6300

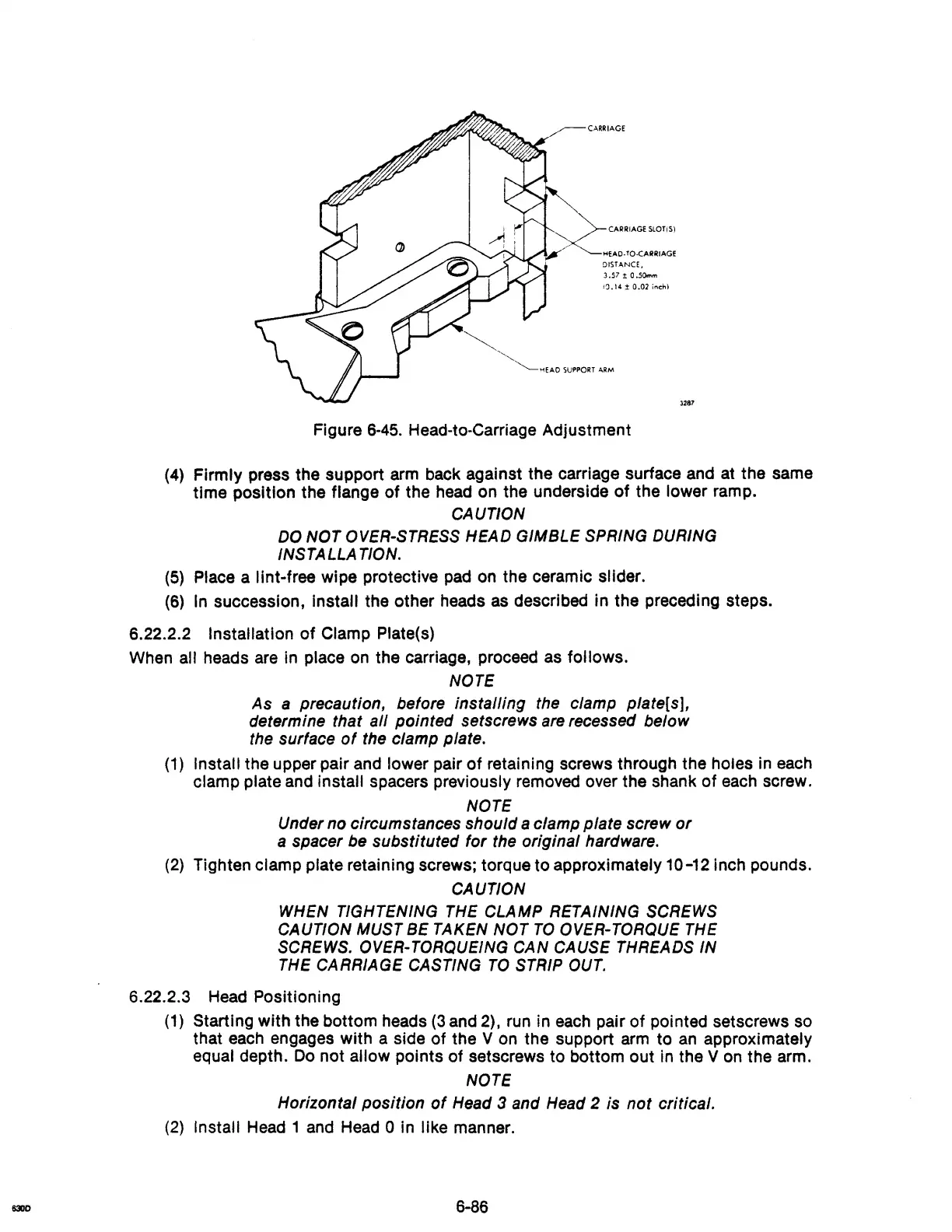

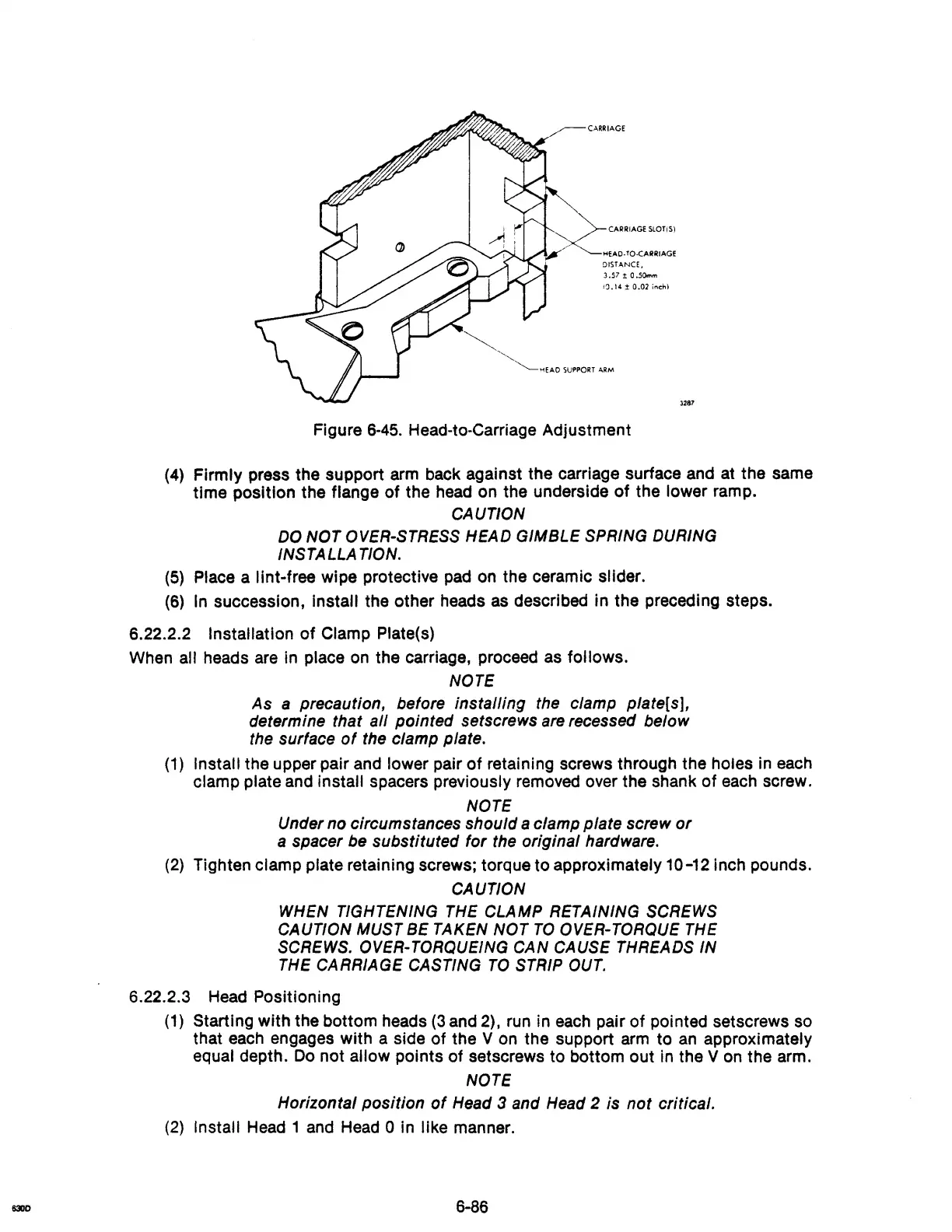

CARRIAGE

CARRIAGE SLOTiS)

HEAO· TO.cARRIAGE

DISTANCE.

3.57

1; O.sOmm

IQ.14

±

0.02

inch}

~

~~EAO

SUPPORT

ARM

Figure 6-45. Head-to-Carriage

Adjustment

3287

(4)

Firmly

press

the

support

arm back

against

the

carriage surface and at

the

same

time

position

the

flange

of

the

head

on

the

underside

of

the

lower

ramp.

CAUTION

DO

NOT

OVER-STRESS HEAD

GIMBLE

SPRING DURING

INSTALLA TION.

(5) Place a

lint-free

wipe

protective pad on

the

ceramic slider.

(6) In succession, Install

the

other

heads as described

in

the

preceding steps.

6.22.2.2 Installation

of

Clamp Plate(s)

When

all heads are In place on

the

carriage, proceed as

follows.

NOTE

As

a precaution. before installing the clamp plate[s].

determine that

al/ pointed setscrews

are

recessed below

the surface

of

the clamp plate.

(1) Install

the

upper

pair

and

lower

pair

of

retaining screws

through

the

holes in each

clamp

plate and

install

spacers previously removed over

the

shank

of

each screw.

NOTE

Under

no

circumstances should a clamp plate screw

or

a spacer be substituted for the original hardware.

(2)

Tighten

clamp

plate retaining screws;

torque

to

approximately

10-12 Inch pounds.

CAUTION

WHEN TIGHTENING THE CLAMP RETAINING SCREWS

CAUTION MUST

BE TAKEN

NOT

TO

OVER-TORQUE THE

SCREWS. OVER-TORQUEING

CAN

CAUSE THREADS IN

THE CARRIAGE

CASTING

TO

STRIP OUT.

6.22.2.3 Head POSitioning

(1) Starting

with

the

bottom

heads (3 and 2), run in each

pair

of

pointed setscrews so

that each engages

with

a

side

of

the

V on

the

support

arm

to

an approximately

equal depth. Do

not

allow

pOints

of

setscrews

to

bottom

out

in

the

Von

the

arm.

NOTE

Horizontal position

of

Head 3 and Head 2 is

not

critical.

(2) Install Head 1 and Head 0 in

like

manner.

6-86

Loading...

Loading...