178 KENR6932

Disassembly a nd Assembly Section

g01341877

Illustrat

ion 359

Typical exam p le

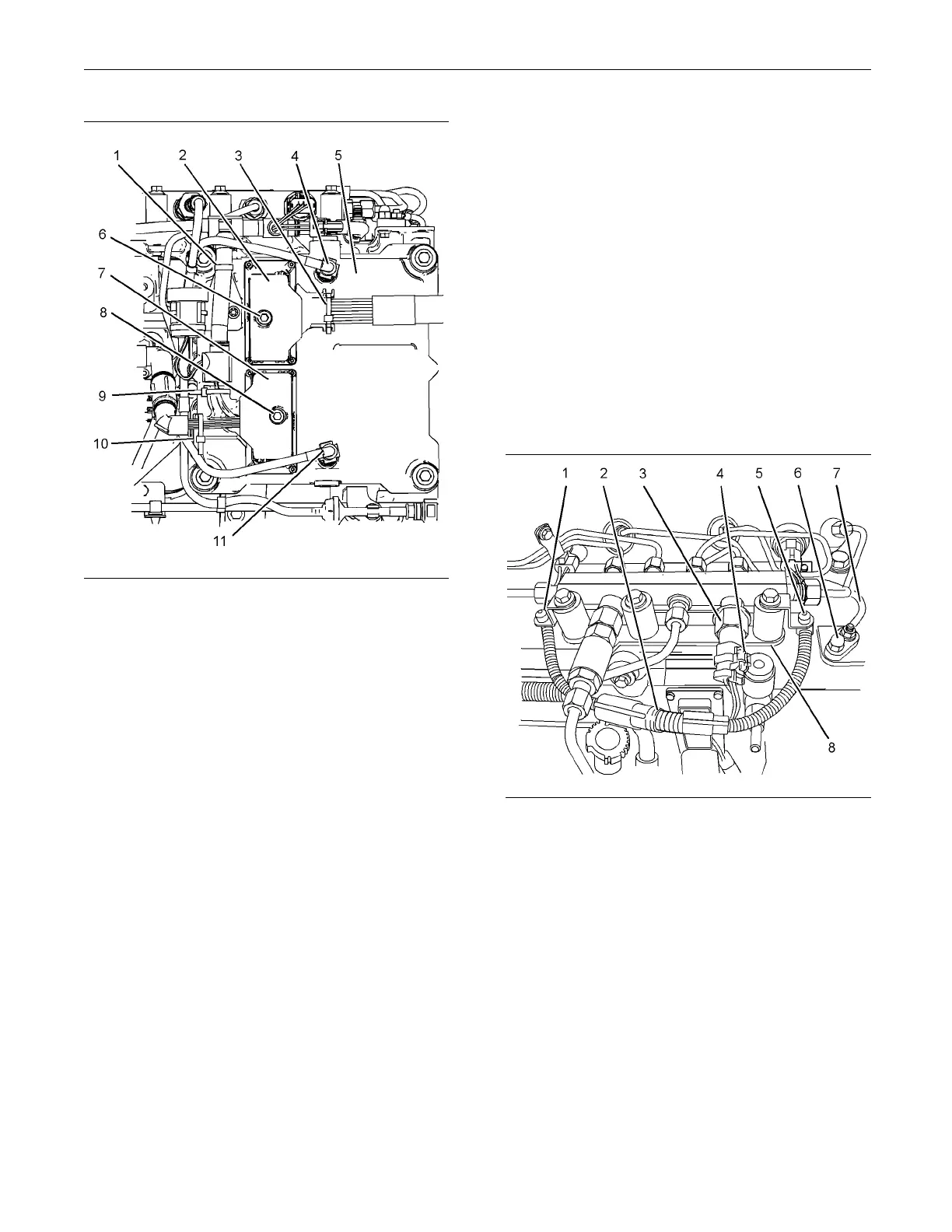

6. Remove the plugs from plastic tube assemblies

(4) and (11). If necessary, remove the caps from

the conne

ctors in the electronic control module.

Connect plastic tube assemblies (4) and (11).

7. Connect e

ngine wiring harness (7) to electronic

control module (5). Tighten the fastener (8) to a

torque of 5 N·m (3 lb ft).

Note: Caremustbetakeninordertoavoiddamageto

the connector pins during installation of the harness.

8. Position the assembly of the engine wiring harness

onto brackets (14) and (16). Use new cable straps

(1), (9)

and (10) in order to secure the harness

assembly to the brackets.

9. Connect

OEM wiring harness (2) to electronic

control module (5). Tighten fastener ( 6) to a torque

of 5 N·m (3 lb ft).

Note: Caremustbetakeninordertoavoiddamageto

the connector pins during installation of the harness.

10. Use a new cable strap (3) in order to secure the

harness assembly.

