150 KENR6932

Disassembly a nd Assembly Section

4. Lubricate the bush for piston pin (8) in the

connecting rod

and lubricate the bore for the

piston pin in piston (4) with clean engine oil.

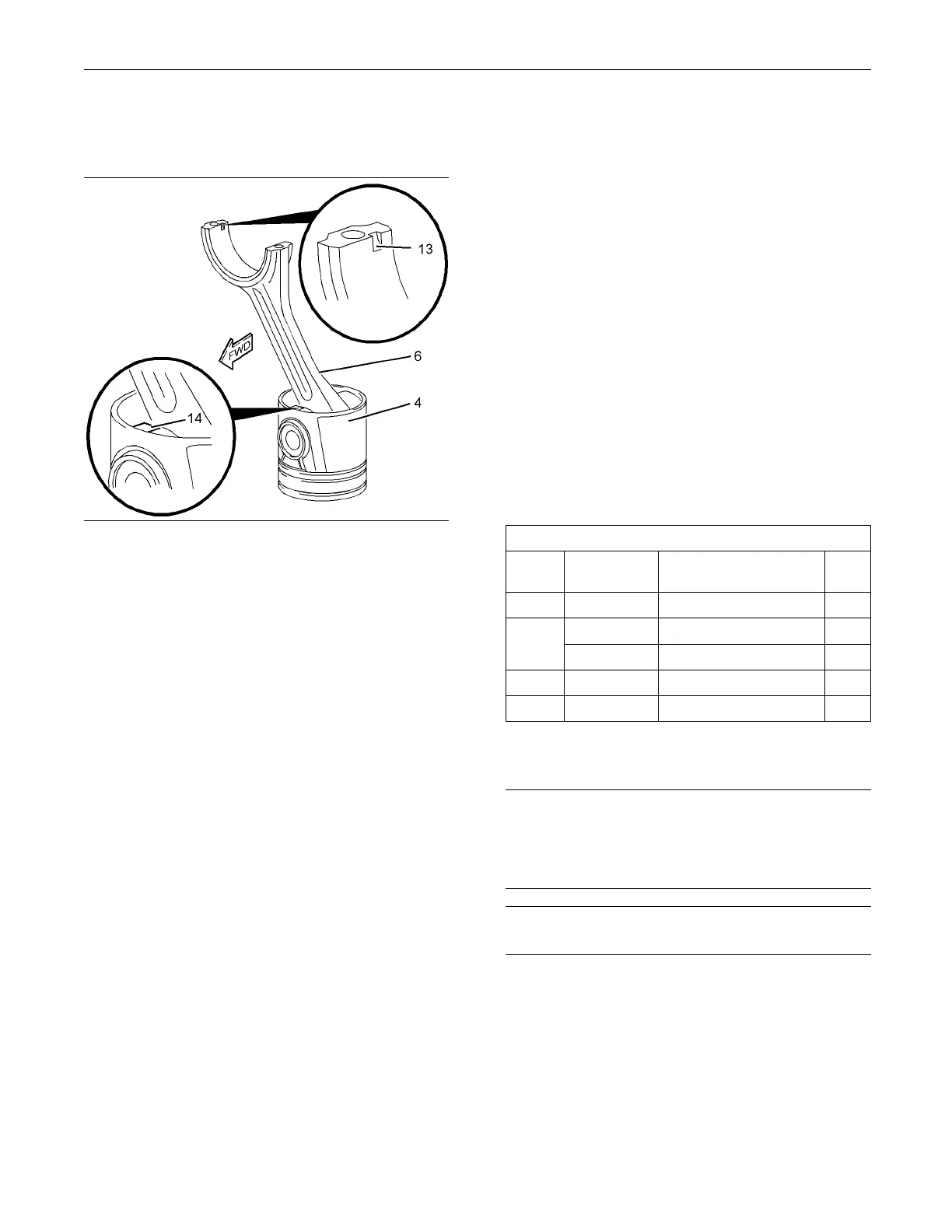

g01341313

Illustration 302

5. Place the piston on a suitable surface with the

crown downward. Install connecting rod (6) and

piston pin (7) to piston (4). Ensure that square (14)

on the piston, and slot (13) on the connecting rod

are in the correct position. See illustration 302.

Note: If the piston pin cannot be installed by hand,

heat the piston to a temperature of 45° ± 5°C

(113° ± 9°F).

6. Use Tooling (A) in order to install circlips (5) to the

piston pin bore in piston (4).

Note: Ensure that the circlips are seated in the

grooves in the piston.

7. Install upper bearing shell (9) into connecting rod

(6). Ensure that the locating tab for the upper

bearing shell is correctly seated in the slot in the

connecting rod.

8. Install lower bearing shell (10) into connecting rod

cap (11). Ensure that the locating tab for the lower

bearing shell is correctly seated in the slot in the

connecting rod cap.

9. Repeat Steps 2 through 8 for the remaining piston

and connecting rod assemblies.

