KENR6932 183

Disassembly and Assembly Section

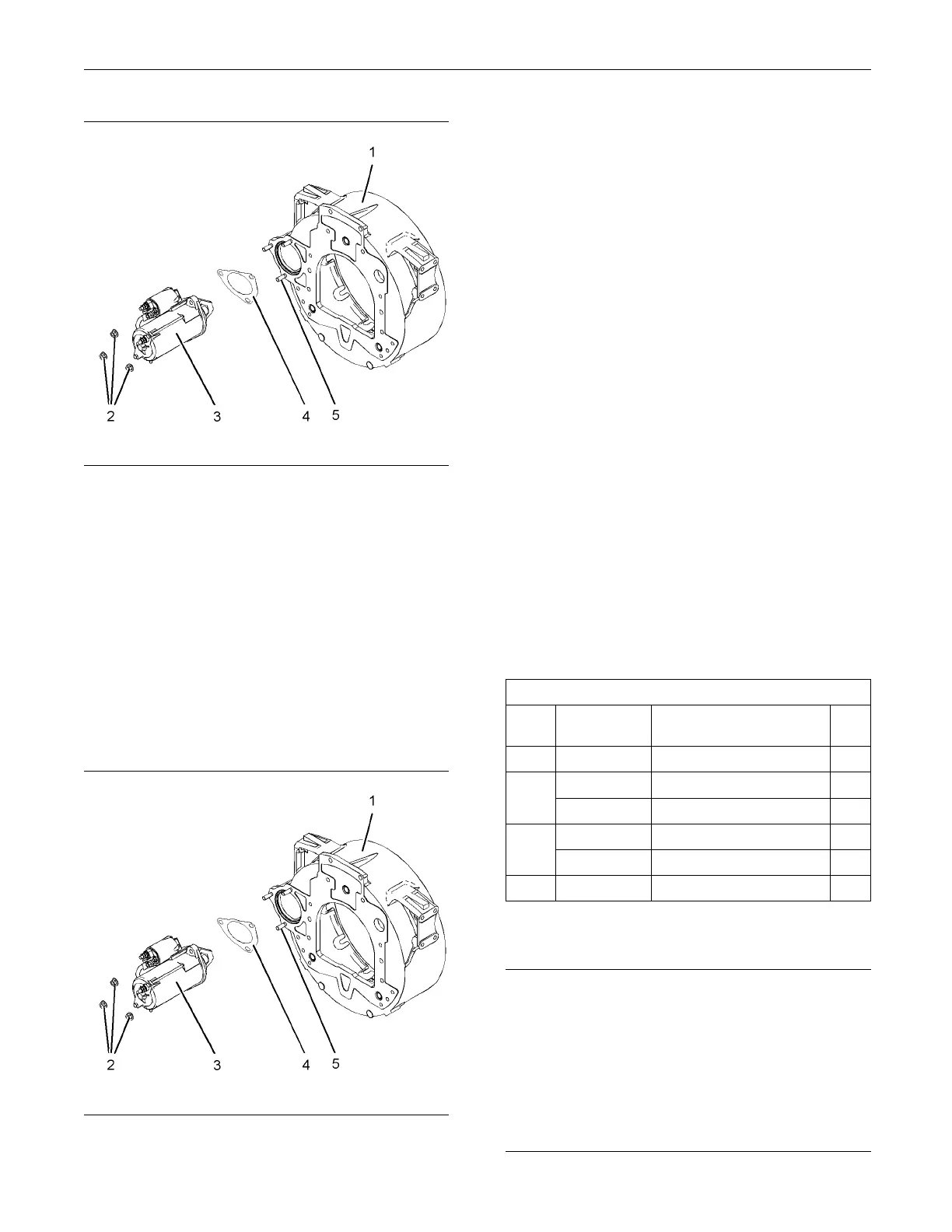

g01342054

Illustration 370

Typical exam p le

3. Disconnect the harness assembly from the electric

starting motor and the solenoid.

4. Remove nuts (2) for electric starting motor (3).

5. Remove electric starting motor (3).

6. If a joint is installed, remove joint (4).

7. If necessary, remove studs (5) from flywheel

housing (1).

