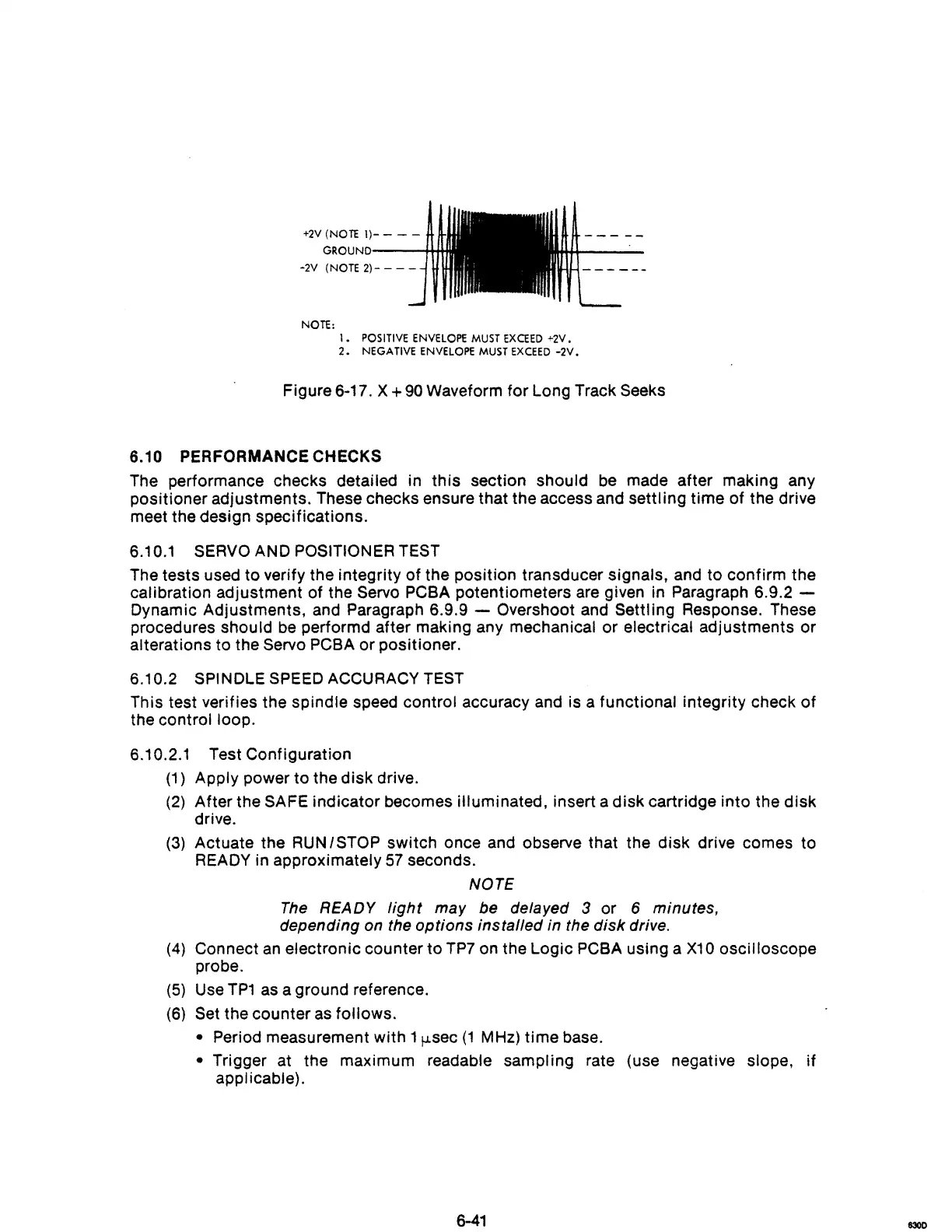

+2V

(NOTE

1)-

- - -

GROUND----++*,

-2V (NOTE

2)-

- - -

NOTE:

I.

POSITIVE

ENVELOPE

MUST

EXCEED

+2V.

2.

NEGA

TIVE

ENVELOPE

MUST

EXCEED

-2V.

Figure 6-17. X + 90 Waveform

for

Long Track Seeks

6.10

PERFORMANCE CHECKS

The performance checks detailed in

this

section

should

be made

after

making

any

pOSitioner

adjustments.

These checks ensure

that

the access and

settling

time

of

the drive

meet

the

deSign

specifications.

6.10.1 SERVO AND POSITIONER TEST

The

tests

used

to

verify the

integrity

of

the

position

transducer

signals,

and

to

confirm

the

calibration

adjustment

of

the Servo PCBA

potentiometers

are given in Paragraph 6.9.2 -

Dynamic

Adjustments,

and Paragraph 6.9.9 - Overshoot and

Settling

Response. These

procedures

should

be performd

after

making any mechanical

or

electrical

adjustments

or

alterations

to

the Servo PCBA

or

pOSitioner.

6.10.2 SPINDLE SPEED ACCURACY TEST

This test verifies

the

spindle

speed

control

accuracy and is a

functional

integrity

check

of

the

control

loop.

6.10.2.1

(1

)

(2)

Test

Configuration

Apply

power

to

the

disk

drive.

After

the SAFE

indicator

becomes

illuminated,

insert a

disk

cartridge

into

the

disk

drive.

(3)

Actuate

the

RUN I STOP

switch

once and observe that the

disk

drive

comes

to

READY in

approximately

57

seconds.

NOTE

The

READY

light

may be delayed 3

or

6 minutes,

depending on the

options

installed

in the

disk

drive.

(4) Connect

an

electronic

counter

to

TP7 on the

Logic

PCBA using a

X10

oscilloscope

probe.

(5)

Use

TP1

as a ground reference.

(6) Set the

counter

as

follows.

• Period measurement

with

1

f-Lsec

(1

MHz)

time

base.

• Trigger at the

maximum

readable

sampling

rate (use negative slope,

if

applicable).

6-41

8300

Loading...

Loading...