KENR6932 11

Disassembly and Assembly Section

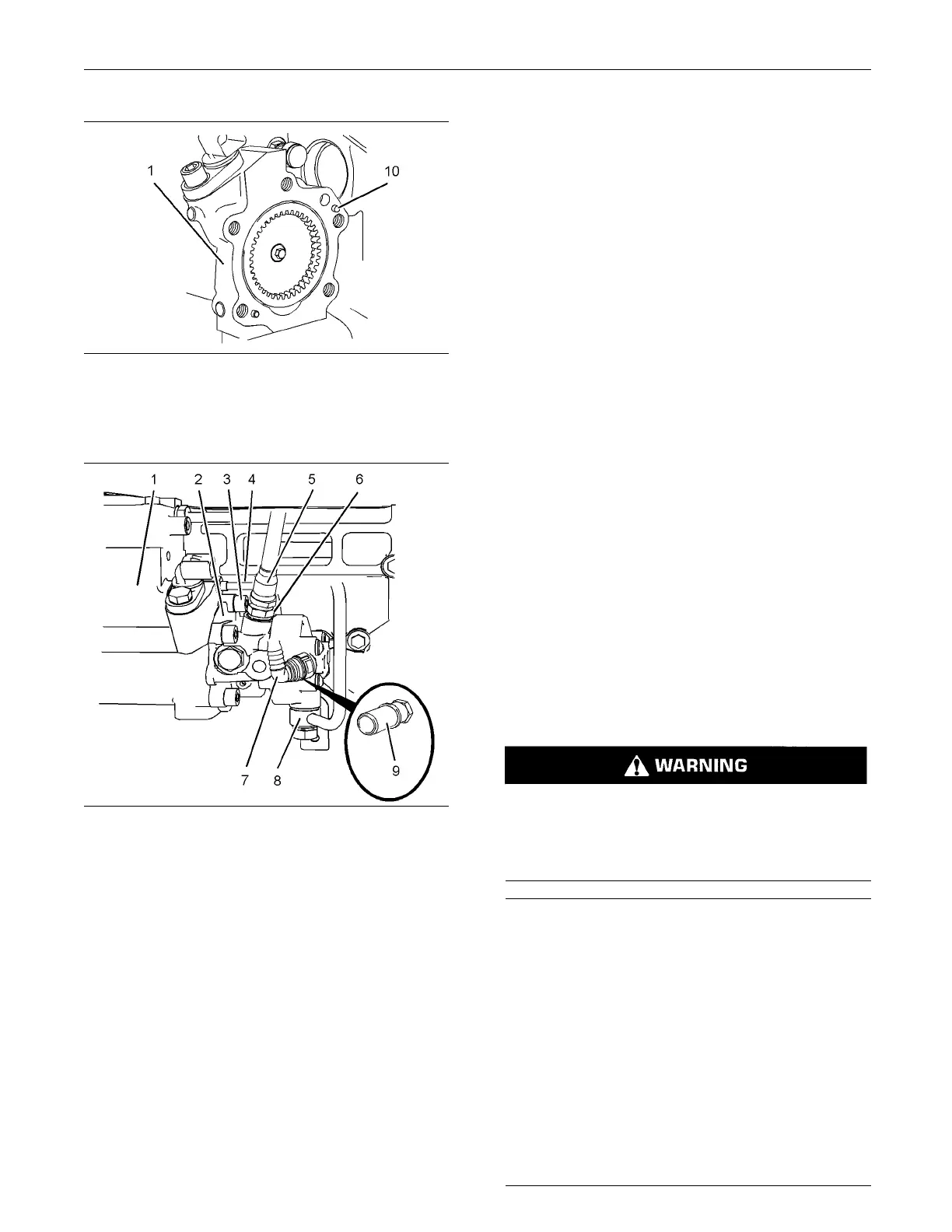

g01335043

Illustration 11

3. Align the holes in fuel transfer pump (2) with

dowels (10) in fuel injection pump (1). Install the

fuel transfer pump to the fuel injection pump.