Installation Procedure

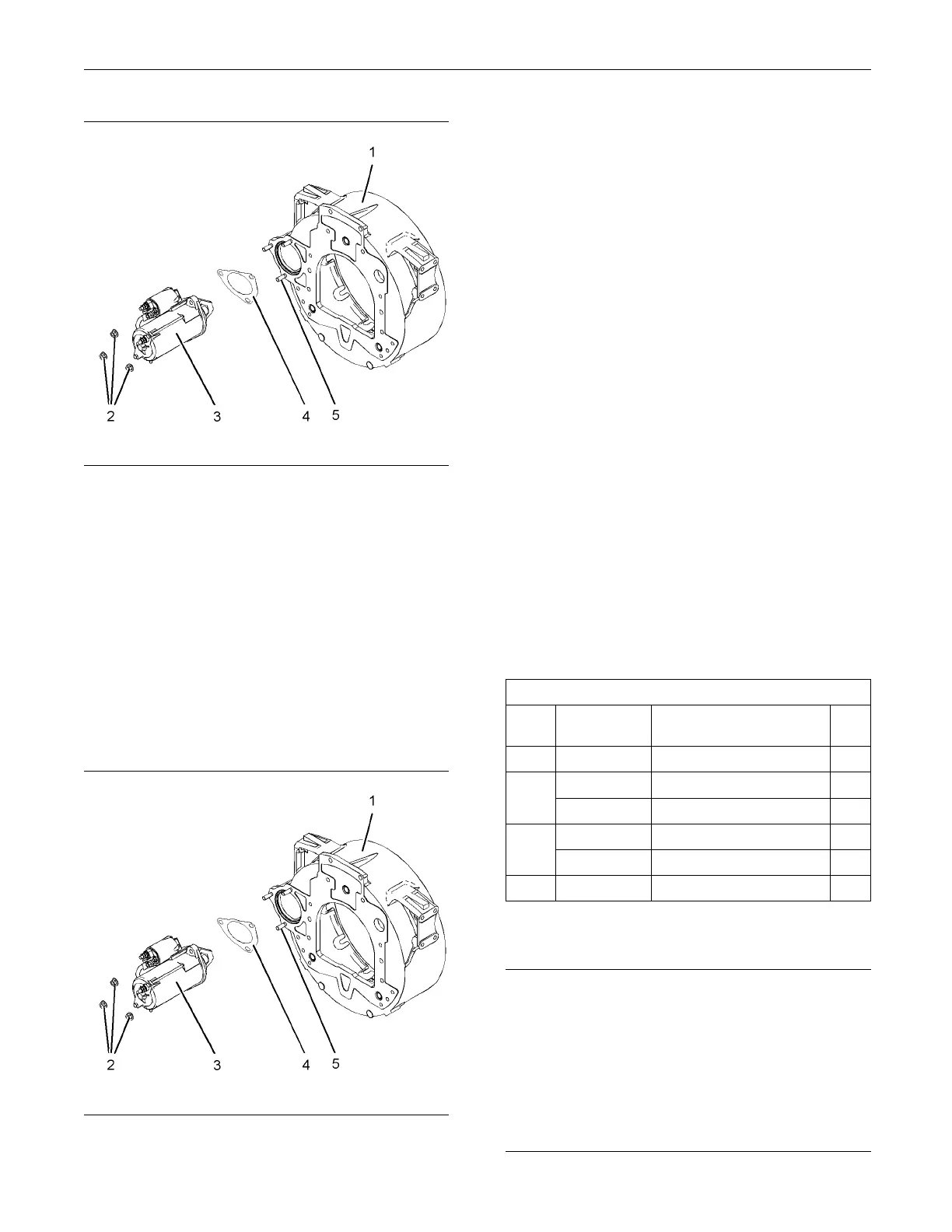

g01342054

Illustration 371

Typical exam p le

1. If necessary, install studs (5) into flywheel housing

(1).

2. If necessary, install a new joint (4) onto the studs

in flywheel hou

sing (1).

3. Position electric starting motor (3) onto the studs

in flywheel hou

sing (1).

4. Install nuts (2).

TightenM10nutstoatorqueof44±11N·m

(32±8lbft).

Tighten M12 nuts to a torque of 78 ± 19.5 N·m

(57 ± 14 lb ft).

5. Connect the harness assembly to the electric

starting motor and the solenoid.

6. Connect the battery.

i02654446

Air C om pressor - Remove and

Install

Removal Procedure

Table 83

Required Tools

Tool

Part

Number

Part Name Qty

A

1

21825576

Crankshaft Turning Tool

1

27610291

Barring Device Housing 1

A

2

27610289

Gear 1

27610286

Crankshaft Timing Pin 1

B

27610287

Adapter 1

C

-

Puller (Three Leg)

1

Note: EitherTooling(A)canbeused.UsetheTooling

that is most suitable.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Loading...

Loading...