6 KENR6932

Disassembly a nd Assembly Section

Installation Procedure (Manual

Priming Pump)

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorised personnel that have the correct train-

ing.

Before begining ANY work on the fuel system, re-

fer to Operation and Maintenance Manual, “Gen-

eral Hazard Information and High Pressure Fuel

Lines” for safety information.

Refer to System Operation, Testing and Adjusting,

“Cleanliness of Fuel System Components” for de-

tailed information on the standards of cleanliness

that must be obs erved during ALL work on the fu-

el system.

1. Ensure that fuel priming pump (4) is clean and

free from wear or damage. If necessary, replace

the fuel priming pump.

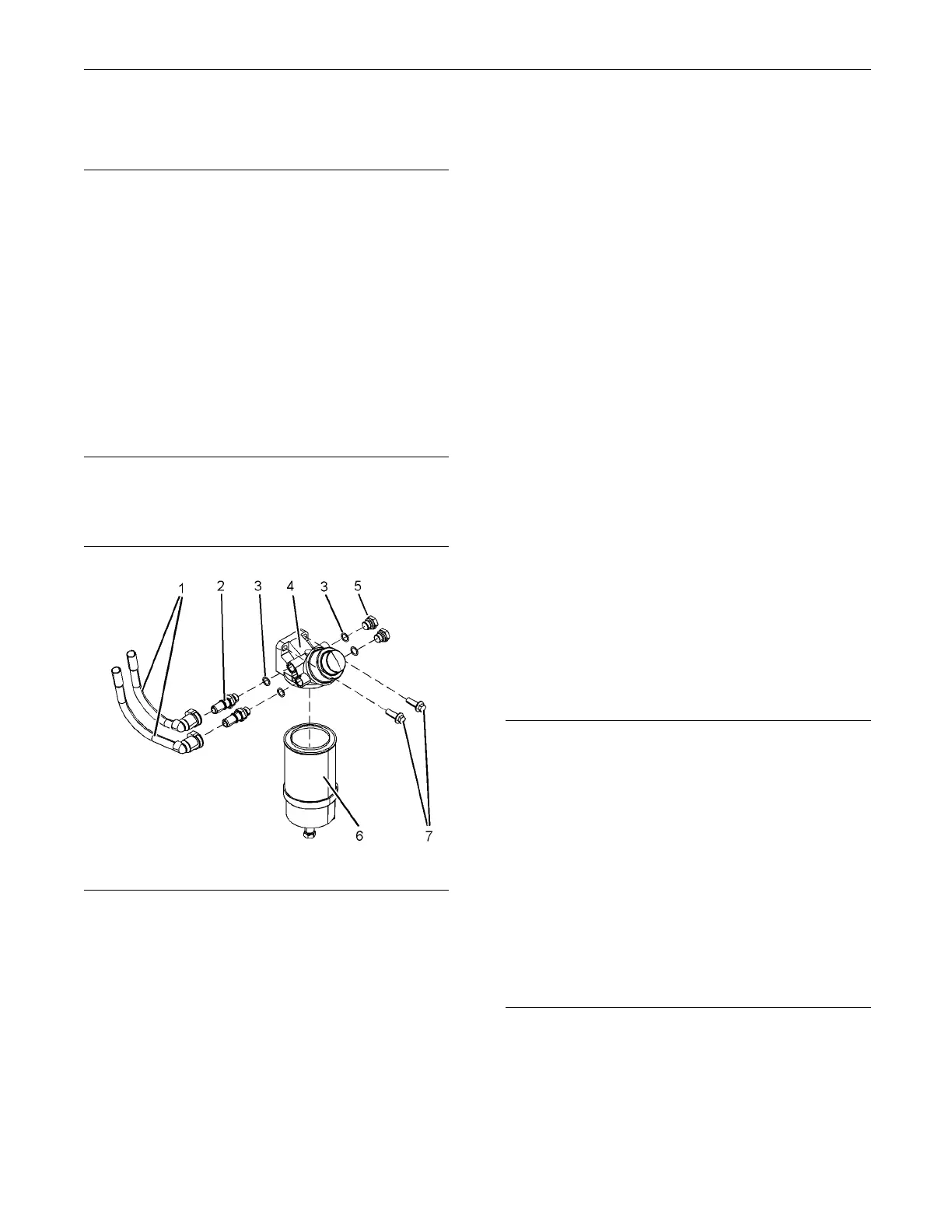

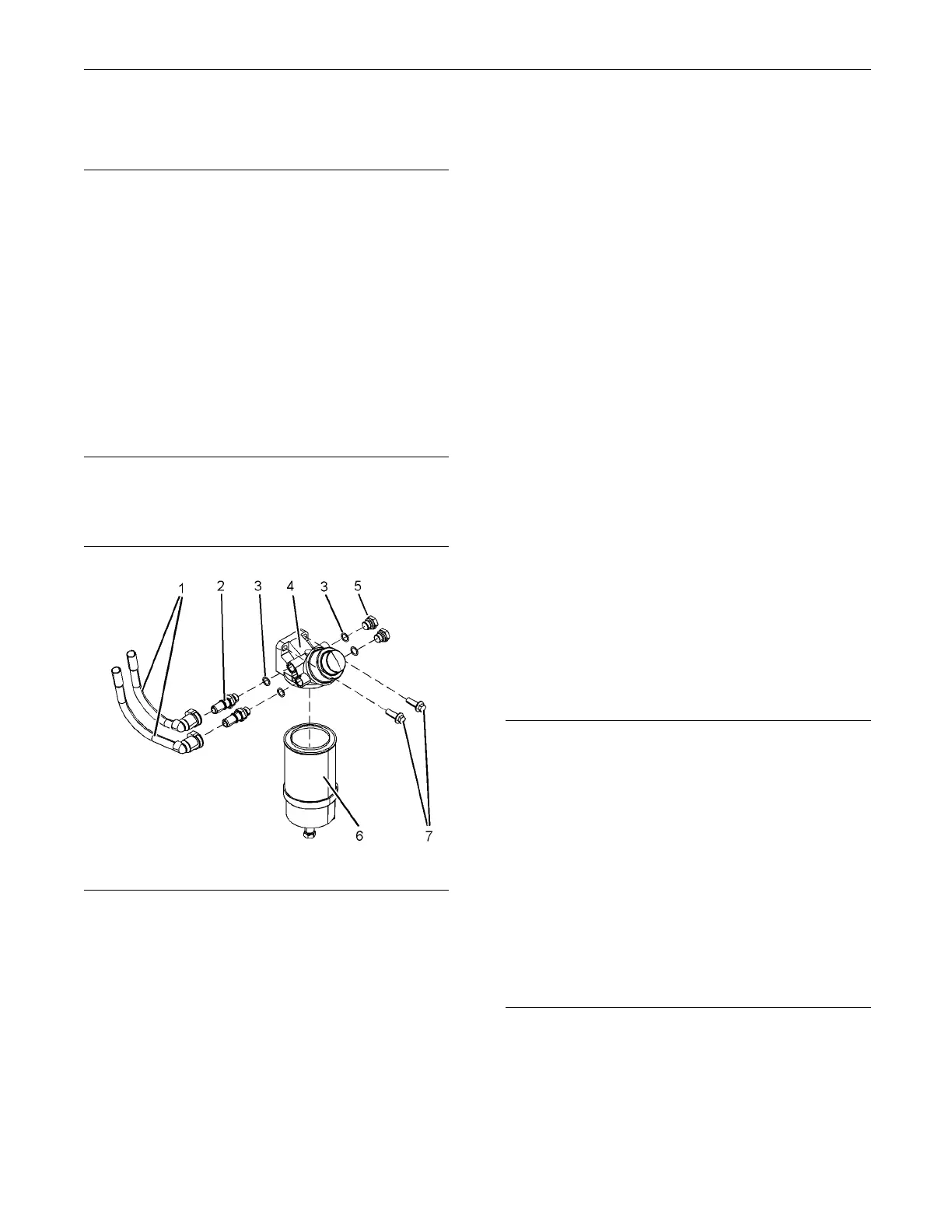

g01334872

Illustration 2

Typical exam p le

2. If necessary, follow Steps 2.a through 2.d in order

to assemble fuel priming pump (4).

a. Install new O-ring seals (3) to connectors (2)

andtoplugs(5).

b. Install connectors (2) to fuel priming pump (4).

c. Install plugs (5) to fuel priming pump (4).

d. Tighten the plugs and the connectors to a

torque of 20 N·m (14 lb ft).

3. Position fuel priming pump (4) on the mounting

bracket. Insta

ll bolts (7) to the fuel priming pump .

Tighten the bolts to a torque of 44 N·m (32 lb ft).

4. Remove the plu

gs from the plastic tube

assemblies. Remove the caps from the

connectors.

5. Connect plastic tube assemblies (1) to connectors

(2).

Note: Ensure that the plastic tube assemblies are

installed in the original positions.

6. Install a new primary filter (6) to fuel priming pump

(4). Refer to Operation and Maintenance Manual,

“Fuel System

Primary Filter (Water Seperator)

Element - Replace”.

7. Restore the f

uel supply.

8. Prime the fuel system. Refer to Operation and

Maintenanc

e Manual, “Fuel System - Prime”.

i02654355

Fuel Prim ing Pump - Remo ve

and Install

(Electrical Primin g Pump )

Removal Procedure

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorised personnel that have the correct train-

ing.

Before begining ANY work on the fuel system, re-

fer to Operation and Maintenance Manual, “Gen-

eral Hazard Information and High Pressure Fuel

Lines” for safety information.

Refer to System Operation, Testing and Adjusting,

“Cleanliness of Fuel System Components” for de-

tailed information on the sta ndards of cleanliness

that must be observed during ALL work on the fu-

el system.

1. Isolate the fuel supply.

Loading...

Loading...