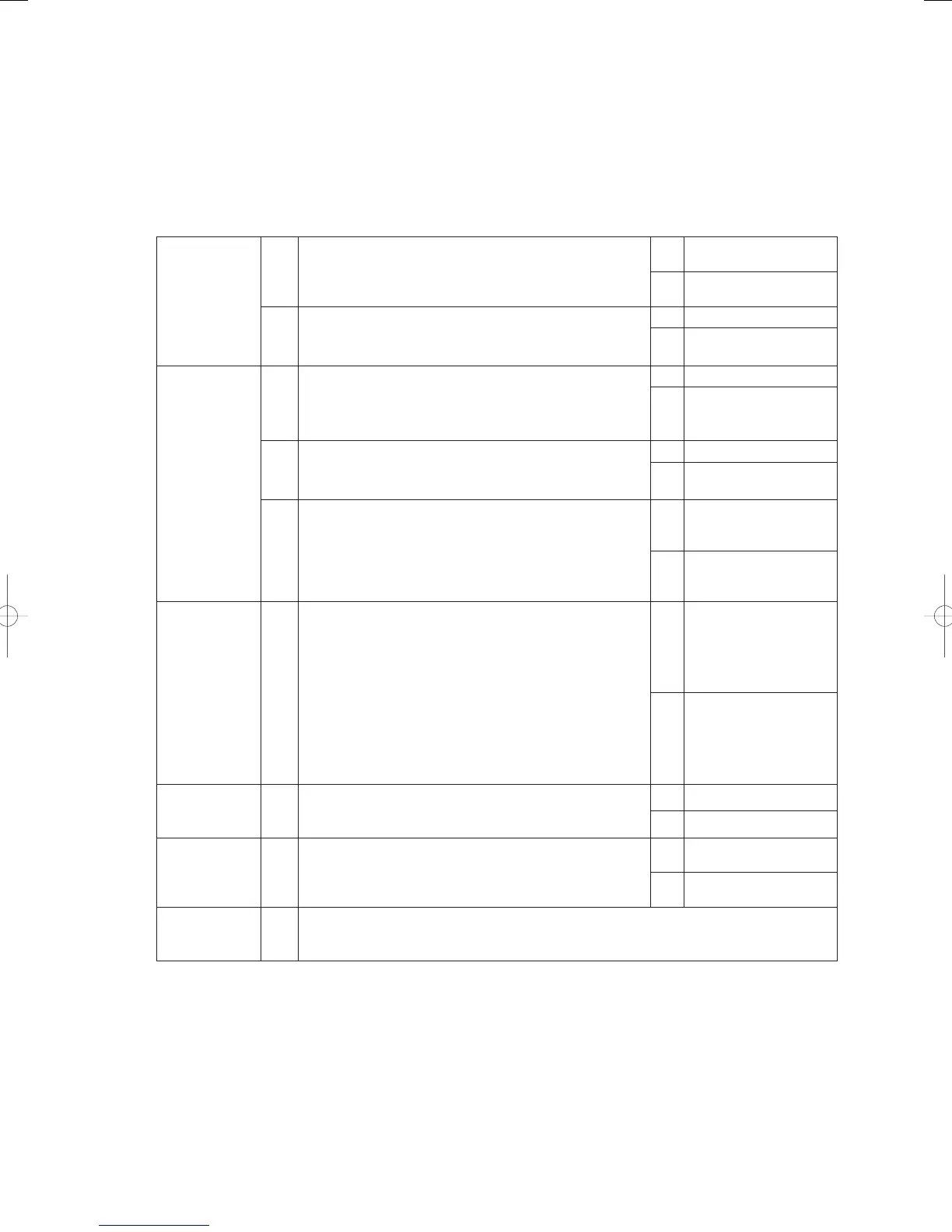

H07 Compressor Oil Depletion Error (for only W MULTI)

Error detection method

Each outdoor unit is inspected for lack of oil and when the oil level is 0 (insuffi cient) for 20 minutes, the engine

stops.

• An H07 failure is assumed when the engine has stopped due to insuffi cient oil a total of 8 times.

• This cumulative count clears when the oil level becomes 1 (normal) or 2 (suffi cient).

Troubleshooting

1

Gas shut-off

valve check

1-1

Is the cooler being operated when the outside temperature

is 5°C or less (or is there any evidence of this)? (If there

is only one outdoor unit, this is “No” regardless of outside

temperature.)

Yes 1-2

No 2-1

1-2 Is the gas shut-off valve (optional) correctly connected?

Yes 2-1

No

Connect the gas shut-off

valve

2

Sensor

2-1

Is the temperature sensor for measuring the oil level

correctly installed? (Must be no disconnected or fl oating

sensors.)

Yes 2-2

No

Resecure the

temperature sensor in

place

2-2

Are the characteristics of the temperature sensor for

measuring the oil level normal? (Temperature sensor:

Check the TH11 resistance value.)

Yes 2-3

No

Replace the temperature

sensor

2-3

Are the measurement results of the temperature sensor

for measuring the oil level valid?

* Compare the No. 26 value displayed on [No.00] on the

outdoor unit’s main board (temperature measurement for

the oil level) with the actual temperature measured with a

thermometer or other tools.

Yes 3 -1

No

Replace the outdoor

unit’s main board

3

Regular oil

return circuit

check

3-1

Operate the outdoor unit and check the temperature of the

regular oil return circuit. Is the temperature rising?

* Check the temperature at the top of the capillary on the

oil return circuit (near the temperature sensor for the oil

level) directly with a thermometer or other tools, or check

the fl uctuations in temperature displayed for the oil level

on the outdoor unit’s main board.

* Although results will differ in accordance with conditions,

the temperature will clearly rise approximately 5 to 10

minutes after the engine has been started up under

normal circumstances.

Yes 4-1

No

Replace the regular oil

return circuit

4

Dry core check 4-1

Is the dry coil blocked?

* Operate the heater and check the temperature

differences at the dry core’s inlet and outlet.

Yes 5 -1

No Replace

5

Suction strainer

check

5-1

Is the suction strainer blocked?

(It is especially important to check this on renewal-

dedicated units.)

Yes 6 -1

No Replace

6

Compressor oil

replenishment

6-1 Replenish 4 L of compressor oil (for the entire system) and keep an eye on the situation.

Note: The solenoid valve coils and the vicinity can become very hot so check operations should be performed

with care.

GHPtroubleshooting.indbIV‒66GHPtroubleshooting.indbIV‒66 2012/11/2611:20:112012/11/2611:20:11

Loading...

Loading...