SECTION VI

MAINTENANCE AND TROUBLESHOOTING

6.1

INTRODUCTION

This section provides information necessary to perform electrical and mechanical

adjustments, parts replacement, and troubleshooting. Sections

IV

and V contain the

theory of operation of components and circuits

for

reference.

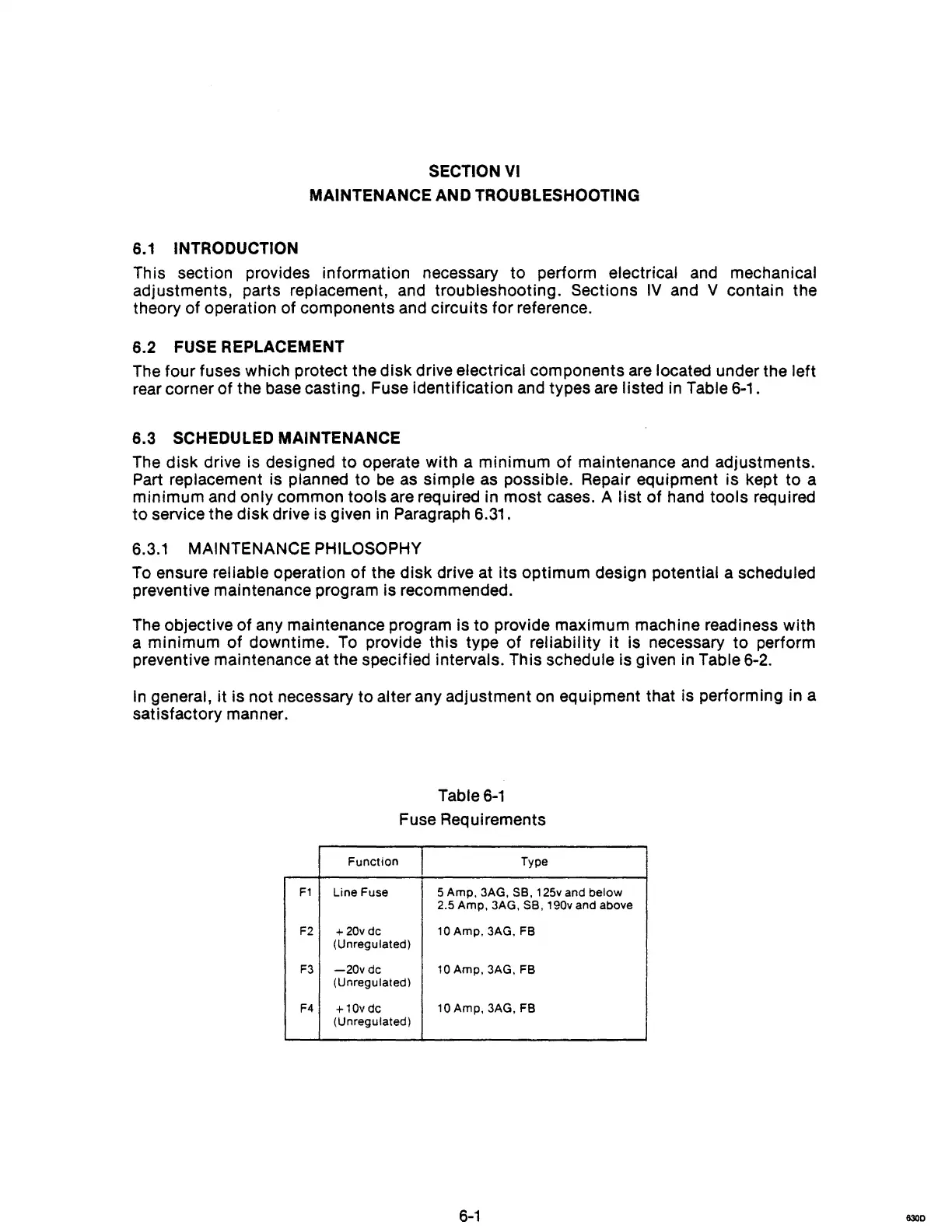

6.2 FUSE REPLACEMENT

The four fuses which protect the disk drive electrical components

are

located under the left

rear corner of the base casting. Fuse identification and types are listed in Table 6-1.

6.3

SCHEDULED MAINTENANCE

The

disk drive is designed

to

operate with a minimum

of

maintenance and adjustments.

Part replacement is planned to

be

as

simple as possible. Repair equipment is kept to a

minimum and only common tools are required in most cases.

A

list

of hand tools required

to

service the disk drive is given in Paragraph 6.31.

6.3.1

MAINTENANCE PHILOSOPHY

To

ensure reliable operation

of

the disk drive at its optimum design potential a scheduled

preventive maintenance program is recommended.

The

objective

of

any maintenance program is to provide maximum machine readiness with

a minimum

of

downtime.

To

provide this type of reliability

it

is necessary

to

perform

preventive maintenance at the specified intervals. This schedule is given in Table 6-2.

In

general,

it

is not necessary

to

alter any adjustment on equipment that is performing in a

satisfactory manner.

Table

6-1

Fuse Requirements

Function

Type

F1

Line Fuse 5 Amp. 3AG. SB. 125v and below

2.5 Amp. 3AG.

SB. 190v and above

F2

+

20v

dc 10 Amp. 3AG. FB

(Unregulated)

F3

-20vdc

10 Amp. 3AG. FB

(Unregulated)

F4

+10vdc

10 Amp, 3AG, FB

(Unregulated)

6-1

630D

Loading...

Loading...