KENR6932 9

Disassembly and Assembly Section

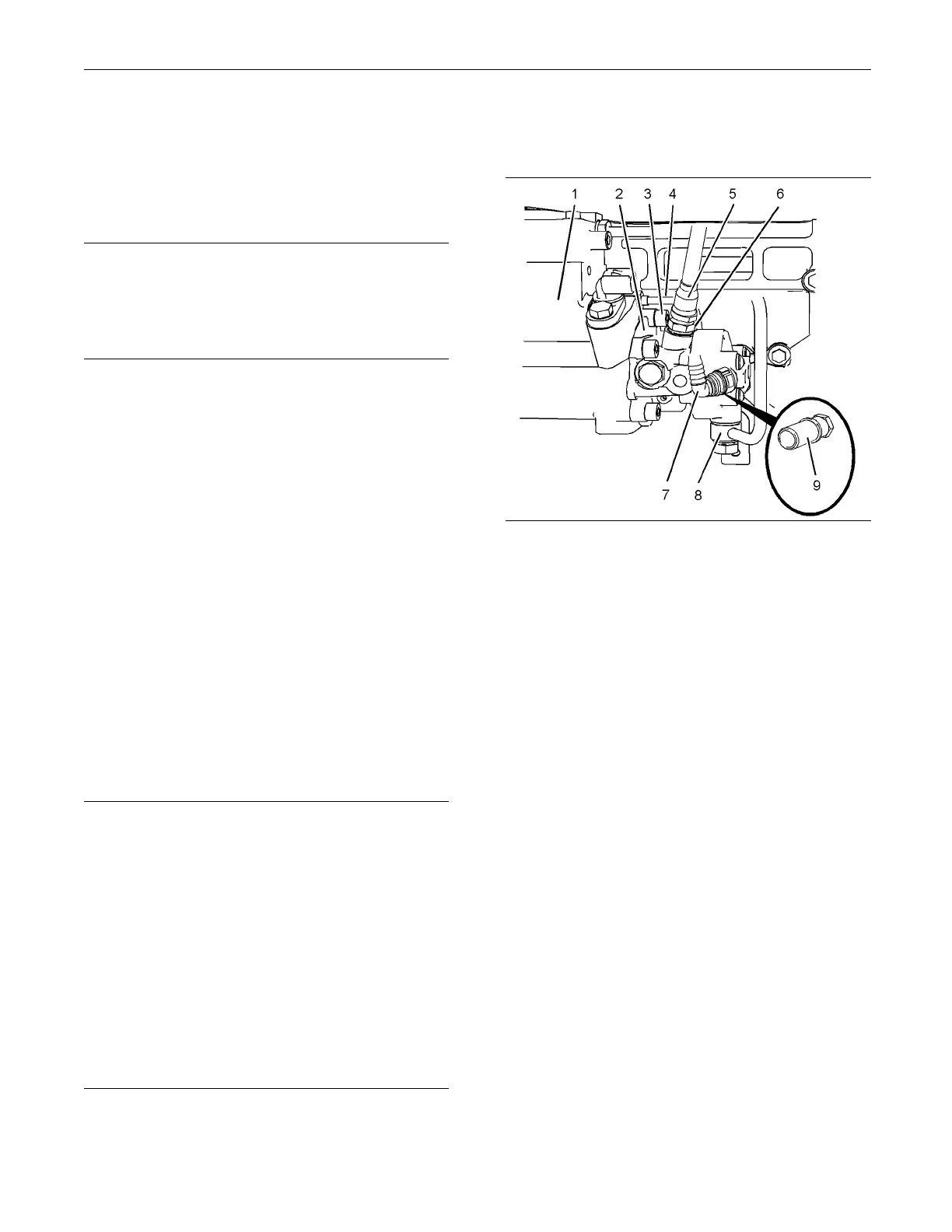

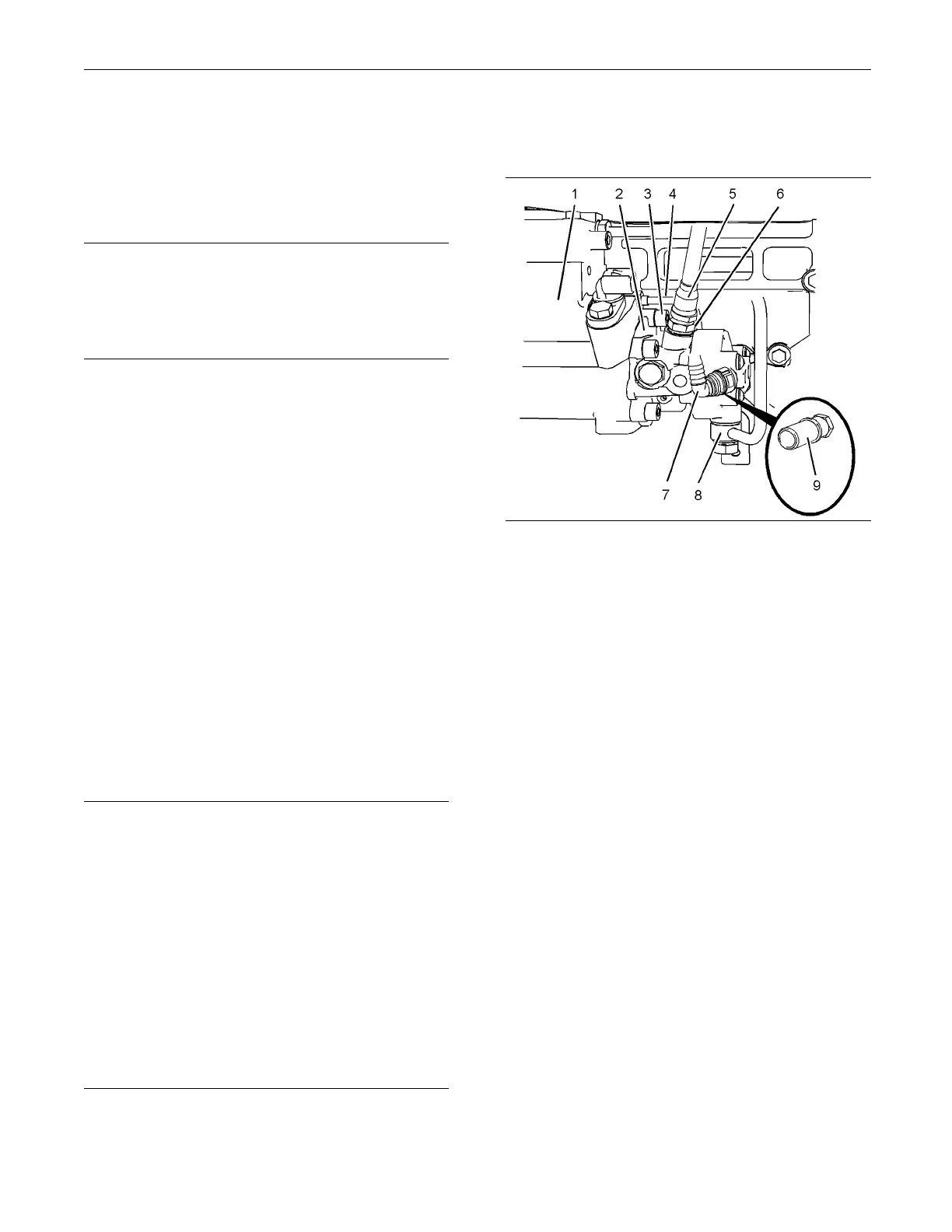

2. Position fuel filter base (1) on the mounting

bracket. Insta

ll bolts (3). Tighten the bolts to a

torque of 44 N·m (32 lb ft).

3. Remove the plu

gs from the plastic tube

assemblies. Remove the caps from the ports in

the fuel filter base.

NOTICE

Ensure that th

e plastic tube assemblies are installed

in the original positions. Failure to connect the plastic

tube assemblies to the correct ports will allow contam-

ination to en

ter the fuel system. Contaminated fuel will

cause serious damage to the engine.

4. Connect plas

tic tube assemblies (2), (4) and (5) to

fuel fi lter base (1).

5. If necessary

, install a new fuel filter (6) to fuel filter

base (1). Refer to Operation and Maintenance

Manual, “Fuel System Secondary Filter - Replace”

for the corr

ect procedure.

6. Restore the fuel supply.

End By:

a. Remove the a

ir from the fuel system. Refer to

Operation and Maintenance Manual, “Fuel System

- Prime”.

i02654514

Fuel Transfer Pump - Re m o ve

Removal Procedure

NOTICE

Ensure that all adjustments and repairs that are

carried out to the fuel system are performed by

authorised

personnel that have the correct train-

ing.

Before begi

ning ANY work on the fuel system, re-

fer to Operation and Maintenance Manual, “Gen-

eral Hazard Information and High Pressure Fuel

Lines” for

