(6)

Set

oscilloscope

as

follows

• Voltage

sensitivity to 0.2v per division

if

the

X10

probe is used.

• Select dc input mode.

•

Sweep

rate to

0.1

msec per division.

•

Set

to normal trigger mode.

• .

Use

internal sync

and

set to trigger

on

negative slope.

6.6.3.2 Test Procedure

(1)

Establish test configuration described

in

Paragraph 6.6.3.1.

(2)

Select Channel 1

on

the oscilloscope.

(3)

Ground

U19A-2

(NLDMEG) on the Servo PCBA.

(4)

Apply power to the disk drive.

6.6.3.3 Adjustment Procedure

(1)

Establish test configuration described

in

Paragraph 6.6.3.1.

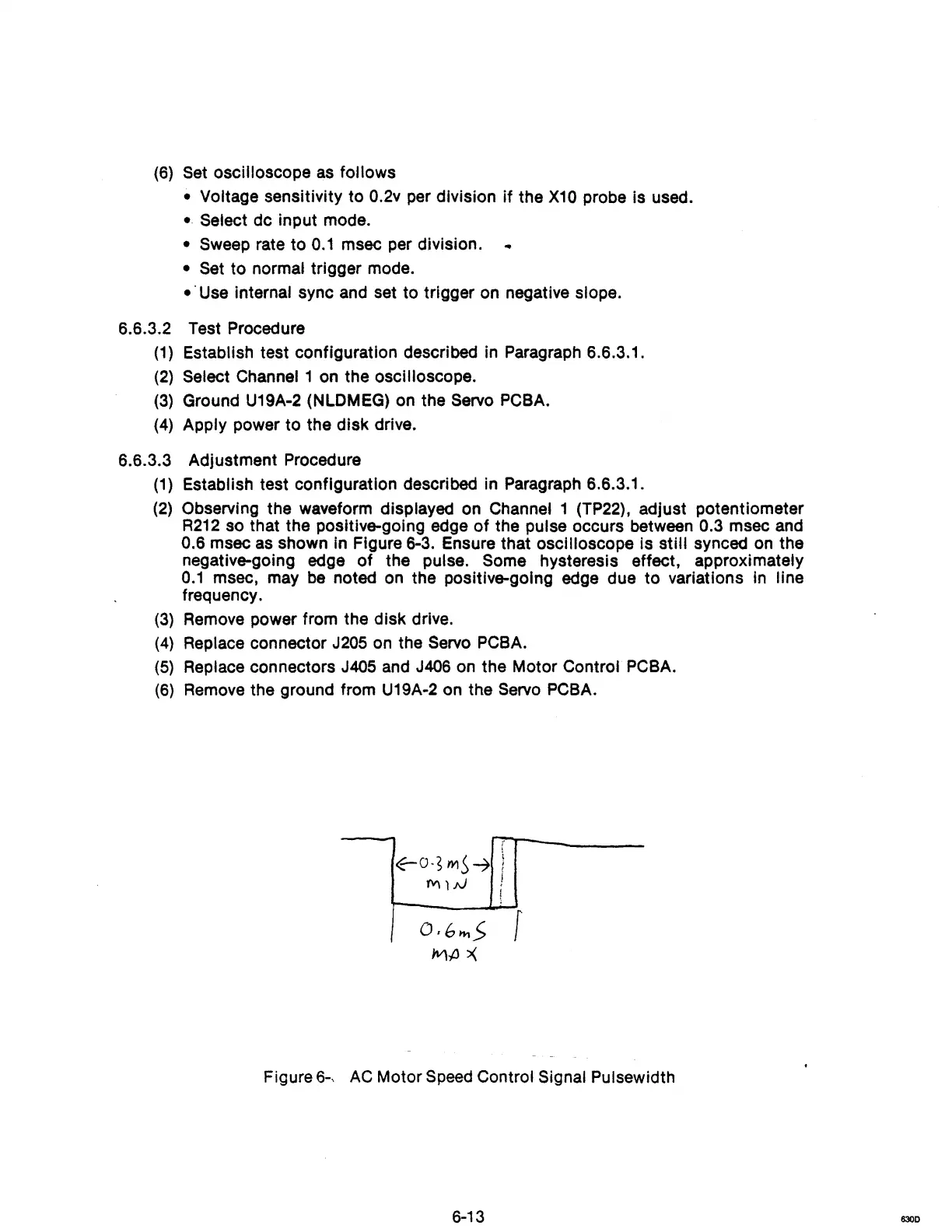

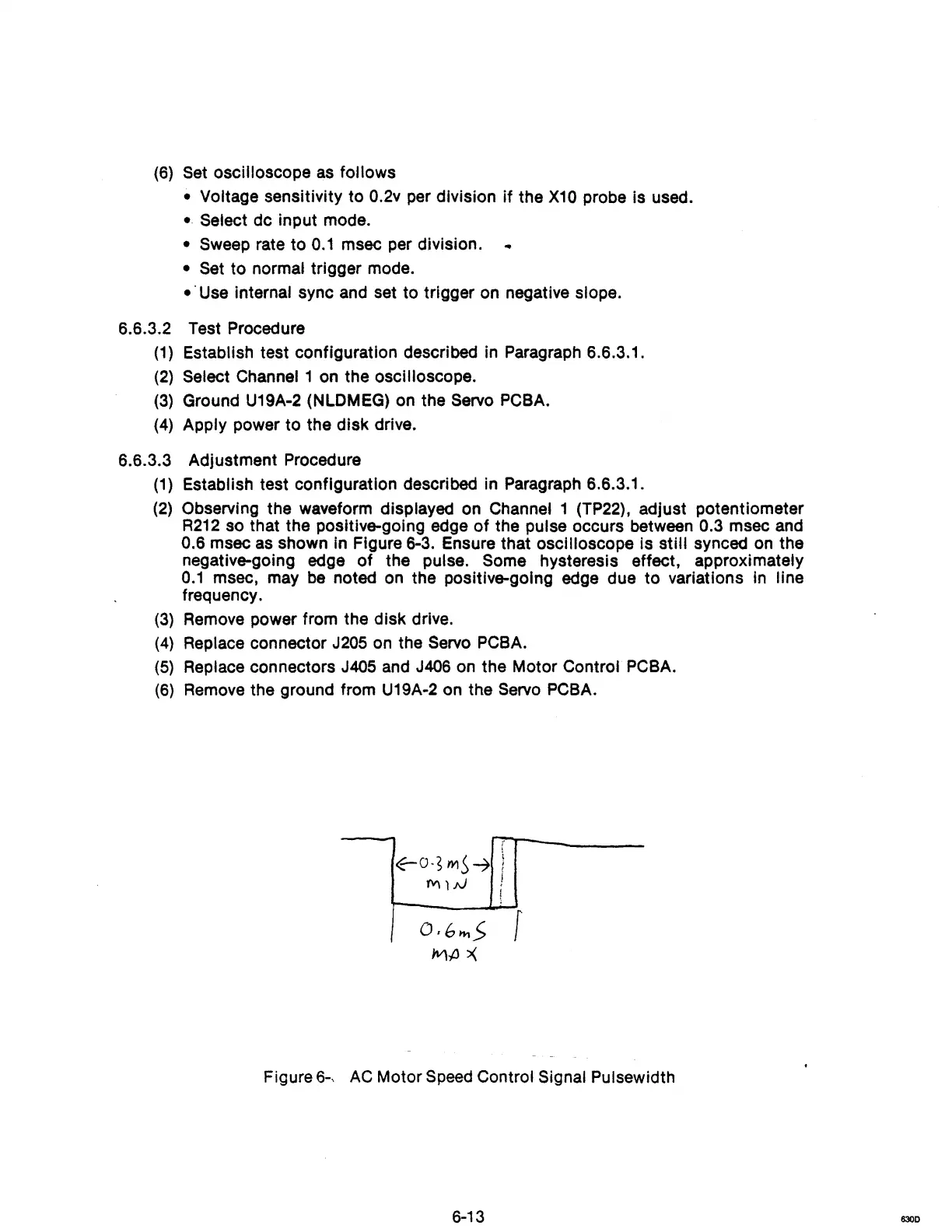

(2)

Observing the waveform displayed on Channel 1

(TP22),

adjust potentiometer

R212

so that the positive-going edge

of

the pulse occurs between 0.3 msec

and

0.6 msec

as

shown

In

Figure 6-3. Ensure that oscilloscope Is still synced

on

the

negative-going edge of the pulse.

Some hysteresis effect, approximately

0.1

msec, may

be

noted

on

the positive-going edge due to variations

in

line

frequency.

(3)

Remove

power from the disk drive.

(4) Replace connector J205

on

the Servo

PCBA.

(5) Replace connectors J405

and

J406

on

the Motor Control

PCBA.

(6)

Remove

the ground from

U19A-2

on

the

Servo

PCBA.

Figure 6-,

AC

Motor

Speed

Control Signal Pulsewidth

6-13

6300

Loading...

Loading...