KENR6932 17

Disassembly and Assembly Section

10. Loosely connect the nuts at both ends of fuel

injection line

(2), to electronic unit injector (1) and

to the appropriate port in fuel manifold (4). Ensure

that the ends of the fuel injection line are correctly

seated in the e

lectronic unit injector and in the

fuel manifold.

11. Use Tooling (

A) to tighten the nuts on fuel injection

line(2)toatorqueof30N·m(22lbft).Ensurethat

the dust seal is seated correctly against seal (5).

12. Follow Steps 8 through 11 in order to install the

remaining fuel injection lines.

13. Install new clamps (3) to the fuel injection lines.

Ensure that the clamps are fully closed in order to

retain the fu

el injection lines.

Note: Ensure that fuel injection lines do not contact

any other en

gine component.

14. Restore the fuel supply.

15. Restore the electrical supply.

16. If the engin

e was equipped with a cover over the

fuel system this will need to be installed.

17. Remove the a

ir from the fuel system. Refer

to Operations and Maintenance Manual, “Fuel

System - Prime”.

i02654505

Fuel Injection Pu mp - Remove

Removal Procedure

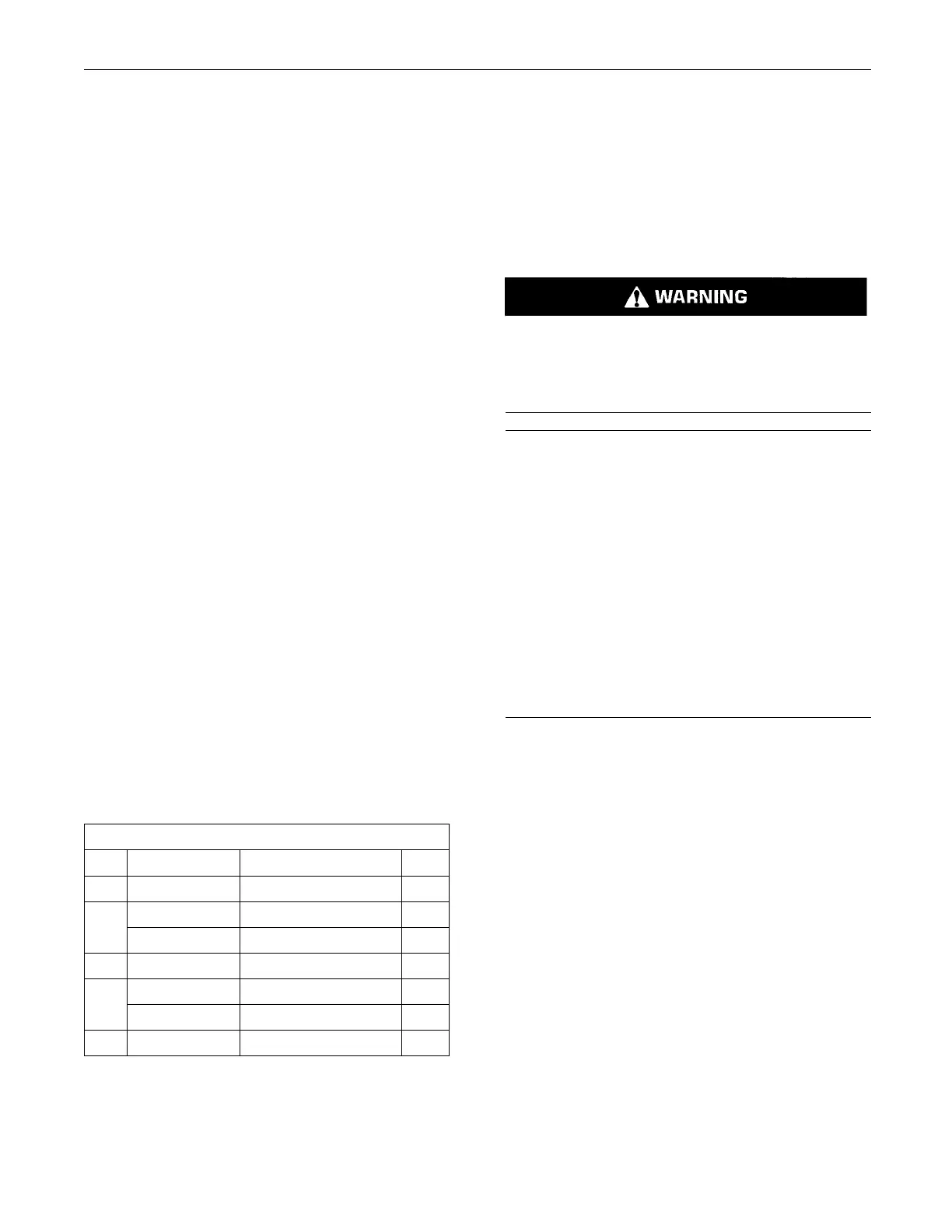

Table 3

Required Tools

Tool Part Number Part Name Qty

A

21825576

Crankshaft Turning Tool 1

27610291

Barring De

vice Housing

1

A

27610289

Gear

1

B 27610212

Camshaft Timing Pin

1

27610286

Crankshaft Timing Pin

1

C

27610287

Adapter 1

D

-

Cap 2

Start By:

a. If necess

ary, remove the fuel filter base. Refer to

Disassembly and Assembly, “Fuel Filter Base -

Remove and Install”.

b. If necessary, remove the fuel priming pump. Refer

to Disassembly

and Assembly, “Fuel Priming

Pump - Remove”.

c. Remove the fro

nt cover. Refer to Disassembly

and Assembly, “Front Cover - Remove and Install”.

Note: Either T

ooling (A) can be used. Use the Tooling

that is most suitable.

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fu-

el spray may c

ause a fire hazard. Failure to fol-

low these inspection, maintenance and service in-

structions may cause personal injury or death.

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorised personnel that have the correct train-

ing.

Before begining ANY work on the fuel system, re-

fer to Operation and Maintenance Manual, “Gen-

eral Hazard Information and High Pressure Fuel

Lines” for safety information.

Refer to System Operation, Testing and Adjusting,

“Cleanliness of Fuel System Components” for de-

tailed information on the sta ndards of cleanliness

that must be observed during ALL work on the fu-

el system.

1. Isolate the fuel supply.

2. Isolate the electrical supply.

3. Use Tooling (A) in order to rotate the crankshaft

so that number one piston is at top dead center

on the compression stroke. Refer to System

Operation, Testing and Adjusting, “Finding Top

Centre Position for No.1 Piston”.

4. Use Tooling (B) in order to lock the camshaft in

the correct position. Use Tooling (C) in order to

lock the crankshaft in the correct position. Refer to

Disassembly and Assembly, “Gear Group (Front)

- Remove” for the correct procedure.

5. Remove the backlash from the fuel pump gear.

Lock the fuel injection pump in the correct

position and remove the fuel pump gear. Refer to

Disassembly and Assembly, “Fuel Pump Gear -

Remove and Install” for the correct procedure.

Loading...

Loading...