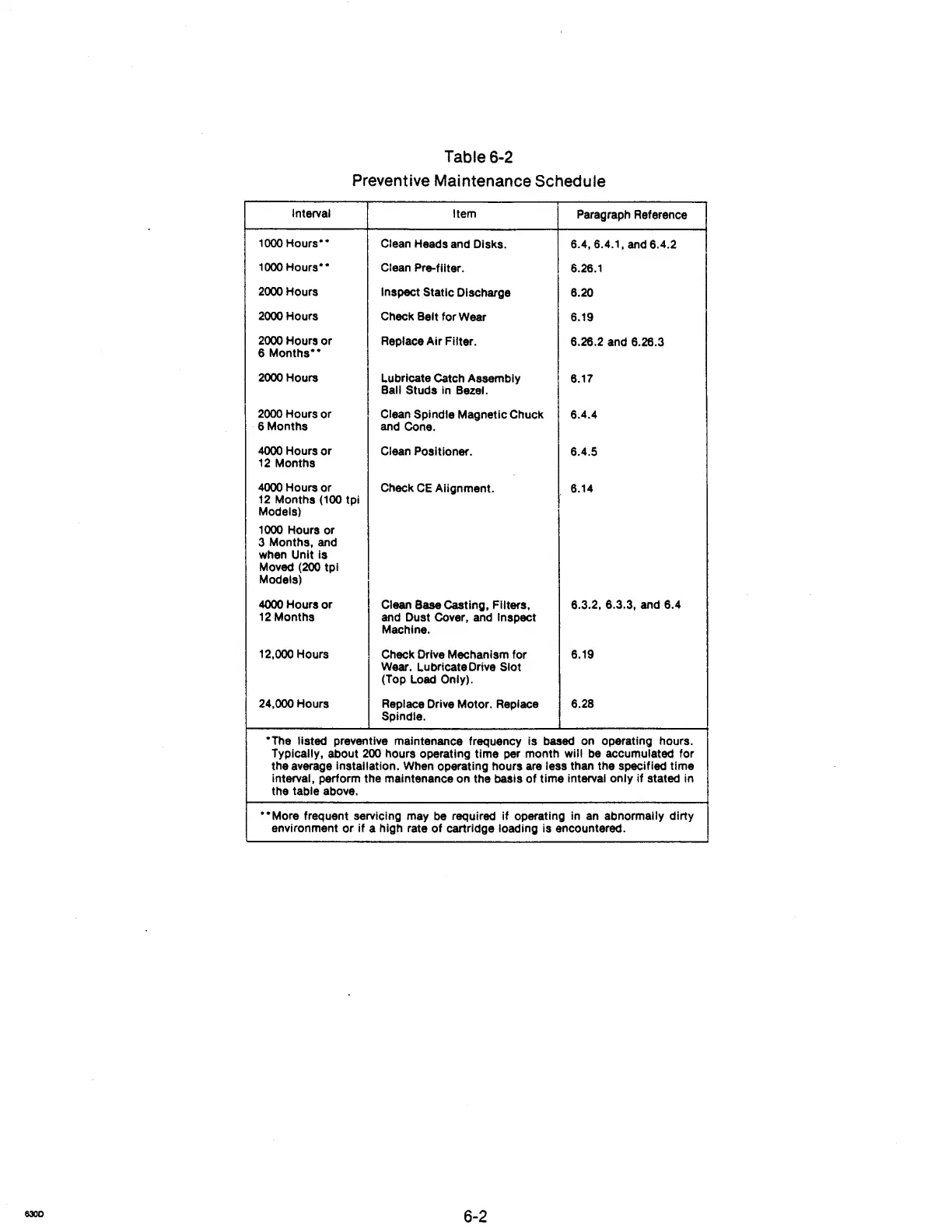

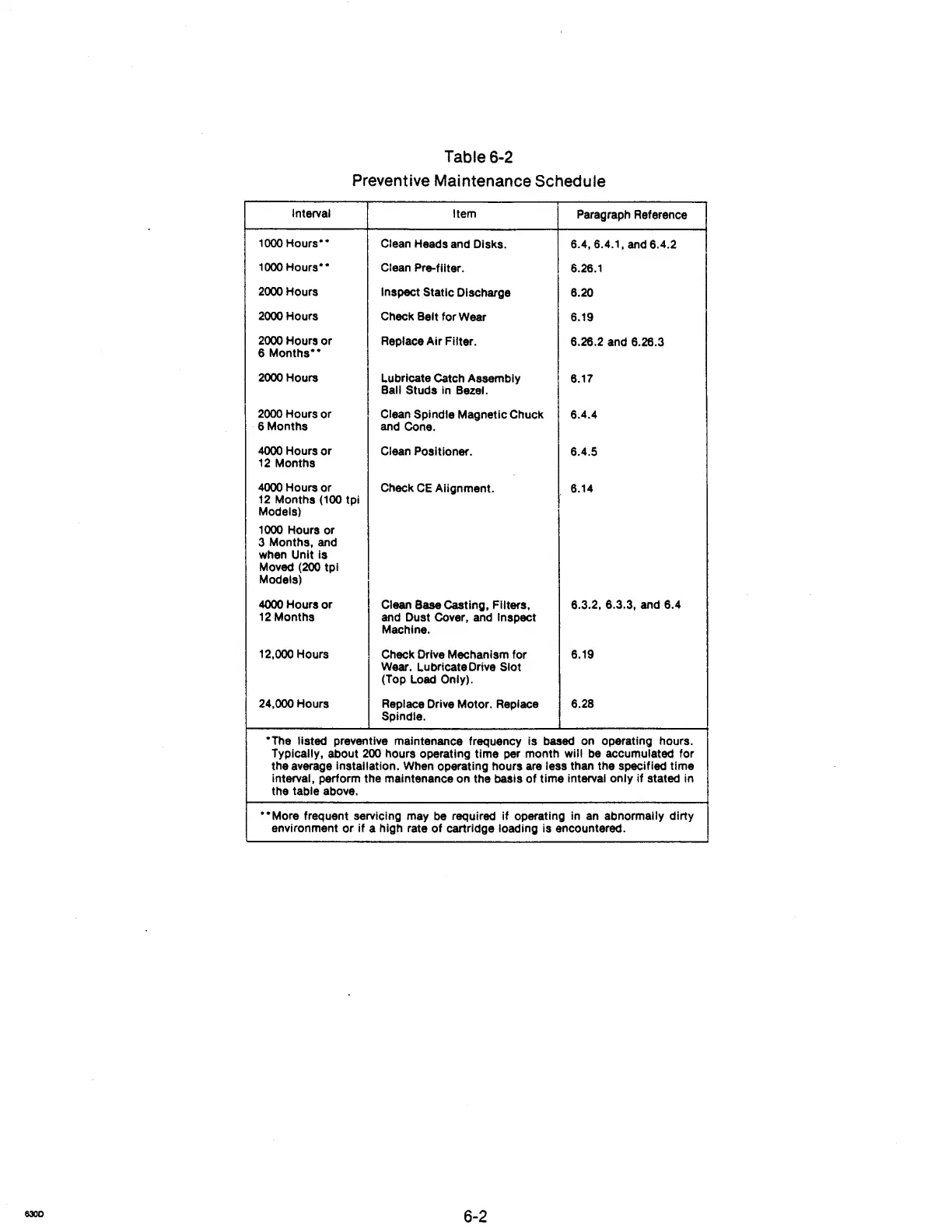

Table 6-2

Preventive Maintenance

Schedule

Interval Item

Paragraph Reference

1000

Hours··

Clean Heads and Disks.

6.4, 6.4.1, and 6.4.2

1000

Hours··

Clean Pre-filter.

6.26.1

2000 Hours

Inspect Static Discharge

6.20

2000 Hours

Check

Belt

for

Wear

6.19

2000 Hours

or

Replace

Air

Filter.

6.26.2 and 6.26.3

6

Months·'

2000 Hours

Lubricate Catch

Assembly

6.17

Ball

Studs

In Bezel.

2000 Hours

or

Clean Spindle Magnetic Chuck

6.4.4

6 Montha

and Cone.

4000 Hours

or

Clean Positioner.

6.4.5

12

Months

4000 Hours

or

12

Months

(100

tpl

Check

CE

Alignment.

6.14

Models)

1000 Hours

or

3

Months,

and

when

Unit

Is

Moved (200

tpl

Models)

4000 Hours

or

Clean

Bue

Casting, Filters, 6.3.2, 6.3.3, and 6.4

12

Months

and Dust Cover, and Inspect

Mechlne.

12,000 Hours

Check Drive Mechanism

for

6.19

Wear. LubricateDrive

Slot

(Top Load Only).

24,000 Hours

Replace Drive Motor. Replace

6.28

Spindle.

'The

listed preventive maintenance frequency Is

based

on operating hours.

Typically, about 200

hours

operating

time

per

month

will

be accumulated

for

the

average Installation. When operating

hours

ara less than

the

specified

time

interval, perform the maintenance

on

the baals

of

time

interval

only

if

stated

in

the table above •

••

More frequent servicing may be required

if

operating In an abnormally

dirty

environment

or

if

a

high

rate

of

cartridge loeding Is encountered.

6300

6-2

Loading...

Loading...