KENR6932 143

Disassembly and Assembly Section

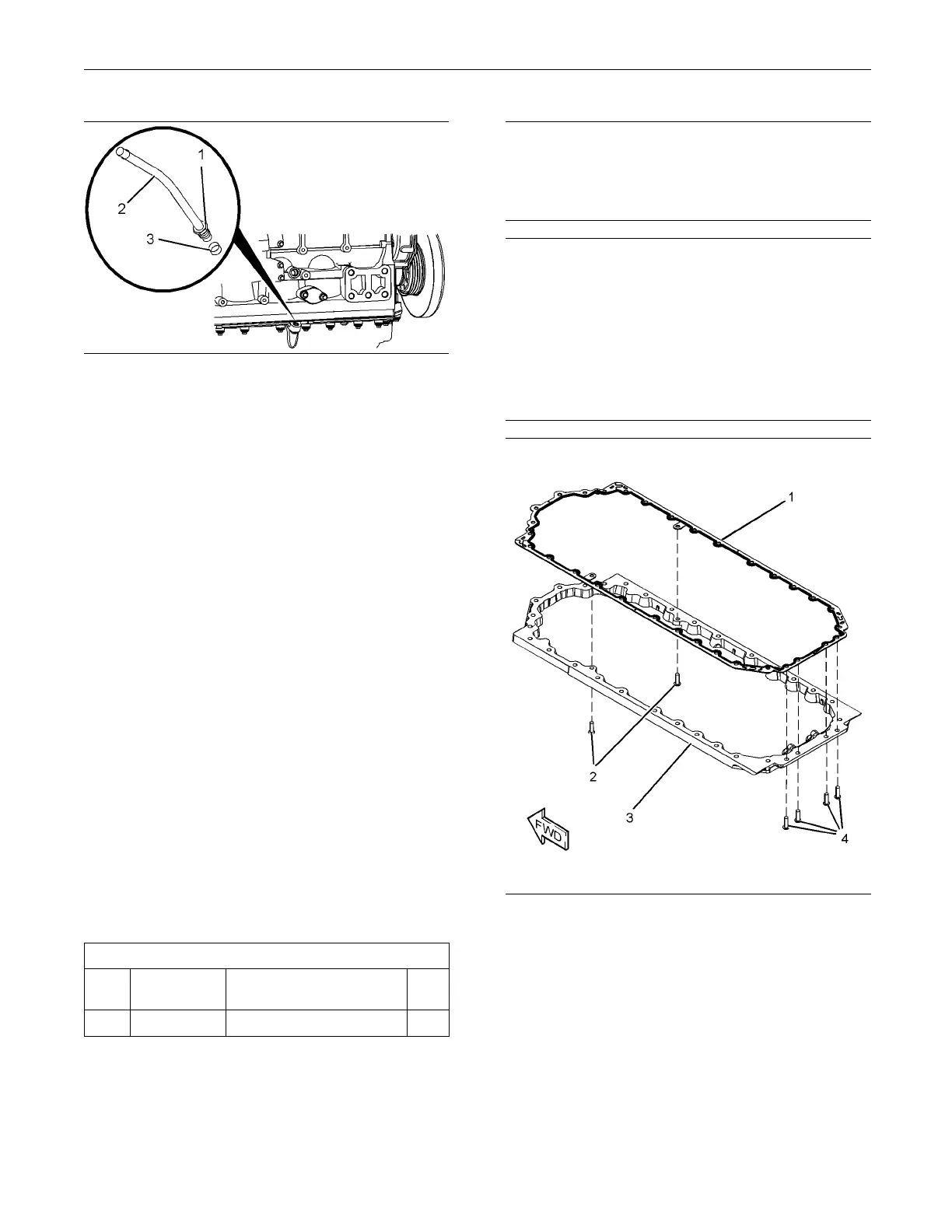

g01340605

Illustration 289

Typical exam p le

10. If necessary, follow Steps 10.a through 10.c in

order to install the assembly of the dipstick tube.

a. Install a new seal (3) to the tube assembly (2).

b. Apply Tooling (B) to the nut (1). Install the tube

assembly to the engine oil pan.

Note: Ensure that the orientation of the tube

assembly is correct.

c. Tightenthenut(1)toatorqueof18N·m

(13 lb ft). Install the dipstick (not shown).

