KENR6932 73

Disassembly and Assembly Section

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

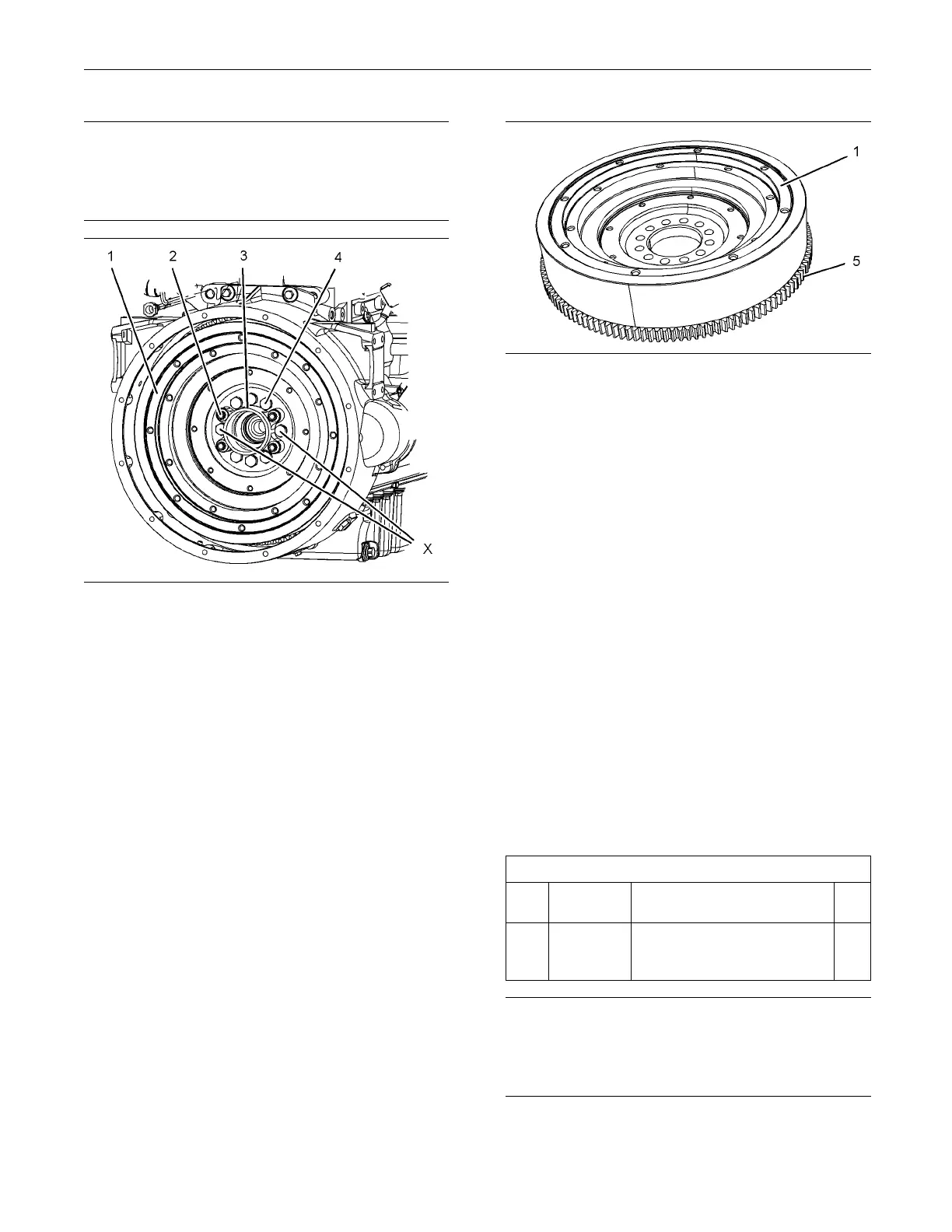

g01336668

Illustration 127

Typical exam p le

1. Remove bolts from position (X) on flywheel (1).

2. Install Tooling (A) in position (X) on flywheel (1).

3. Attach a suitable lifting device to flywheel (1).

Support the weight of the flywheel. The flywheel

can weigh 70.6 kg (155 lb).

4. If necessary, remove bolts (2) that secure the

housing for pilot bearing (3) to flywheel (1).

Remove the housing for pilot bearing (3).

5. Remove remaining bolts (4).

6. Use the lifting device to remove the flywheel from

the engine.

