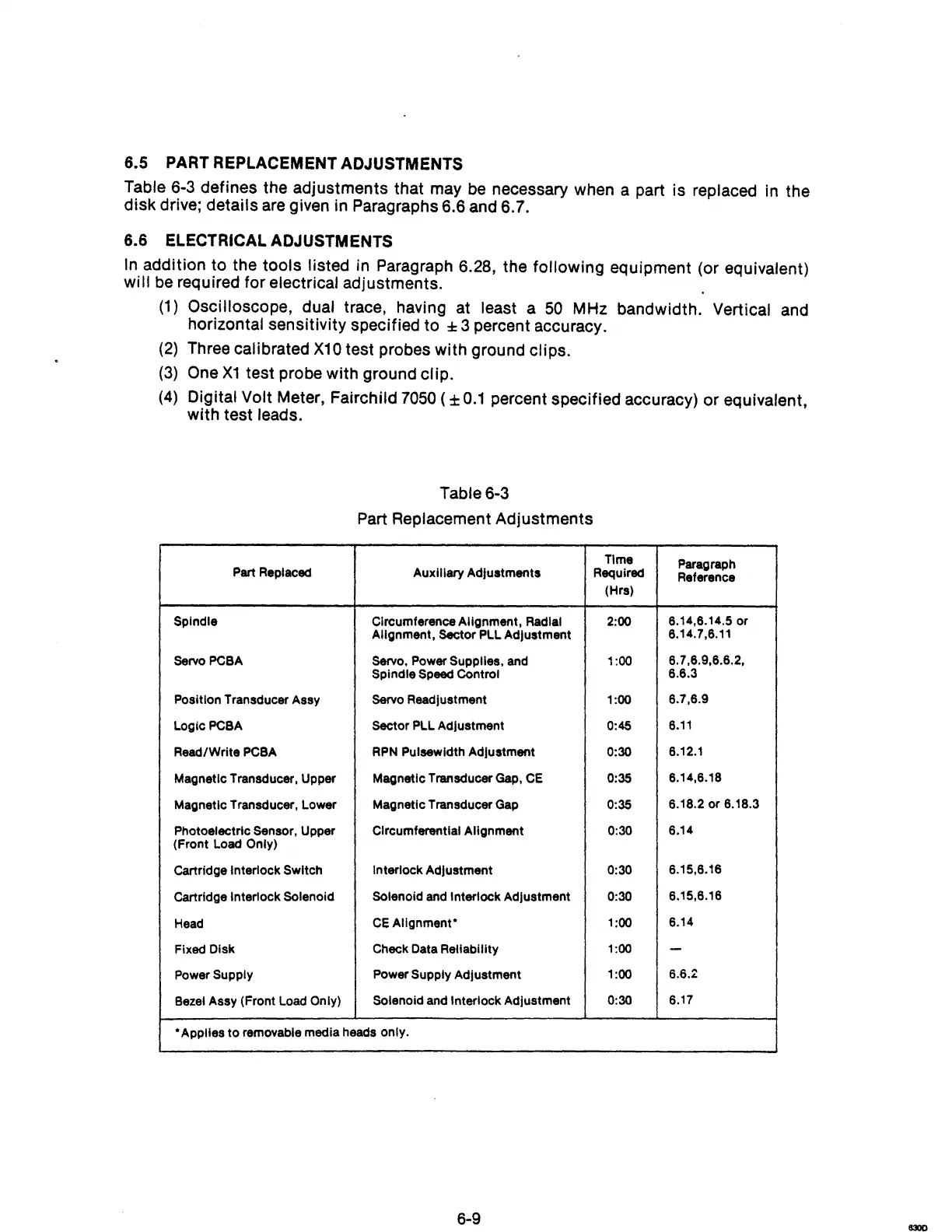

6.5 PART REPLACEMENT ADJUSTMENTS

Table 6-3 defines the adjustments that may

be

necessary when a part is replaced in the

disk drive; details are given in Paragraphs 6.6 and 6.7.

6.6 ELECTRICAL ADJUSTMENTS

In

addition to the tools listed in Paragraph 6.28, the following equipment (or equivalent)

will

be

required for electrical adjustments.

(1)

Oscilloscope, dual trace, having at least a

50

MHz bandwidth. Vertical and

horizontal sensitivity specified to

± 3 percent accuracy.

(2)

Three calibrated

X10

test probes with ground clips.

(3)

One

X1

test probe with ground clip.

(4)

Digital Volt Meter, Fairchild

7050

( ±

0.1

percent specified accuracy) or equivalent,

with test leads.

Table 6-3

Part Replacement Adjustments

Time

Paragraph

Part Replaced

Auxiliary Adjustments Required

Reference

(Hrs)

Spindle

Circumference Alignment, Radial 2:00

6.14,6.14.5 or

Alignment, Sector PLL Adjustment

6.14.7,6.11

Servo PCBA Servo, Power

Supplies, and 1:00

6.7,6.9,6.6.2,

Spindle Speed Control

6.6.3

Position Transducer Assy Servo Readjustment 1:00

6.7,6.9

LogicPCBA

Sector PLL Adjustment

0:45

6.11

Read/Write PCBA

RPN

Pulsewldth Adjustment 0:30

6.12.1

Magnetic Transducer, Upper

Magnetic Transducer Gap,

CE

0:35

6.14,6.18

Magnetic Transducer, Lower Magnetic Transducer Gap

0:35

6.18.2 or 6.18.3

Photoelectric Sensor, Upper Circumferential Alignment 0:30

6.14

(Front Load Only)

Cartridge Interlock Switch

Interlock

Adjustment 0:30

6.15,6.16

Cartridge Interlock Solenoid Solenoid and Interlock Adjustment 0:30

6.15,6.16

Head

CE

Alignment'

1:00

6.14

Fixed Disk

Check Data Reliability 1:00

-

Power Supply Power Supply Adjustment

1:00

6.6.2

Bezel Assy (Front Load

Only)

Solenoid and Interlock Adjustment 0:30

6.17

• Applies

to

removable media heads only.

6-9

Loading...

Loading...