78 KENR6932

Disassembly a nd Assembly Section

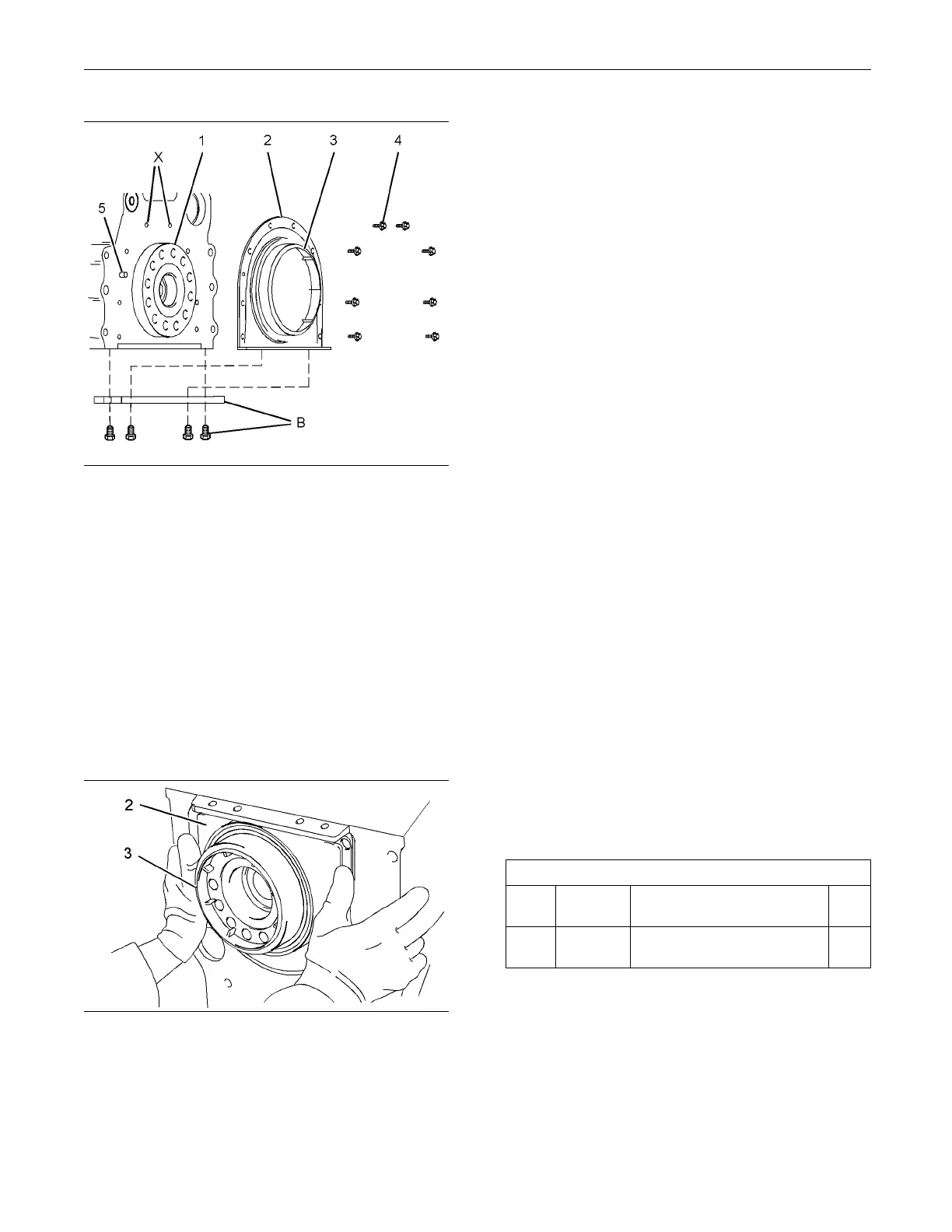

g01374593

Illustration 135

Typical exam p le

2. Ensure that crankshaft flange (1) is clean, dry and

free from damage.

3. Ensure that the mating surface of the cylinder

blockiscleananddry.

4. Ensure that plastic sleeve (3) is squarely installed

within new crankshaft rear seal (2).

Note: The plastic sleeve is included in order to

protect the lip of the seal as the crankshaft rear seal

is pushed over crankshaft flange (1). Do not attempt

to install a crankshaft rear seal without the plastic

sleeve.

