830D

6.18 MAGNETIC TRANSDUCER

GAP

Magnetic transducers

are

used

in

one place

on

front load models, and are used in two

places

on

top load models.

In

each case the distance between the transducer pole tip and

its respective rotating surface must

be

precisely controlled to produce acceptable signal

levels.

Paragraphs 6.18.1 and 6.18.2 describe the test

and

adjustment procedures for the upper

and lower transducers, respectively,

on

top loading disk drives. Paragraph 6.18.3 provides

test and adjustment instructions for front loading disk drives.

6.18.1

UPPER

TRANSDUCER

TEST

AND ADJUSTMENT -

TOP

LOAD MODELS

Extend the unit forward out of the rack and install the Adapter Bowl Setup Tool

(PERTEC

Part No.1

03619-01)

onto the spindle cone. Exercise care to ensure that cone

and

tool

are

clean

and

free

of

dirt.

CAUTION

WHEN GAUGING

GAP

CLEARANCE, ENSURE THAT NO

DAMAGE

IS

MADE

TO

THE SENSING TIP

OF

THE

TRANSDUCER

BY

THE FEELER GAUGE.

A feeler gauge

Is

used to measure the gap distance between the transducer pole

tip

and

the tool.

See

Figure 6-35.

Each

adapter bowl setup tool will have marked

on

it

a calibration

value to be added to the nominal feeler gauge value.

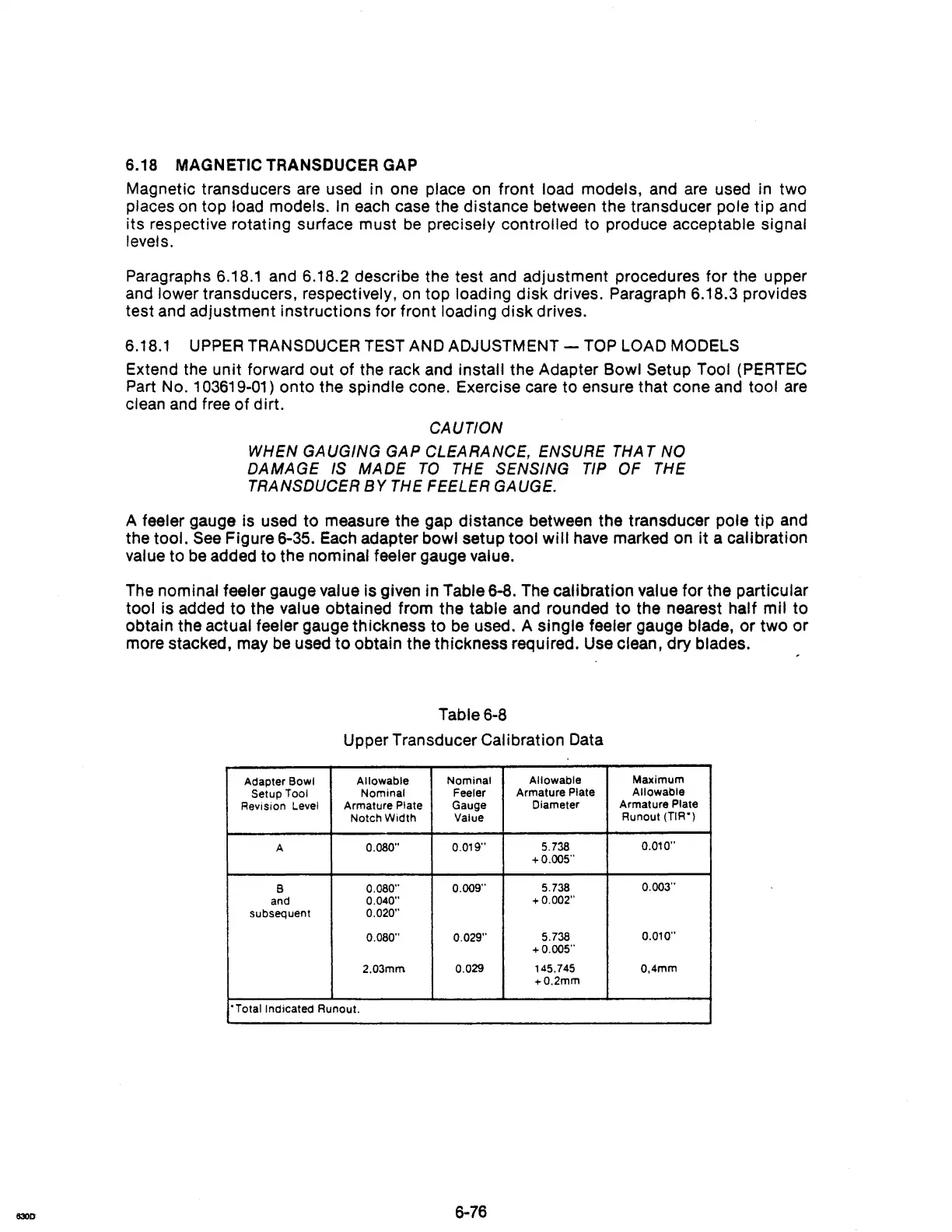

The

nominal feeler gauge value is given in Table 6-8. The calibration value for the particular

tool is added to the value obtained from the table and rounded

to

the nearest half mil to

obtain the actual feeler gauge thickness to

be

used. A single feeler gauge blade, or two or

more stacked, may

be

used

to

obtain the thickness required. Use clean, dry blades.

Table

6-8

Upper Transducer Calibration Data

Adapter Bowl

Allowable

Nominal

Allowable

Maximum

Setup

Tool

Nominal

Feeler

Armature Plate

Allowable

Revision Level

Armature Plate

Gauge

Diameter

Armature Plate

Notch Width

Value

Runout

(TlR')

A

0.080"

0.019"

5.738

0.010"

+0.005"

B

O.OSO"

0.009"

5.738

0.003"

and

0.040"

+0.002"

subsequent

0.020"

0.080" 0.029"

5.738

0.010"

+0.005"

2.03mm 0.029

145.745 0.4mm

+0.2mm

'Totallndicated

Runout.

6-76

Loading...

Loading...