Note: Fracture split connecting rods should not be

left without th

e connecting rod caps installed. After

the assembly procedure for the piston and connecting

rod is completed, carry out the installation procedure

as soon as poss

ible. Refer to Disassembly and

Assembly, “Piston and Connecting Rods - Install”.

End By:

a. Install the pistons and the connecting rods.

Refer to Disa

ssembly and Assembly, “Piston and

Connecting Rods - Install”.

i02654531

Pistons and Connecting Rods

-Install

Installation Procedure

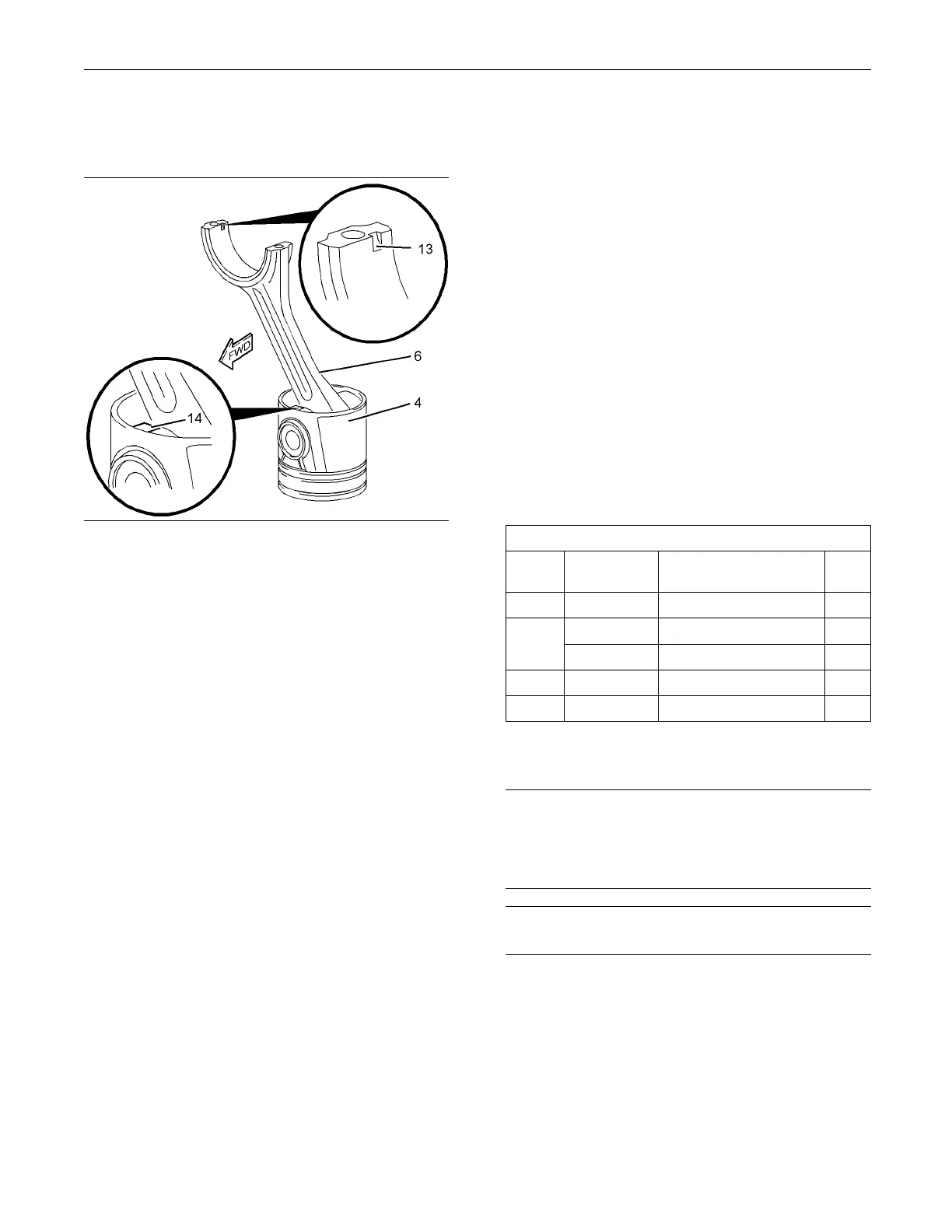

Table 71

Required Tools

Tool Part

Number

Part Description

Qty

A

21825576

Crankshaft Turning Tool

1

27610291

Barring Device Housing 1

A

27610289

Gear

1

B

21825491

Piston Ring Compressor 1

C

21825607

Angle gauge 1

Note: EitherTooling(A)canbeused.UsetheTooling

that is most suitable.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Discard all used Connecting Rod fasteners.

1. If the connecting rod caps were temporarily

installed, remove the connecting rod caps. If

necessary, thoroughly clean all of the components.

2. Apply clean engine oil to the cylinder bore, to the

piston rings, to the outer surface of the piston and

to the bearing shells for the connecting rod.

Loading...

Loading...