Parker Hannifin S.p.A Divisione S.B.C. user’s manual TWIN-N and SPD-N

119

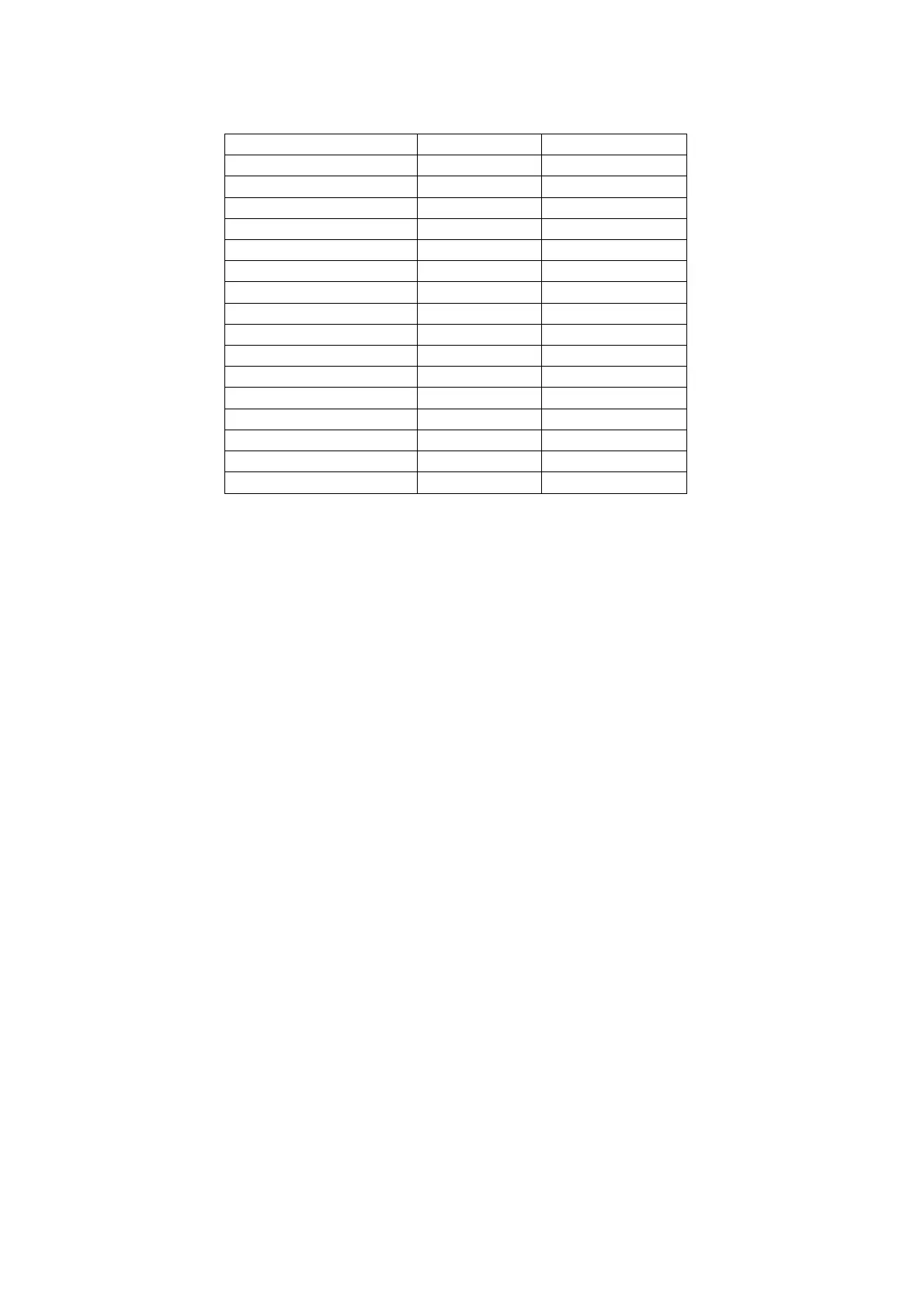

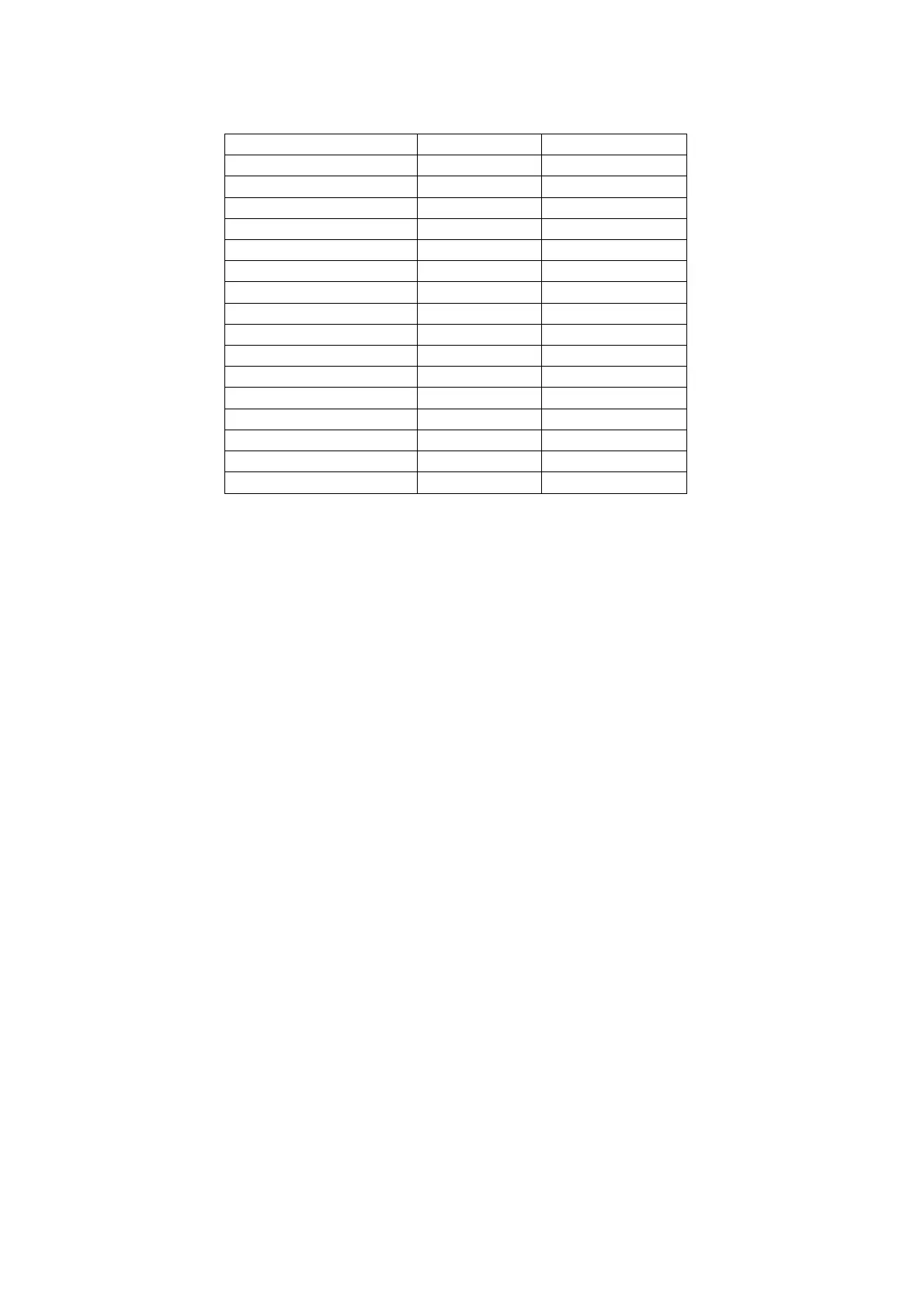

The first 4 bits (b0..b3) of the first byte in each instruction contain the instruction code.

In the first 8 instructions in the table (LD… ORN) and the SET and RES instructions, the

remaining 4 bit of the first byte (b4..b7) contain the value y, while the second byte contains

the value Pa.

In the ADD, SUB, MUL e DIV instructions, the second byte contains the value Pa, the third

byte the value Pb, and the fourth byte the value Pc.

In the END instruction, the second byte is not used.

In the FIN instruction, the fifth bit (b4) of the first byte selects the parameter: b4=0 if it refers

to Pb40, b4=1 if it refers to Pb150; the sixth bit (b5) of the first byte is used for logical

negation: b5=0 the bit is copied, b5=1 the bit is negated before being copied. The second byte

of the FIN instruction contains the value of y.

If the FIN instructions are used, they must be the first instructions of the program and cannot

be more than 2. They occupy the addressed from 0h to 3h. If a FIN instruction is inserted

beginning at the 4h address or after any other instruction, the FIN instruction does not

function and is ignored (NOP).

The instructions must follow each other beginning at address 0h and no byte can be left

empty.

There is only one program and it is terminated with the END instruction.

Examples of using the serial line

In order to better understand how to implement the communication protocol on the serial line,

some examples of each type of message are given below.

The values indicated are only indicative as examples.

First example: reading a 1 byte parameter

Suppose we want to read the value of the parameter Pr25 (release software) and that its value

is 43. Suppose also that the converter has the serial address 0. The message to be sent is the

following.

[$7E][$80][$01][$32][$B3]

Instruction Code Length (bytes)

LD Pa.y 0 2

LDN Pa.y 1 2

OUT Pa.y 2 2

OUTN Pa.y 3 2

AND Pa.y 4 2

ANDN Pa.y 5 2

OR Pa.y 6 2

ORN Pa.y 7 2

ADD Pa, Pb, Pc 8 4

SUB Pa, Pb, Pc 9 4

MUL Pa, Pb, Pc 10 4

DIV Pa, Pb, Pc 11 4

SET Pa.y 12 2

RES Pa.y 13 2

FIN b40.y/b150.y 14 2

END 15 2

Loading...

Loading...