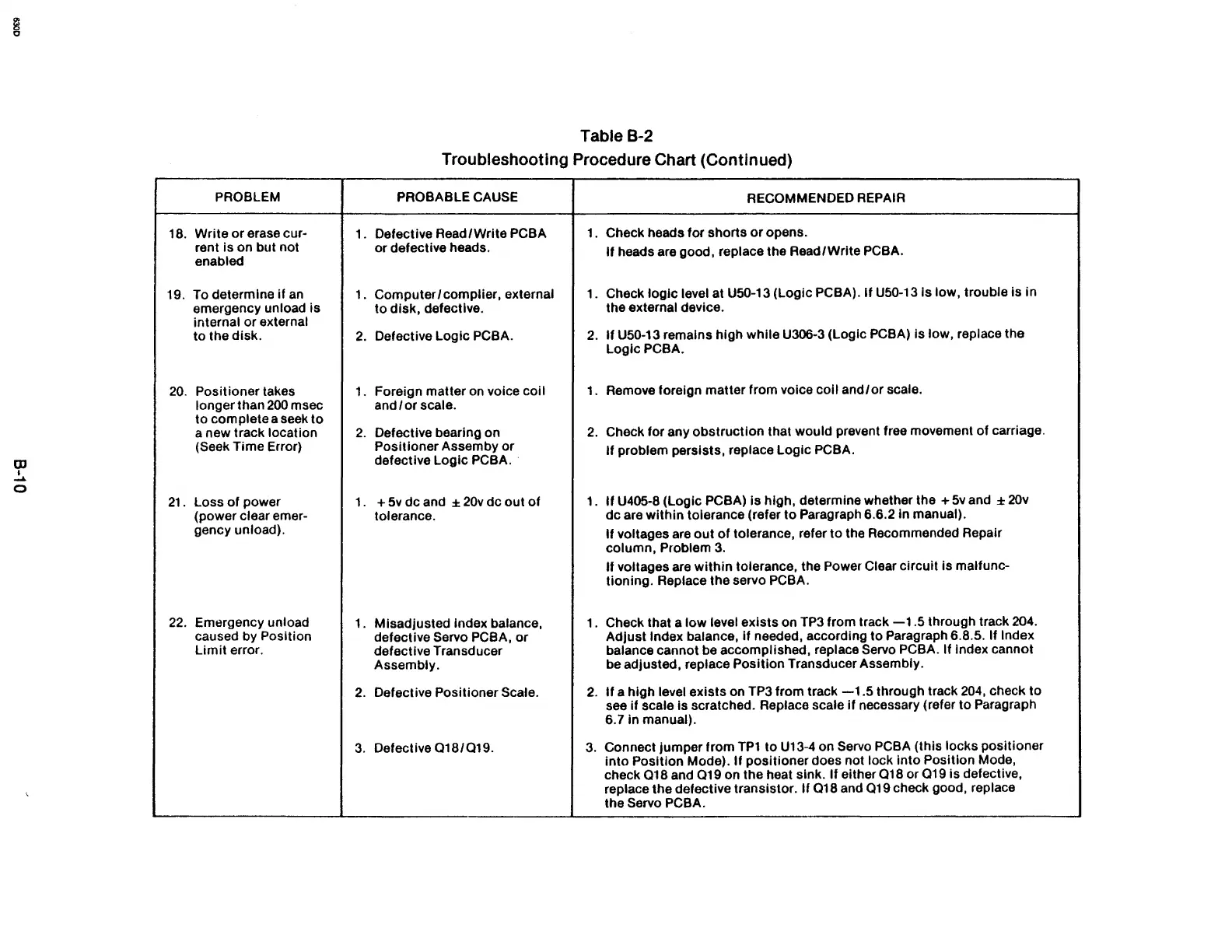

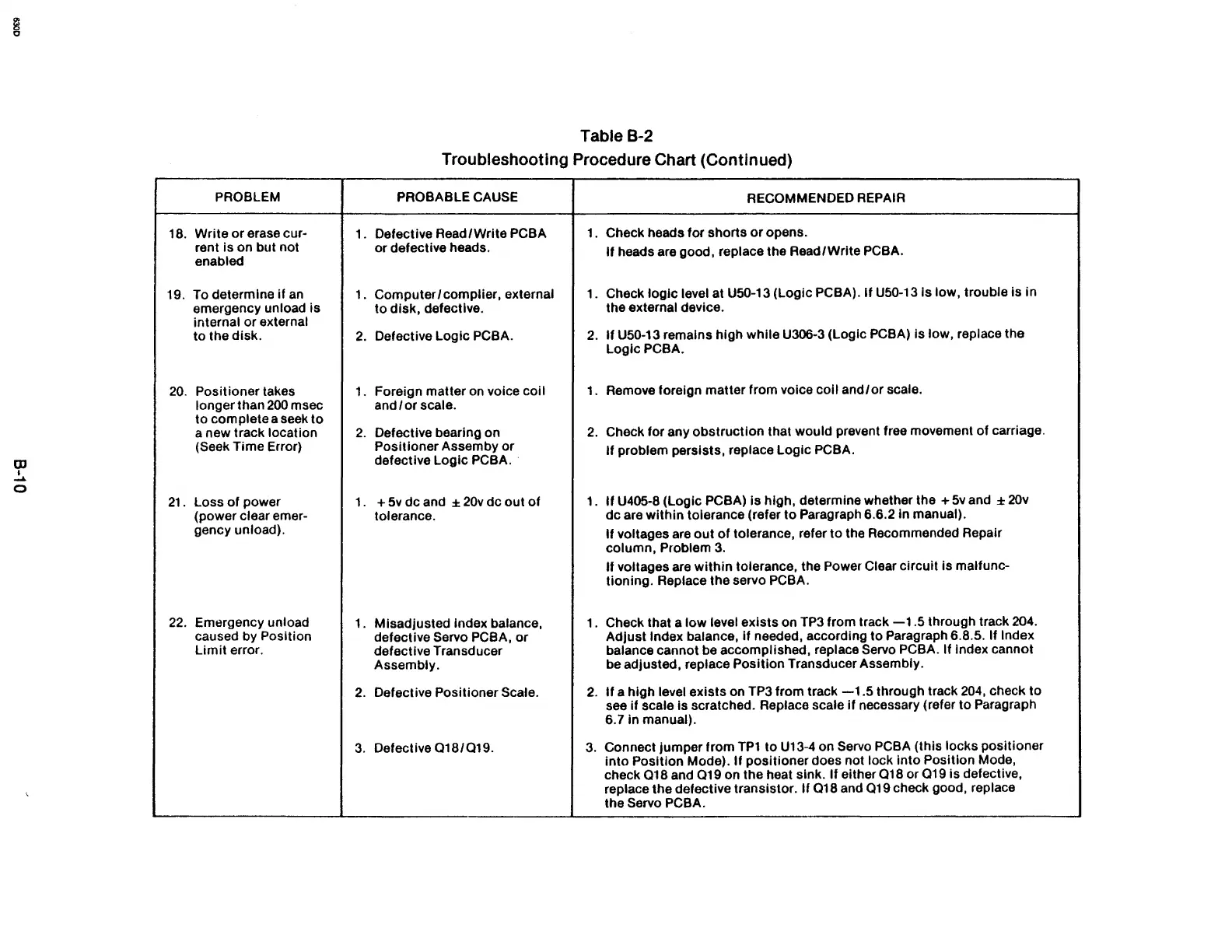

Table B-2

Troubleshooting Procedure Chart (Continued)

PROBLEM PROBABLE CAUSE

RECOMMENDED REPAIR

18.

Write

or

erase cur-

1.

Defective Read/Write PCBA

1.

Check heads for shorts

or

opens.

rent

is

on but not

or defective heads.

If

heads are good, replace the Read/Write PCBA.

enabled

19.

To determine if

an

1.

Computer

1 complier, external

1.

Check logic level at U50-13 (Logic PCBA).

If

USO-13Is low, trouble is in

emergency unload

is

to

disk, defective.

the external device.

internal or

external

to the disk.

2.

Defective Logic PCBA.

2.

If

U50-13 remains high while U306-3 (Logic PCBA) is low, replace the

LoglcPCBA.

20.

Positioner takes

1.

Foreign matter

on

voice coil

1.

Remove foreign matter from voice

coli

and/or

scale.

longer than

200

msec and 1 or scale.

to complete a seek to

a new track location

2.

Defective bearing on

2.

Check for any obstruction that would prevent free movement

of

carriage.

OJ

(Seek Time Error)

Positioner Assemby

or

If

problem persists, replace Logic PCBA.

defective Logic PCBA

..

,

.....

o

21.

Loss

of

power 1. +

5v

dc and ±

20v

dc

out

of

1.

It

U405-8 (Logic PCBA) Is high, determine whether the +

5v

and ±

20v

