154 KENR6932

Disassembly a nd Assembly Section

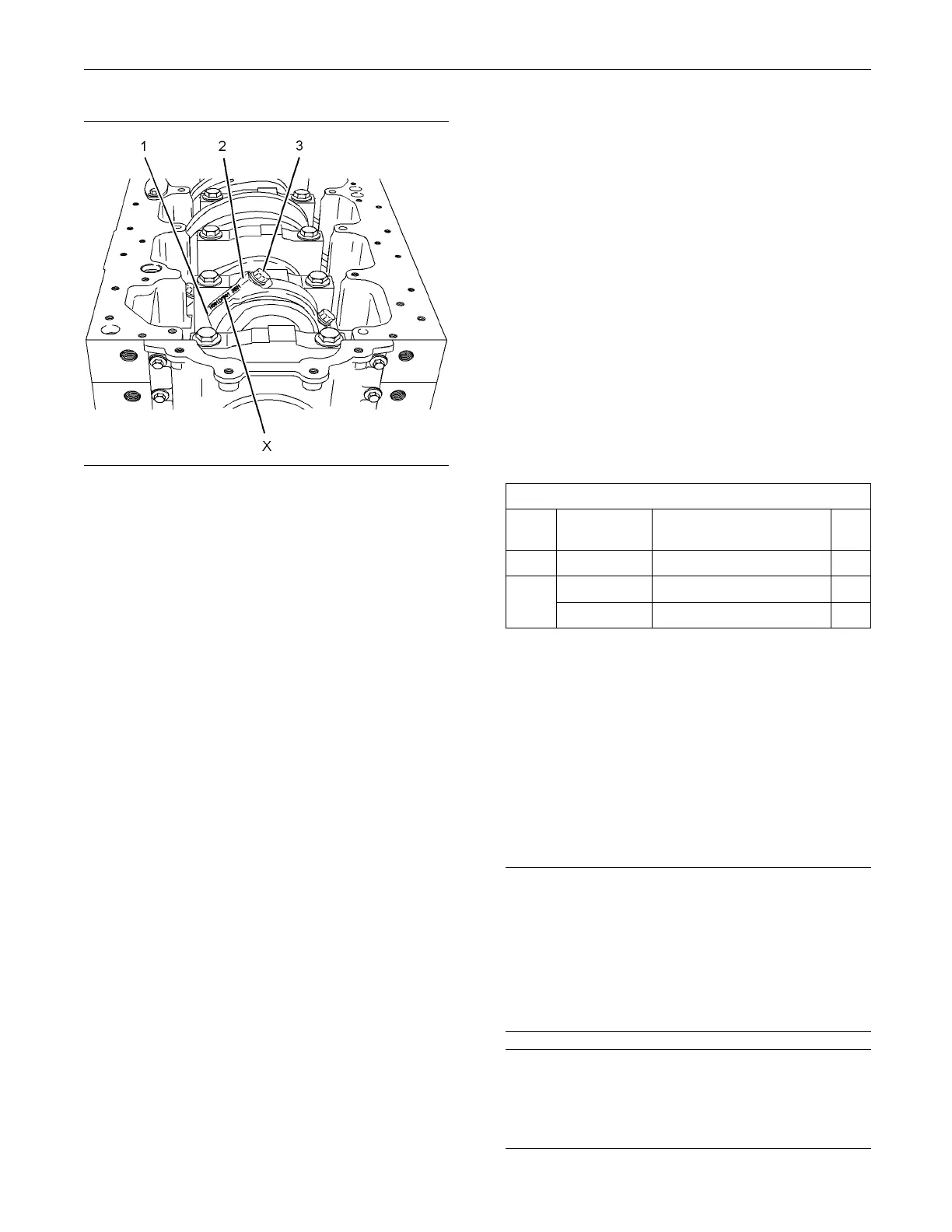

g01341291

Illustration 308

8. Install connecting rod cap (2) to connecting rod

(5).

Note: Ensure that etched number (X) on connecting

rod cap (2) matches etched number (X) on

connecting rod (5). Ensure the correct orientation of

the connecting rod cap. The locating tab for the upper

bearing shell and the lower bearing shell should be

on the same side.

9. Install new bolts (1) to the connecting rod. Tighten

theboltsevenlytoatorqueof18N·m(13lbft).

Note: Do not reuse the old bolts in order to secure

the connecting rod cap.

10. Tighten the bolts evenly to a torque of 70 N·m

(52 lb ft).

11. Turn the bolts through an additional 120 degrees.

UseTooling(B)toachievethecorrectfinal torque.

12. Ensure that the installed connecting rod assembly

has tactile side play. Rotate the crankshaft in order

to ensure that there is no binding.

13. Repeat Steps 2 through 12 for the remaining

connecting rod bearings.

Note: If all connecting rod bearings require

replacement the procedure can be carried out on

two cylinders at the same time. The procedure can

be carried out on the following pairs of cylinders. 1

with6,2with5,and3with4.Ensure that both

pairs of the connecting rod bearings are installed

before changing from one pair of cylinders to

another pair of cylinders.. Refer to Disassembly

and Assembly, “Connecting Rod Bearings - Install”.