safety information.

Refer to System Operation, Testing and Adjusting,

“Cleanlin

ess of Fuel System Components” for de-

tailed information on the standards of cleanliness

that must be obs erved during ALL work on the fu-

el system

.

1. Isolate the fuel supply.

2. Place a suitable container below fuel transfer

pump (2) in orde

r to catch any fuel that might be

spilled.

g01334899

Illustration 7

Typical example

3. Remove plastic tube assembly (7) from fuel

transfer pump (2).

Note: If the tube assembly has quick fit connections,

ensure that the connections are clean before the tube

assembly is plugged.

4. Disconnect plastic tube assembly (5) from the

outlet of fuel transfer pump (2).

Note: If the tube assembly has quick fit connections,

ensure that the connections are clean before the tube

assembly is plugged.

5. Remove connector (6) from fuel transfer pump (2).

Remove the O-ring seal from connector (6).

If necessary, remove connector (9) from fuel

transfer pump (2). Remove the O-ring seal from

the connector (9).

6. Remove tube assembly (8) for the fuel return from

the fuel transfer pump and the cylinder head.

Note: Disconnect the tube assembly at the fuel

transfer pump first in order to drain the fuel from the

cylinder head.

7. Remove tube assembly (4) for the engine oil

supply from fuel injection pump (1).

8. Plug or cap all open ports and tube assemblies

immediately with new plugs or caps.

Loading...

Loading...