(power clear emer-

tolerance.

dc are

within

tolerance (refer

to

Paragraph 6.6.2 In manual).

gency unload).

If

voltages are

out

of

tolerance, refer

to

the Recommended Repair

column, Problem

3.

If

voltages are

within

tolerance, the Power Clear circuit Is malfunc-

tioning. Replace the servo

PCBA.

22.

Emergency unload

1. Mlsadjusted

Index balance, 1.

Check that a low level exists on TP3 from track

-l.S

through track 204.

caused

by Position

defective

Servo PCBA,

or

Adjust Index balance,

if

needed, according to Paragraph 6.8.5. If Index

Limit

error.

defective Transducer

balance cannot be accomplished, replace Servo PCBA. If Index cannot

Assembly.

be adjusted, replace Position Transducer Assembly.

2.

Defective Positioner Scale.

2.

If

a high level exists on TP3 from track

-1.5

through track

204,

check to

see if scale

Is scratched. Replace scale

If

necessary (refer to Paragraph

6.7 in manual).

3.

Defective

018/019.

3.

Connect jumper from

TP1

to U13-4 on Servo PCBA (this locks positioner

into

Position Mode).

If

positioner does not lock

into

Position Mode,

check

018

and

019

on the heat sink.

If

either

018

or

019

is

defective,

replace the defective transistor.

If

018

and

019

check good, replace

the Servo PCBA.

Loading...

Loading...