14. If the glow plugs were removed, install the glow

plugs. Ref to Di

sassembly and Assembly, “Glow

Plugs - Remove and Install”

End By:

a. Install the engine oil pump. Refer to Disassembly

and Assembly,

“Engine Oil Pump - Install”.

i02654465

Crankshaft Main Bearings -

Remove and Ins tall

(Crankshaft in p osition)

Removal Procedure

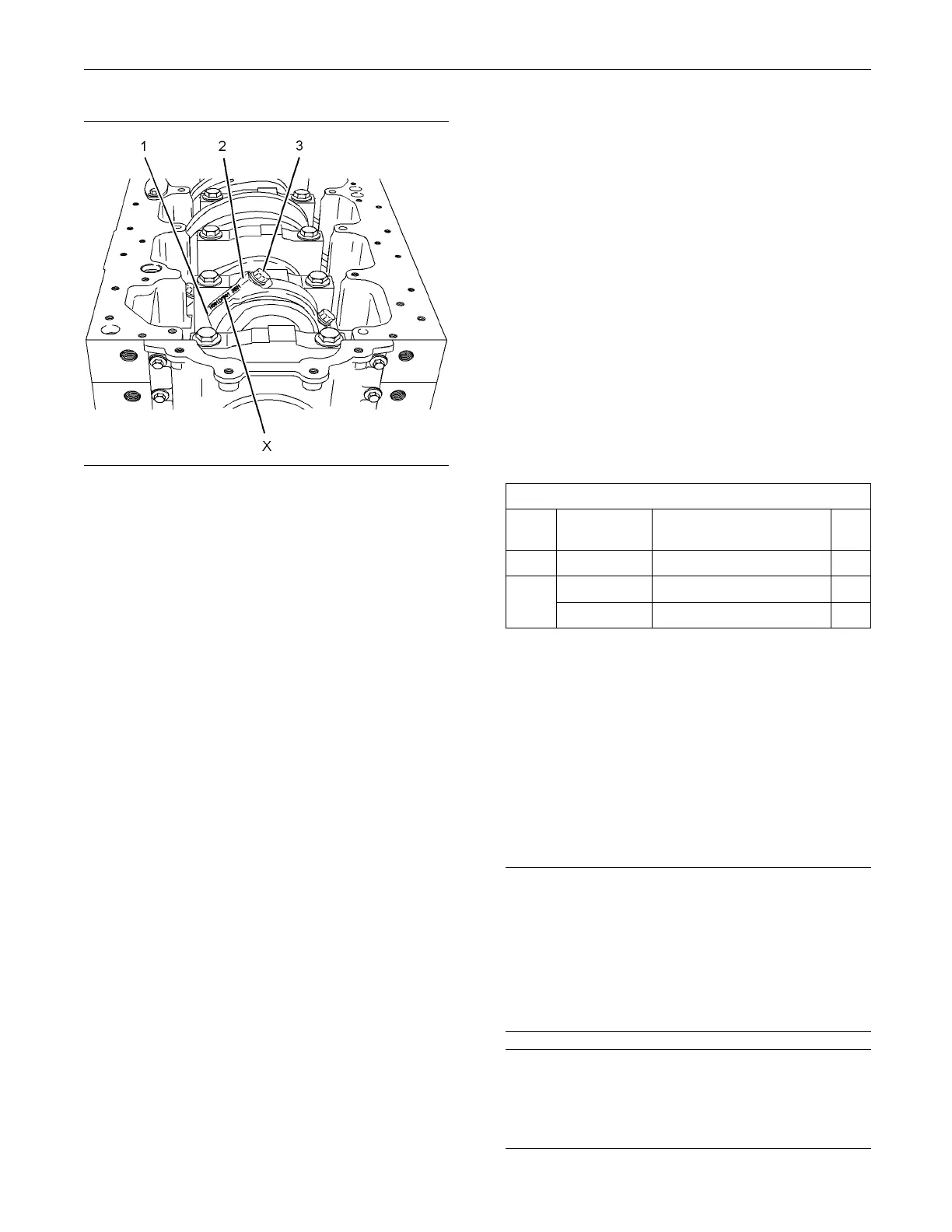

Table 74

Required Tools

Tool

Part

Number

Part Name Qty

A

1

21825576

Crankshaft Turning Tool

1

27610291

Barring Device Housing 1

A

2

27610289

Gear 1

Start By:

a. Remove the en

gine oil pump. Refer to

Disassembly and Assembly, “Engine Oil Pump

- Remove”.

b. Remove the crankshaft rear seal. Refer to

Disassembly and Assembly, “Crankshaft Rear

Seal - Remov

e”.

Note: EitherTooling(A)canbeused.UsetheTooling

that is most

suitable.

NOTICE

This procedure must only be used to remove and in-

stall the main bearing shells with the crankshaft in po-

sition.

The removal procedure and the installation procedure

must be com

pleted for each pair of main bearing shells

before the next pair of main bearing shells are re-

moved.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Loading...

Loading...