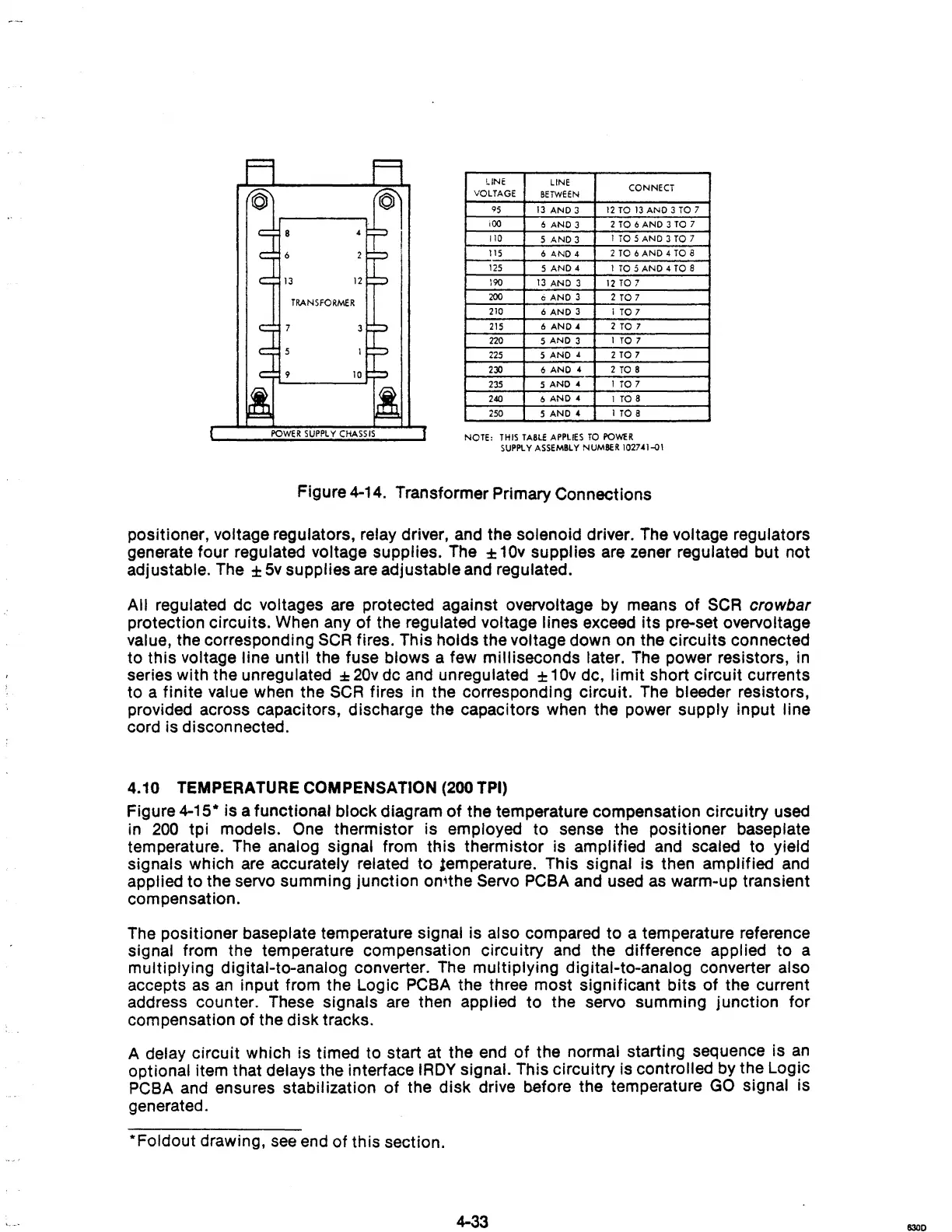

LINE

LINE

CONNECT

VOLTAGE

BETWEEN

95

13

AND

3

12

TO

13

AND

3

TO

7

;00

6

AND

3

2

TO

6

AND

3

TO

7

110

5

AND

3

I

TO

5

AND

3

TO

7

l1S

6

AND

4

2

TO

6

AND

4

TO

a

125

5

AND

4 1

TO

5

AND

4

TO

8

:90

13

AND

3

12

TO

7

200

6

AND

3 2

TO

7

210

6 AND J

I

TO

7

215

6

AND

~

2

TO

7

220

5

AND

3 I

TO

7

225

5

AND

4

2

TO

7

230

6

AND

4 2

TO

8

235

5 AND 4 1

TO

7

2~

6 AND 4

I

TO

8

250

5 AND

~

I

TO

a

NOTE,

THIS

TABLE

APPLIES

TO

POWER

SUPPLY

ASSEMBLY

NUMBER

1027~I-01

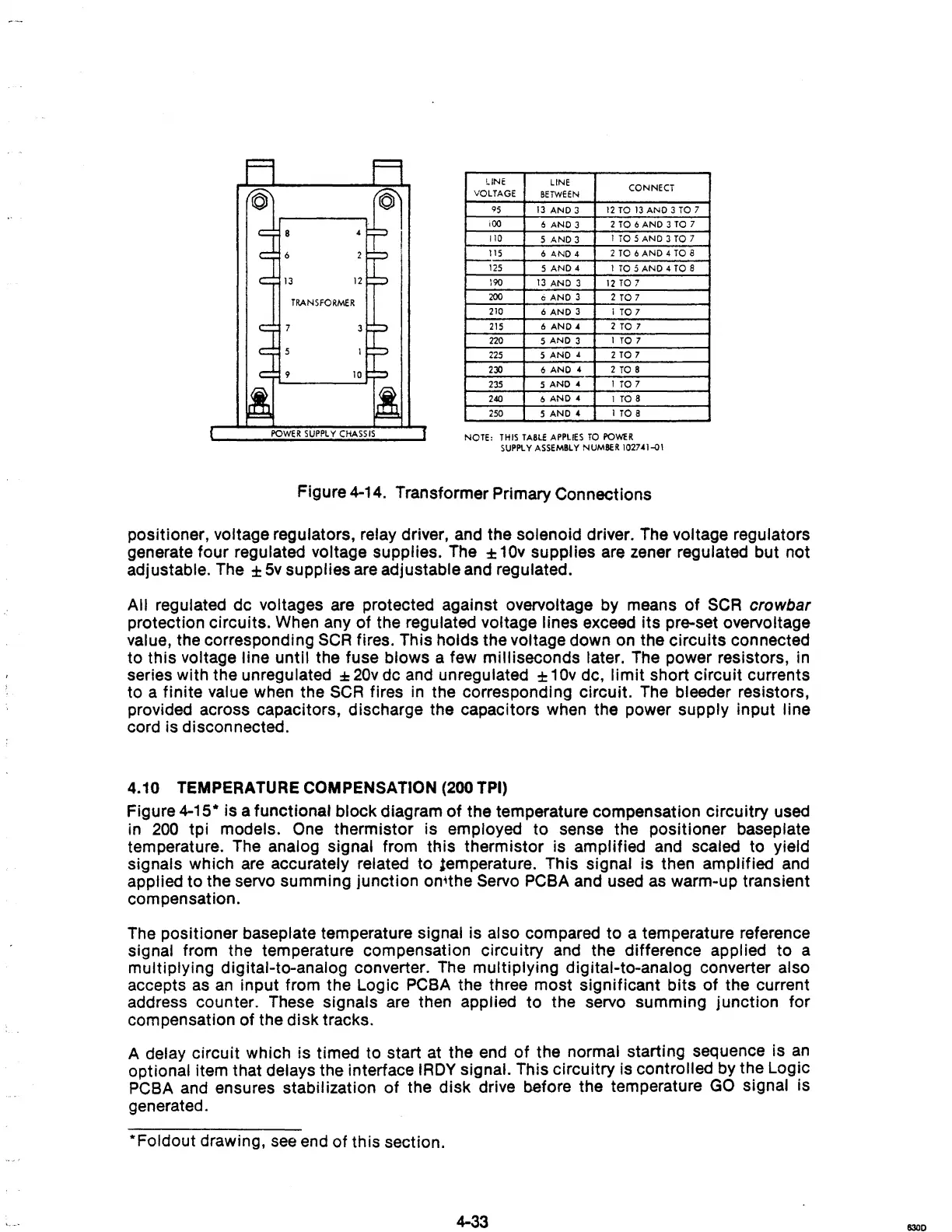

Figure 4-14. Transformer Primary Connections

positioner, voltage regulators, relay driver, and the solenoid driver. The voltage regulators

generate four regulated voltage

supplies. The ± 10v supplies are zener regulated but not

adjustable. The

±

Sv

supplies are adjustable and regulated.

All regulated dc voltages are protected against overvoltage by means

of

SCR

crowbar

protection circuits. When any

of

the regulated voltage lines exceed its pre-set overvoltage

value, the corresponding

SeR fires. This holds the voltage down on the circuits connected

to this voltage

line until the fuse blows a few milliseconds later. The power resistors, in

series with the unregulated

±

20v

dc and unregulated ± 1

Ov

dc,

limit

short

circuit

currents

to a finite

value when the

SCR

fires in the corresponding circuit. The bleeder resistors,

provided across capacitors, discharge the capacitors when the power supply input

line

cord is disconnected.

4.10 TEMPERATURE COMPENSATION (200 TPI)

Figure 4-1S* is a functional block diagram

of

the temperature compensation circuitry used

in

200

tpi models. One thermistor is employed to sense the positioner baseplate

temperature. The analog signal from this thermistor is amplified and scaled to

yield

signals which are accurately related to temperature. This signal is then amplified and

applied to the servo summing junction

on

1

the Servo PCBA and used as warm-up transient

compensation.

The positioner baseplate temperature

Signal is also compared

to

a temperature reference

Signal from the temperature compensation circuitry and the difference applied to a

multiplying digital-to-analog converter. The multiplying digital-to-analog converter

also

accepts as

an

input from the Logic PCBA the three most significant

bits

of

the current

address counter. These Signals are then applied to the servo summing

junction

for

compensation

of

the

disk

tracks.

A

delay circuit which is timed to start at the end

of

the normal starting sequence is

an

optional item that delays the interface

IRDY

signal. This circuitry is controlled by the LogiC

PCBA and ensures stabil ization

of

the disk drive before the temperature

GO

signal is

generated.

*Foldout drawing,

see

end

of

this section.

4-33

6300

Loading...

Loading...