11. Fill the engine oil pan to the correct level. Refer

to Operation and Maintenance Manual, “Oil Filter

Change” for the procedure.

i02652928

Engine Oil

Pan Plate - Remove

and Install

(Aluminum Oil Pan)

Removal Procedure

Table 64

Required Tools

Tool

Part

Number

Part Description Qty

A

-

T40 Torx Socket

1

Start By:

a. Remove the engine oil pan. Refer to Disassembly

and Assembly, “Engine Oil Pan - Remove”.

b. Remove the flywheel housing. Refer to

Disassembly and Assembly, “Flywheel Housing

- Remove and Install”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during perform

ance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compar

tment or disassembling any compo-

nent containing fluids.

Dispose of all

fluids according to local regulations and

mandates.

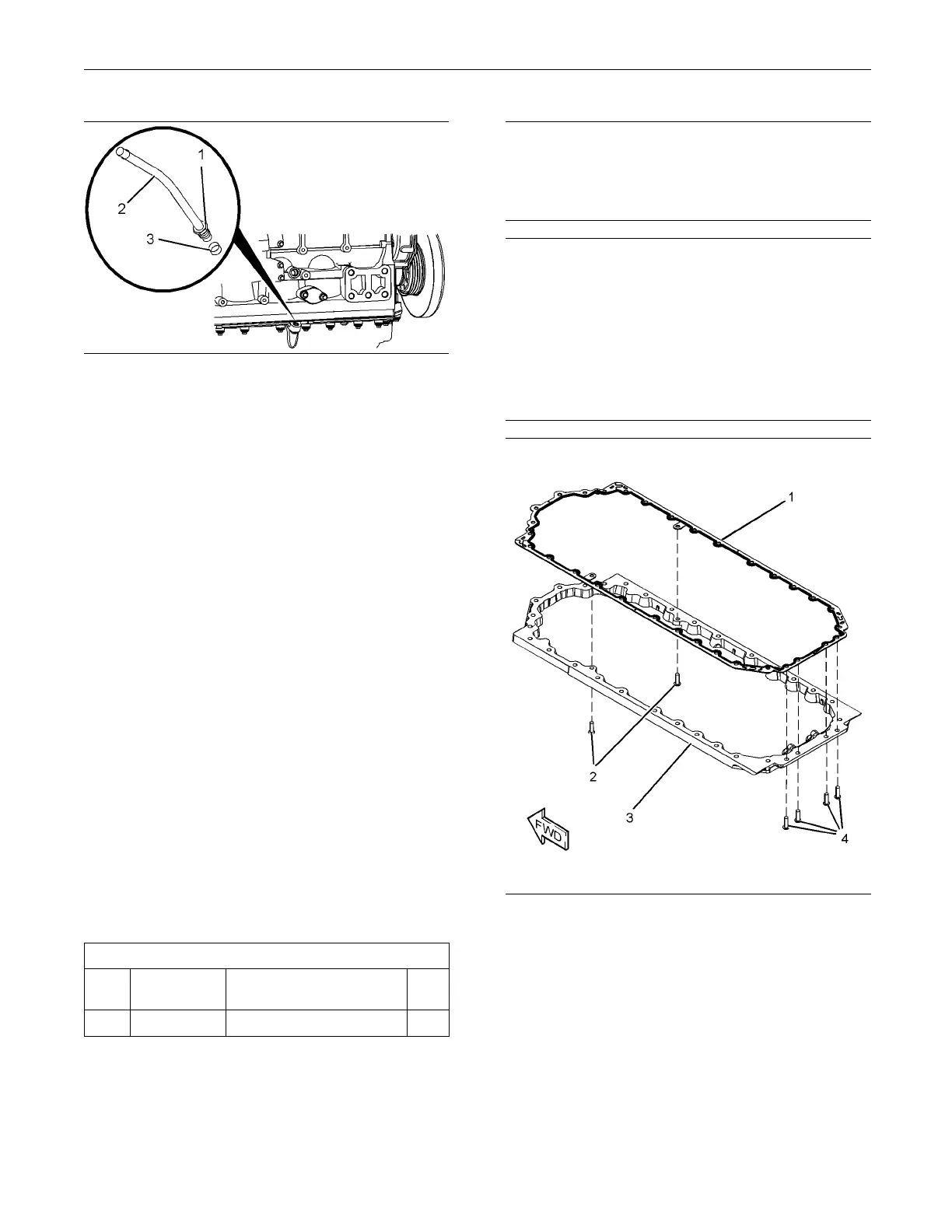

g01342059

Illustration 290

1. Remove isolating frame from the cylinder block.

Follow steps 1.a through 1.c in order to remove

the isolating frame from the cylinder block.

a. Support the isolating frame (3). Use Tooling (A)

to remove the torx screws (2) and (4).

b. Remove the isolating frame (3) from the

cylinder block.

c. Remove the joint (1).

Loading...

Loading...