OOOI~INIIC

....

,

,

,

I

, I

.~

I

."

\.-----.l------.u.,---

\..

~'

~i

~

\

.//

/if"'-

.'CI.lI(U:

\

..........

, D

(:lt1tN)tON

..

:;....:

,.":~

SRIINO

,

::

:

....

,.

:

...,

I I

--~-----~----~------

-

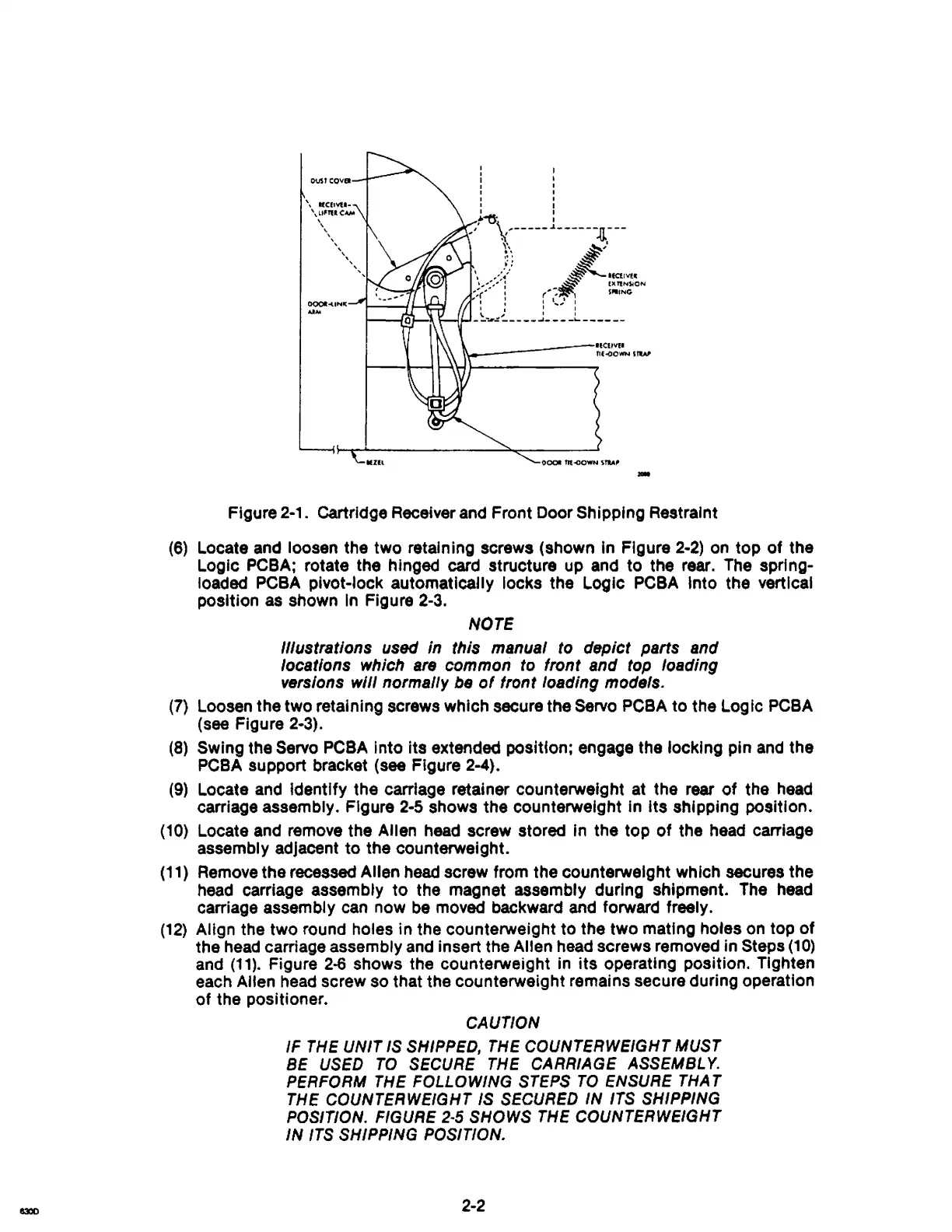

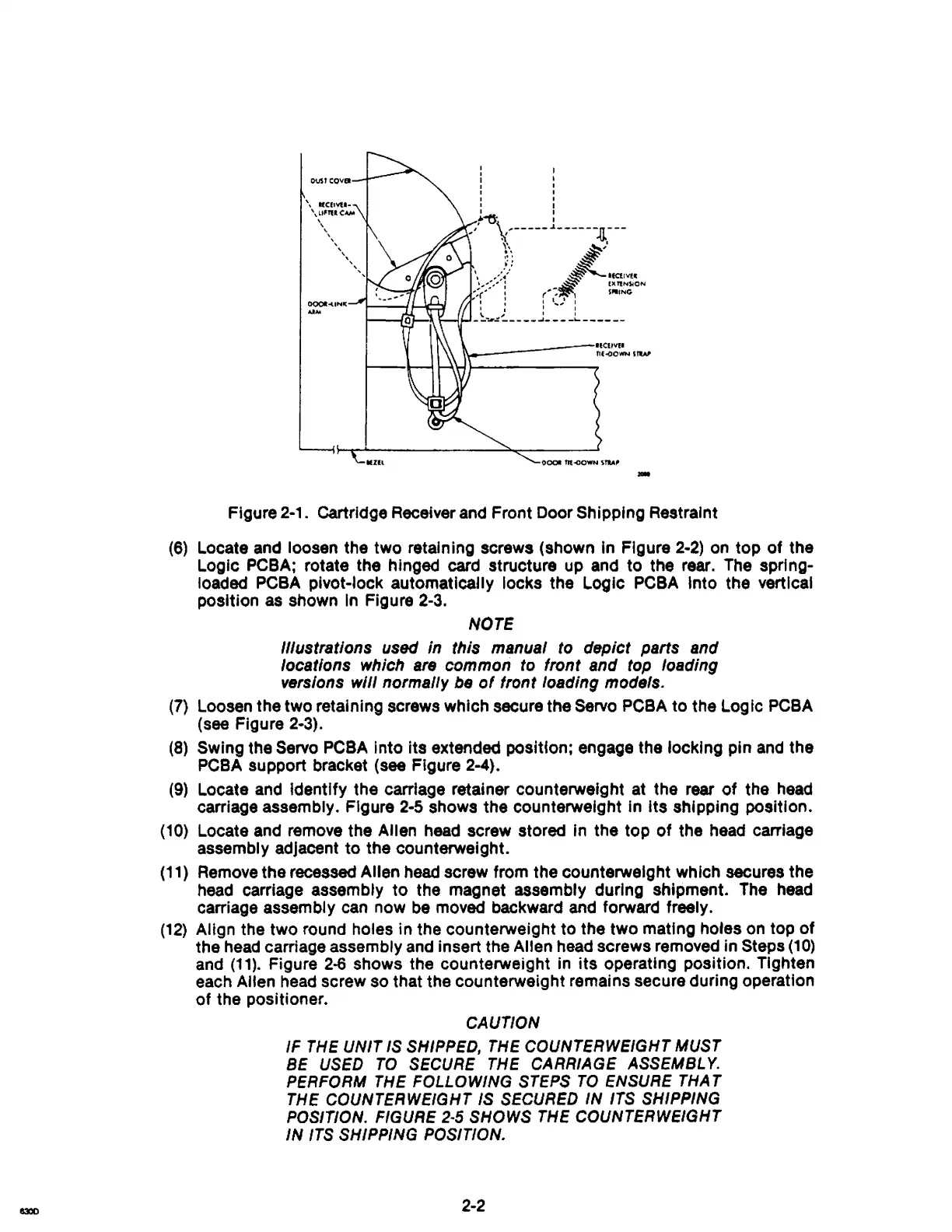

Figure 2-1. cartridge Receiver and Front Door Shipping Restraint

(6)

Locate and loosen the two retaining screws (shown in Figure

2-2)

on

top

of

the

Logic PCBA; rotate the hinged card structure up and to the rear. The sprlng-

loadad PCBA pivot-lock

automatically locks the Logic

PCBA

Into the vertical

position as shown

In

Figure 2-3.

NOTE

illustrations

used

in this manual

to

depict parts and

locations which

are

common

to

front and

top

loading

versions

will normally

be

of

front loading models.

(7)

Loosen the two retaining screws which secure the Servo PCBA to the

logic

PCBA

(see Figure 2-3).

(8) Swing the Servo PC8A Into Its extended position; engage the locking pin

and

the

PCBA support bracket

(see Figure 2-4).

(9)

Locate and identify the carriage retainer counterweight at the rear

of

the

head

carriage assembly. Figure

2-5

shows the counterweight in Its shipping position.

(10)

Locate and remove the Allen head screw stored in the top

of

the head carriage

assembly adjacent

to

the counterweight.

(11)

Remove the recessed Allen head screw from the counterweight which secures the

head carriage assembly

to

the magnet assembly during shipment. The head

carriage assembly can now

be

movad backward and forward freely.

(12)

Align the two round holes in the counterweight to the two mating holes on top

of

the

head

carriage assembly and insert the Allen head screws removed in Steps

(10)

and

(11).

Figure

2-6

shows the counterweight in

its

operating position. Tighten

each Allen head screw so that the counterweight remains secure during operation

of

the positioner.

CAUTION

IF

THE

UNIT

IS SHIPPED, THE COUNTERWEIGHT MUST

BE USED

TO

SECURE THE CARRIAGE ASSEMBLY.

PERFORM

THE FOLLOWING STEPS

TO

ENSURE THA T

THE COUNTERWEIGHT IS SECURED

IN

ITS SHIPPING

POSITION.

FIGURE

2-5

SHOWS THE COUNTERWEIGHT

IN

ITS SHIPPING POSITION.

2-2

Loading...

Loading...