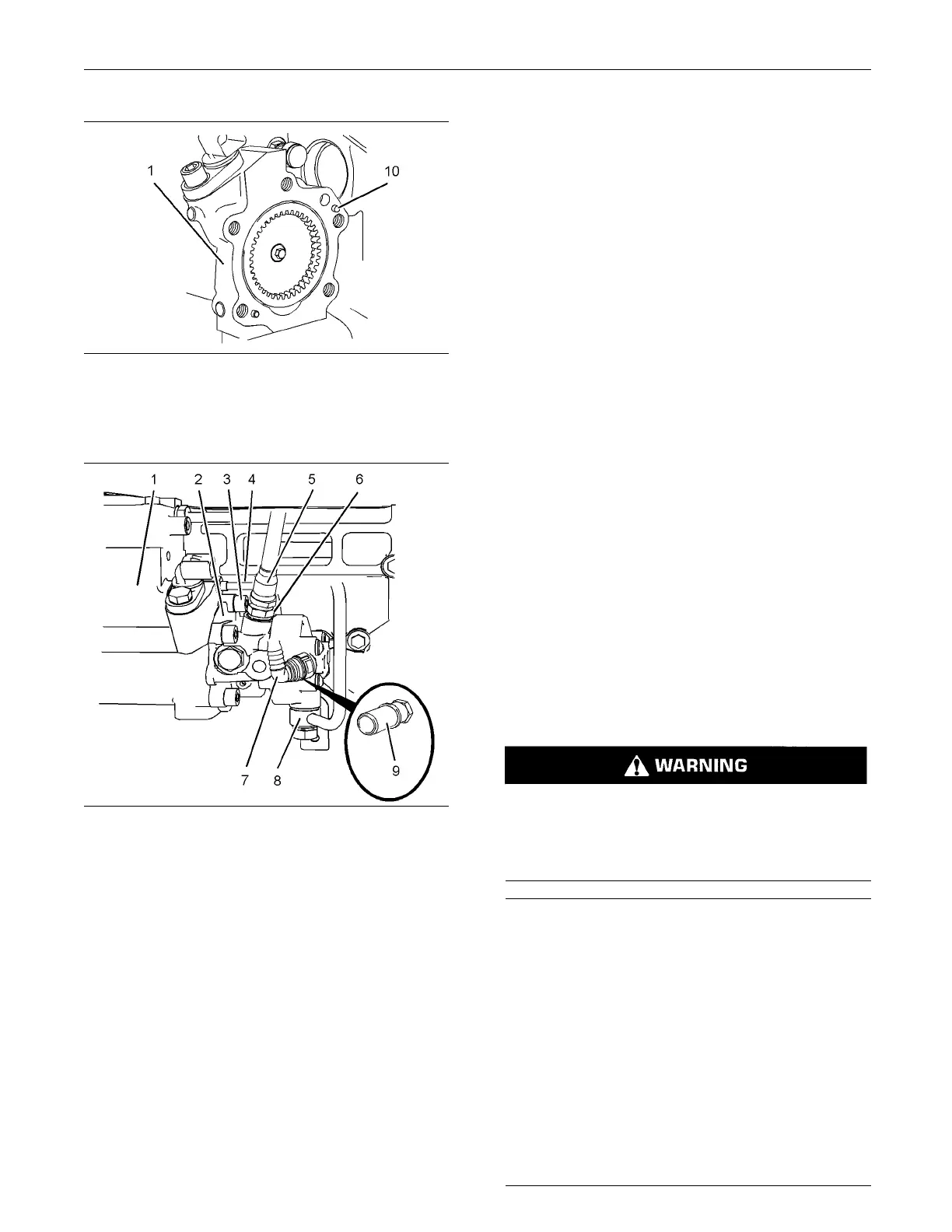

g01334899

Illustration 12

4. Use an allen wrench with a ball end to install the

allen head screws (3). Tighten the allen head

screws to a torque of 30 N·m (22 lb ft).

5. Remove the plugs and the caps from the ports

and tube assemblies.

6. Install tube assembly (4) for the engine oil supply

to fuel injection pump (1). Install new washers to

the banjo bolt for oil supply tube assembly. Install

the banjo bolt to the cylinder block. Tighten both

connectors to a torque of 15 N·m (11 lb ft).

7. Install tube assembly (8) for the fuel return to fuel

transfer pump (2) and to the cylinder head. Tighten

both banjo bolts to a torque of 21 N·m (15 lb ft).

8. Install a new O-ring seal to connector (6). Install

connector (6) to fuel transfer pump (2). Tighten

theconnectortotorqueof15N·m(11lbft).

9. If necessary, install a new O-ring seal to connector

(9) and install

connector (9) to fuel transfer pump

(2). Tighten the connector to torque of 15 N·m

(11 lb ft).

10. Connect plastic tube assembly (5) to the outlet of

fuel transfer pump (2).

11. Install plastic tube assembly (7) to fuel transfer

pump (2).

12. Restore the fuel supply.

13. Remove the ai

r from the fuel system. Refer to

System Operation, Testing and Adjusting, “Fuel

System - P rime”.

i02654510

Fuel M anifold ( Rail) - Remove

and Install

Removal Procedure

Start By:

a. Remove the fuel injection lines. Refer to

Disassembly and Assembly, “Fuel Injection Lines

- Remove”.

b. If necessary, remove the fuel pressure sensor.

Refer to Disassembly and Assembly, “Fuel

Pressure Sensor - Remove and Install”.

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fu-

el spray may cause a fire hazard. Failure to fol-

low these inspection, maintenance and service in-

structions may cause personal injury or death.

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authoris

ed personnel that have the correct train-

ing.

Before be

gining ANY work on the fuel system, re-

fer to Operation and Maintenance Manual, “Gen-

eral Hazard Information and High Pressure Fuel

Lines” fo

r safety information.

Refer to System Operation, Testing and Adjusting,

“Cleanli

ness of Fuel S ystem Components” for de-

tailed information on the sta ndards of cleanliness

that must be observed during ALL work on the fu-

el syste

m.

Loading...

Loading...