11. Restore the fuel supply to the engine.

12. Restor

e the electrical supply to the engine.

13. Remove the air from the fuel system. Refer to

Operation and M

aintenance Manual, “Fuel System

- Prime”.

i02654477

ECM Moun ting Bracket -

Remove and Ins tall

Removal Procedure

Start By:

a. Remove the electronic control module. Refer to

Disassembly

and Assembly, “Electronic Control

Module - Remove and Install”.

g01342045

Illustration 360

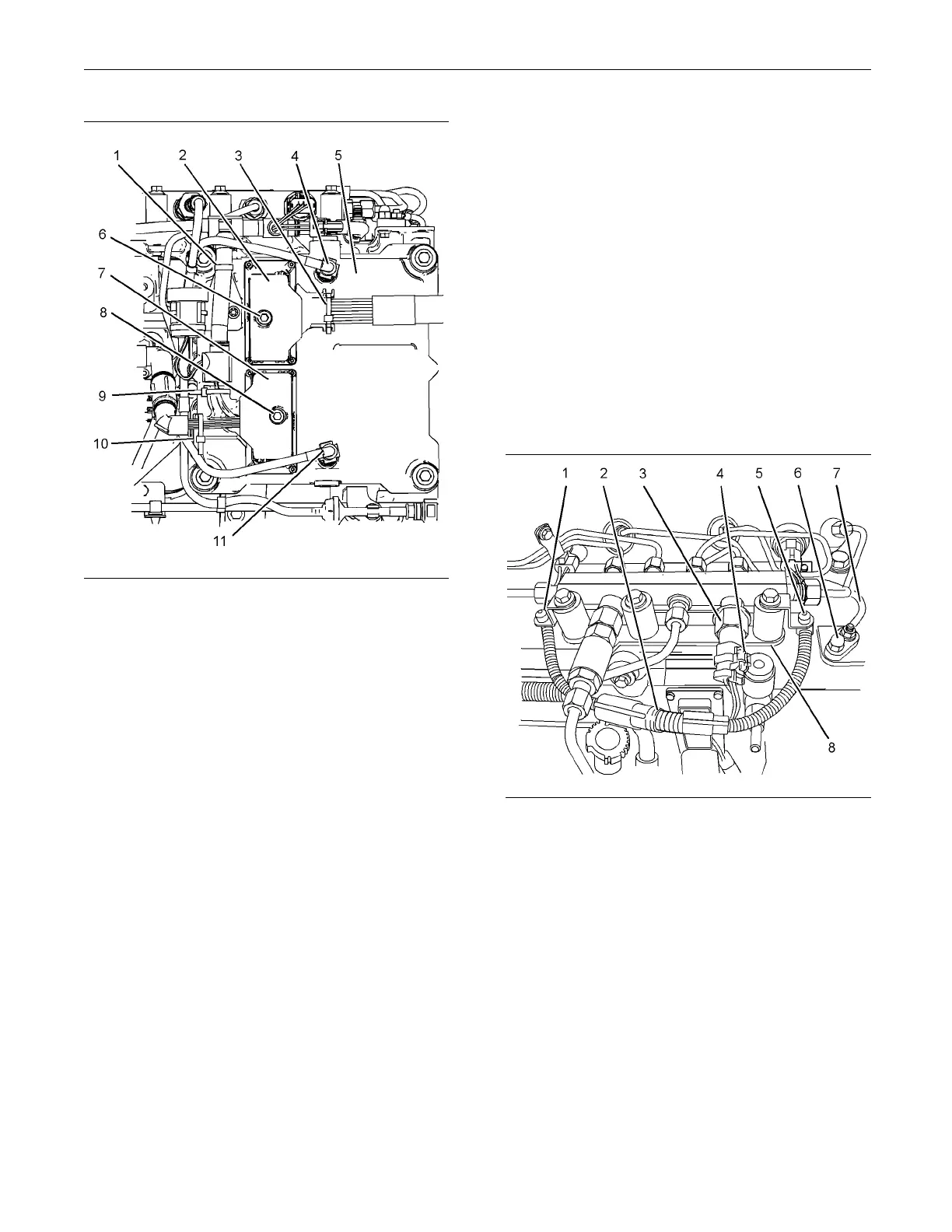

1. Follow Steps 1.a through 1.c in order to disconnect

engine wiring harness (2) .

a. Slide locking tab (4) into the unlocked position.

b. Disconnect harness assembly (2) from fuel

pressure sensor (3).

c. Cut cable straps (1) and (5). Position harness

assembly (2) so that the harness assembly is

clear of mounting bracket (8).

2. Disconnect wire (7) for the glow plugs. Remove

terminal insulator (6) from mounting bracket (8).

Refer to Disassembly and Assembly, “Glow Plugs

- Remove and Install” for the correct procedure.

Loading...

Loading...