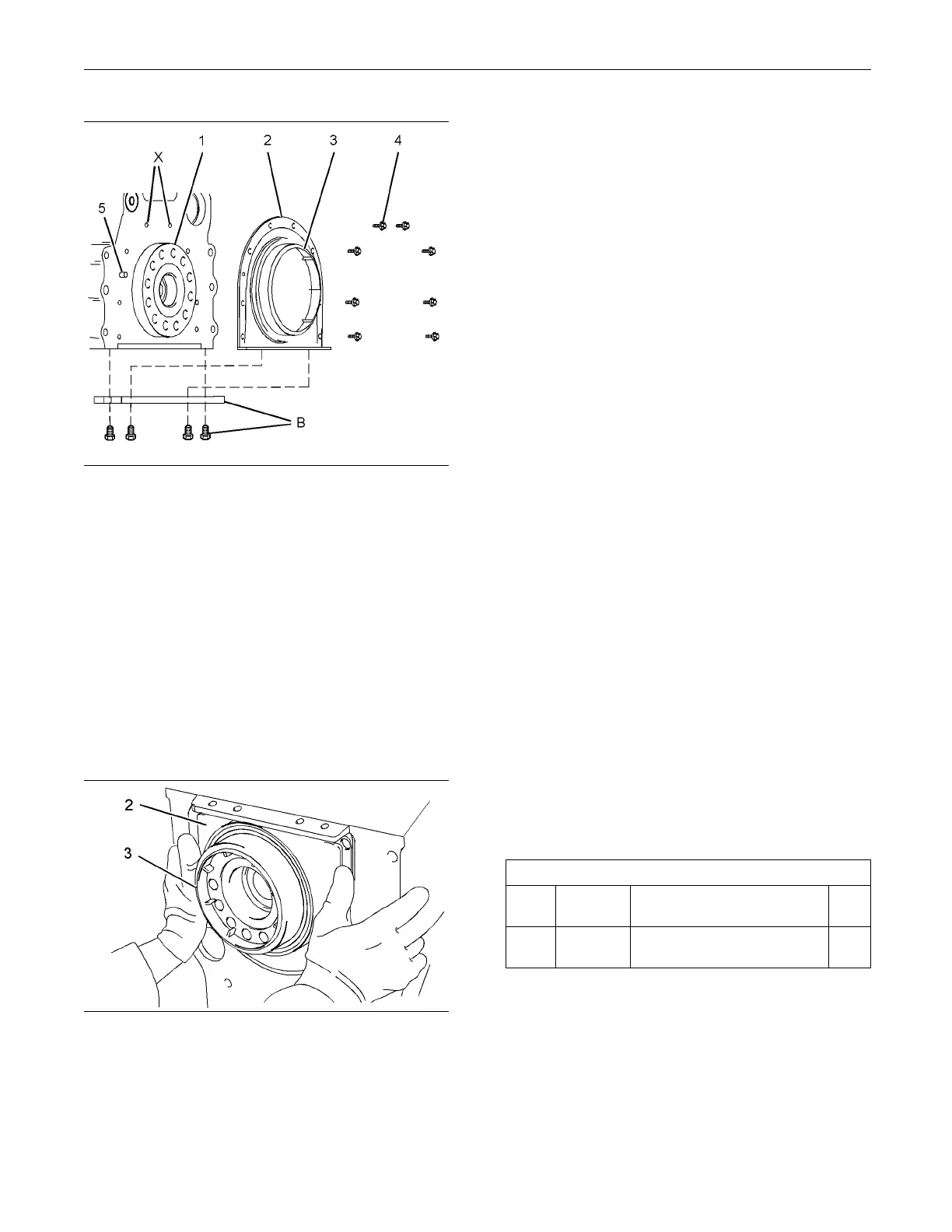

g01337517

Illustration 136

Typical exam p le

5. Place the assembly of the crankshaft rear seal

over crankshaft flange (1). Align dowel (5) with the

slot in the crankshaft rear seal.

6. Ensure that plastic sleeve (3) is engaged on

crankshaft flan

ge (1). Push crankshaft rear seal

(2) squarely onto the crankshaft. Ensure that the

crankshaft rear seal is seated against the cylinder

block. During

this process, plastic sleeve (3) will

be forced out of the crankshaft rear seal. Discard

the plastic sleeve.

Note: Ensure that dowel (5) is engaged in the hole in

the crankshaft rear seal.

7. Install Tooling (C) to the cylinder block and to

crankshaft rear seal (2). Tighten the bolts to a

torque of 15 N

·m (11 lb ft).

8. Use Tooling (B) in order to install two Torx bolts (4)

to crankshaf

t rear seal (3) in position (X). Tighten

two Torx bolts (4) to a torque of 22 N·m (16 lb ft).

9. Use Tooling

(B) in order to install remaining Torx

bolts (4). Tighten all Torx bolts (4) to a torque of

22 N·m (16 lb ft).

10. Remove Tooling (C).

End By:

a. Install the engine oil pan plate. Refer to

Disassembl

y and Assembly, “Engine Oil Pan Plate

- Remove and Install”.

i02654494

Flywheel Housing - Remove

and Install

(Standard

Housing)

Removal Procedure

Table 28

Required T

ools

Tool

Part

Number

Part Descr

iption

Qty

A

-

Guide Stud

(M10 by 100 mm)

2

Start By:

a. Remove the flywheel. Refer to Disassembly and

Assembly, “Flywheel - Remove”.

Loading...

Loading...