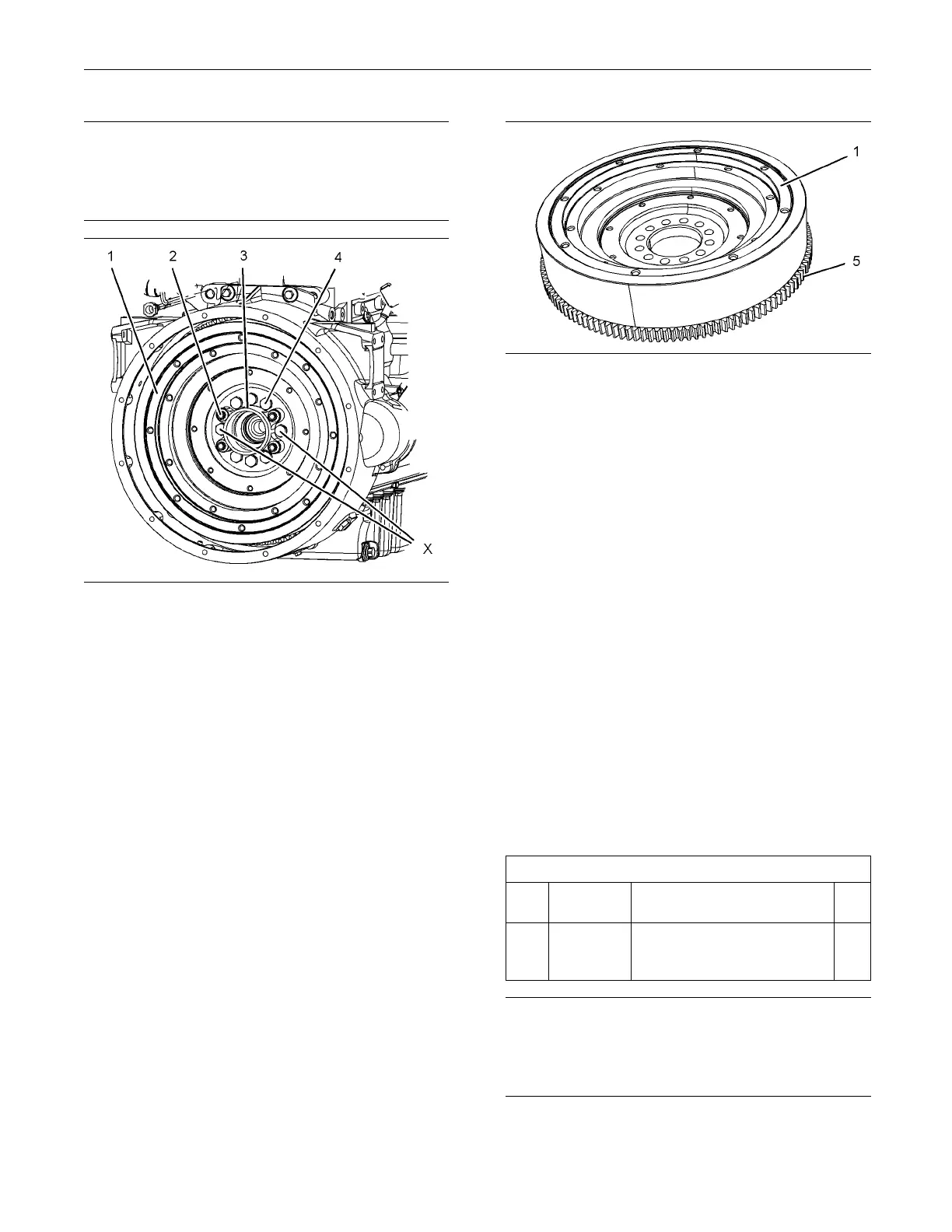

g01336669

Illustration 128

Typical example

7. Inspect flywheel (1) and ring gear (5) for wear

or damage. Replace any worn components or

damaged components.

8. To r e mo v e flywheel ring gear (5), follow steps 8.a

and 8.b.

a. Place the flywheel assembly on a suitable

support.

b. Use a hammer and a punch in order to remove

ring gear (5) from flywheel (1).

Note: Identify the orientation of the teeth on the

flywheel ring gear.

i02654492

Flywheel - Ins tall

Installat

ion Procedure

Table 24

Required Tools

Tool

Part

Number Part Description Qty

A

-

Guide Stud

(1/2 inch - 20 UNF by 4

inch)

2

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Loading...

Loading...