6.12.2 'ONES' WINDOW SETTING

6.12.2.1 Test Configuration

(1)

Remove the interface connector and terminator

PCBA

from connector

J101

and

J102

on the Logic PCBA.

(2)

Connect a disk exerciser having read/write capability

to

J101

or J102

on

the Logic

PCBA.

(3)

Apply power to the exerciser and the disk drive. Observe that the

READY

indicator

is

illuminated; allow a 5-minute warm up period.

(4)

Write

an

all-zeros pattern via the disk exerciser.

(5)

Connect oscilloscope Channel 1 probe

to

TP25.

Connect the test probe ground

clip to ground reference

TP17.

(6)

Set oscilloscope Channel 1 sensitivity to

0.1

Ov

per division.

(7)

Set sync to internal, normal mode.

(8)

Set oscilloscope to trigger

on

the positive slope

of

RPN.

(9)

Connect oscilloscope Channel 2 probe to

TP23.

Connect the

te~t

probe ground

clip to ground reference

TP17.

(10)

Set oscilloscope Channel 2 sensitivity to

0.1

Ov

per division.

6.12.2.2 Test And Adjustment Procedure (Long)

(1)

Observe 'ones' window on oscilloscope Channel 2

(TP23)

as shown in Figure 6-19.

(2)

Measure the adjusted internal, i.e., leading edge

of

RPN

TP25

to trailing edge

of

'ones' window

TP23.

(3)

If the pulsewidth is not within

.:1:.5

nsec

(2400

rpm)

or

.:1:.8

nsec

(1500

rpm) of

setting,

listed

in

Table 6-5, adjust

R115

until readings

are

within

.:1:.3

nsec

(2400

rpm)

or

.:1:.5

nsec

(1500

rpm).

6.12.2.3 Test And Adjustment Procedure (Short)

(1)

Write all 'ones' pattern via the disk exerciser.

(2)

Observe 'ones' window

on

oscilloscope Channel 2

(TP23)

as shown in Figure 6-19.

(2)

Measure the adjusted interval, i.e., leading edge

of

RPN

TP25

to trailing edge

of

'ones' window (TP23).

(4)

If the pulsewidth is not within

±o5

nsec

(2400

rpm)

or

.:1:.8

nsec

(1500

rpm) of

setting listed in

Table 6-5, adjust

R113

until readings are within =.3 nsec

(2400

rpm)

or

::

3 nsec

(1500

rpm).

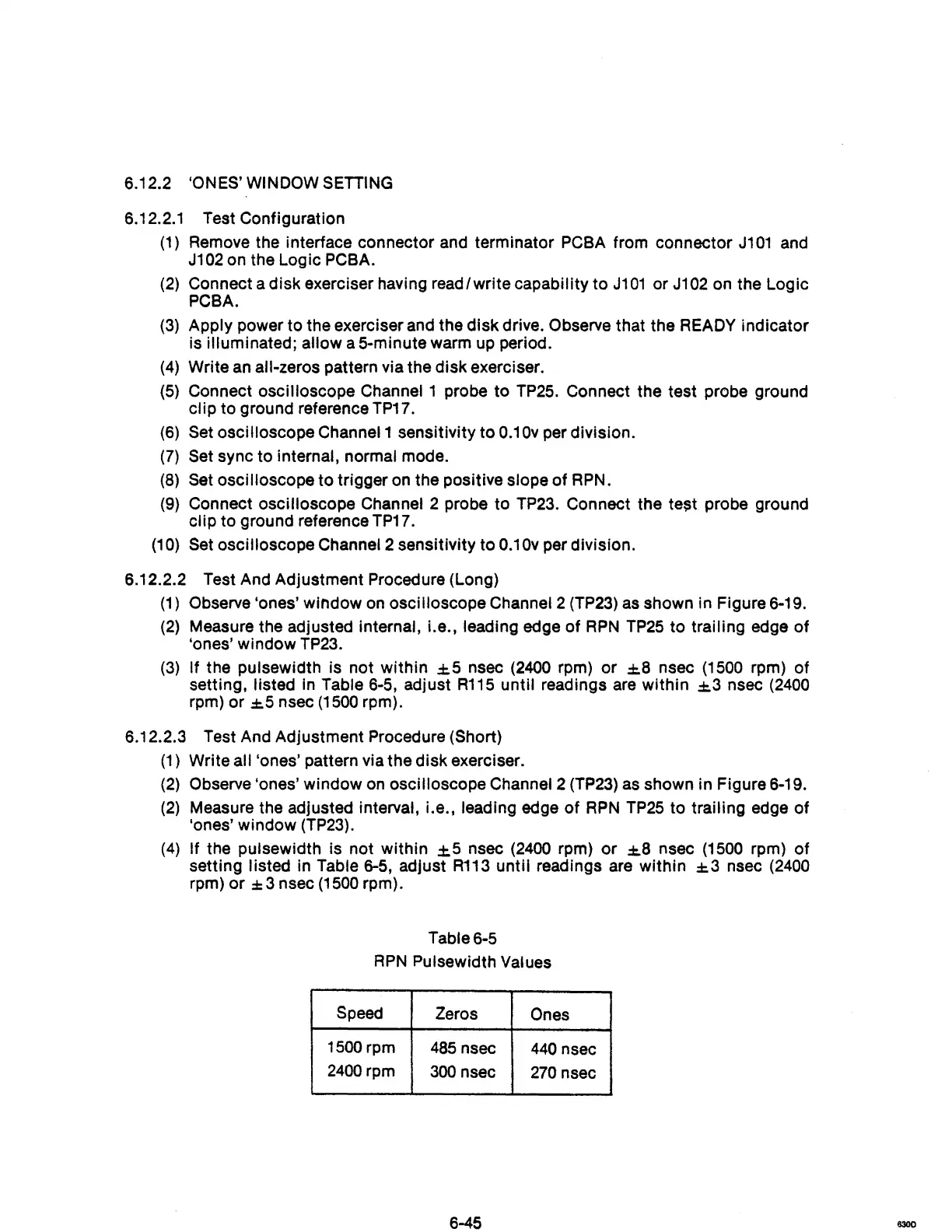

Table 6-5

RPN

Pulsewidth Values

Speed

Zeros

Ones

1500 rpm

485

nsec

440

nsec

2400

rpm

300

nsec

270

nsec

6-45

6300

Loading...

Loading...