90 KENR6932

Disassembly a nd Assembly Section

Note: Either Tooling (A) can be used. Use the Tooling

that is most sui

table. Care must be taken in order to

ensure that the fuel injection pump timing is not lost

during the removal of the front gear group. Carefully

follow the pro

cedure in order to remove the gear

group.

1. Use Tooling (

A) in order to rotate the crankshaft

so that number one piston is at top dead center

on the compression stroke. Refer to System

Operation, T

esting and Adjusting, “Finding Top

Centre Position for No.1 Piston”.

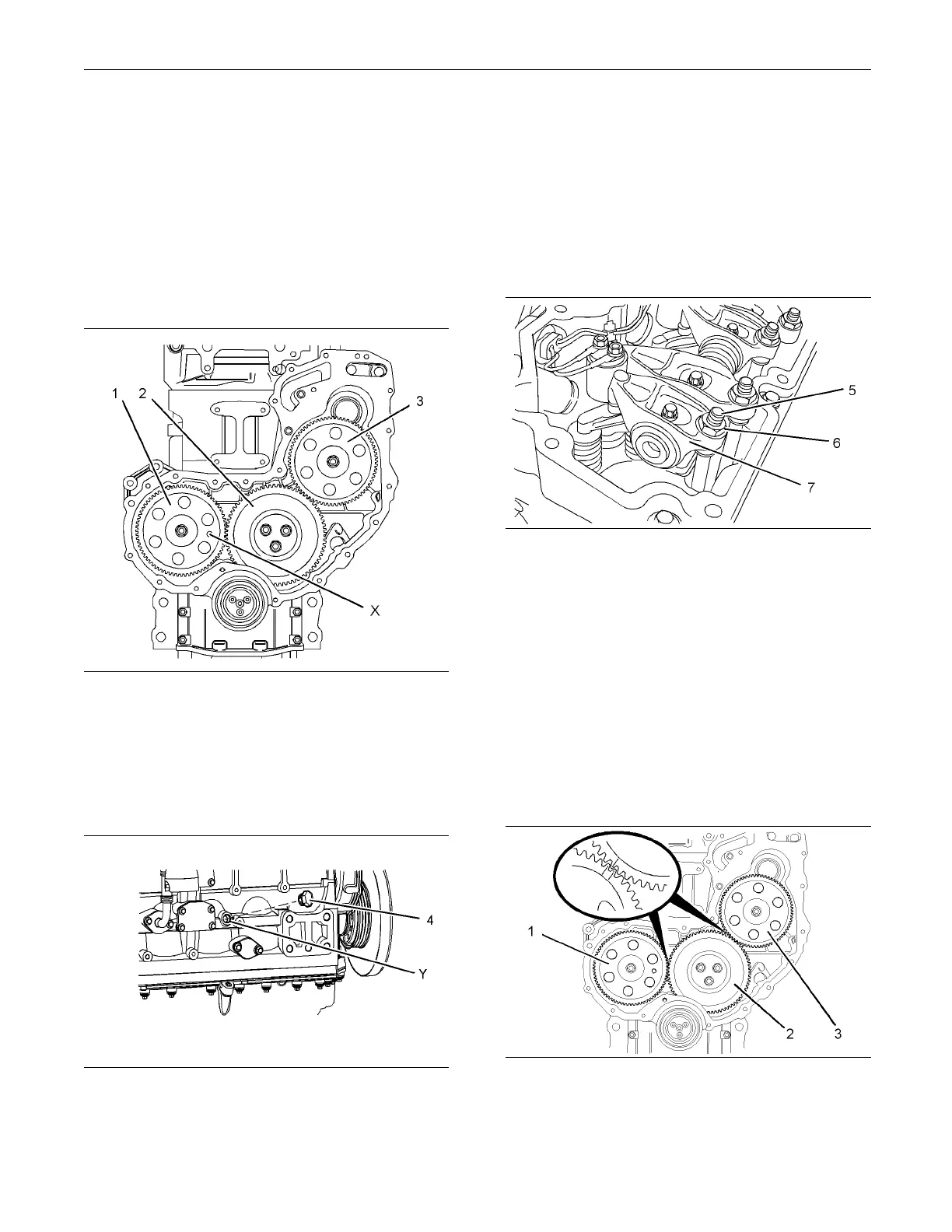

g01335379

Illustration 158

Typical exam p le

2. Install Tooling (B) through hole (X) in camshaft

gear (1) into the front housing. Use Tooling (B) in

order to lock the camshaft in the correct position.

Refer to System Operation, Testing and Adjusting,

“Finding Top Centre Position for No.1 Piston”.

g01335380

Illustration 159

3. Remove plug (4) from the cylinder block. Install

Tooling (C) int

ohole(Y)inthecylinderblock.

Use Tooling (C) in order to lock the crankshaft in

the correct position. Refer to System Operation,

Te st i ng a n d A d

justing, “Finding Top Centre

Position for No.1 Piston”.

Note: Do not u

se excessive force to install Tooling

(C). Do not use Tooling (C) to hold the crankshaft

during repairs.

g01337898

Illustration 160

4. Loosen nuts (6) on all rocker arms (7). Unscrew

adjusters (5) on all rocker arms (7) until all valves

are fully closed.

Note: Failure to ensure that ALL adjusters are fully

unscrewed can result in contact between the valves

and pistons.

5. Apply sufficient pressure to fuel injection pump

gear (3) in a counterclockwise direction in order

to remove the backlash. Lock the fuel injection

pump in this position. Refer to Disassembly and

Assembly, “Fuel Pump Gear - Remove” for the

correct procedure.

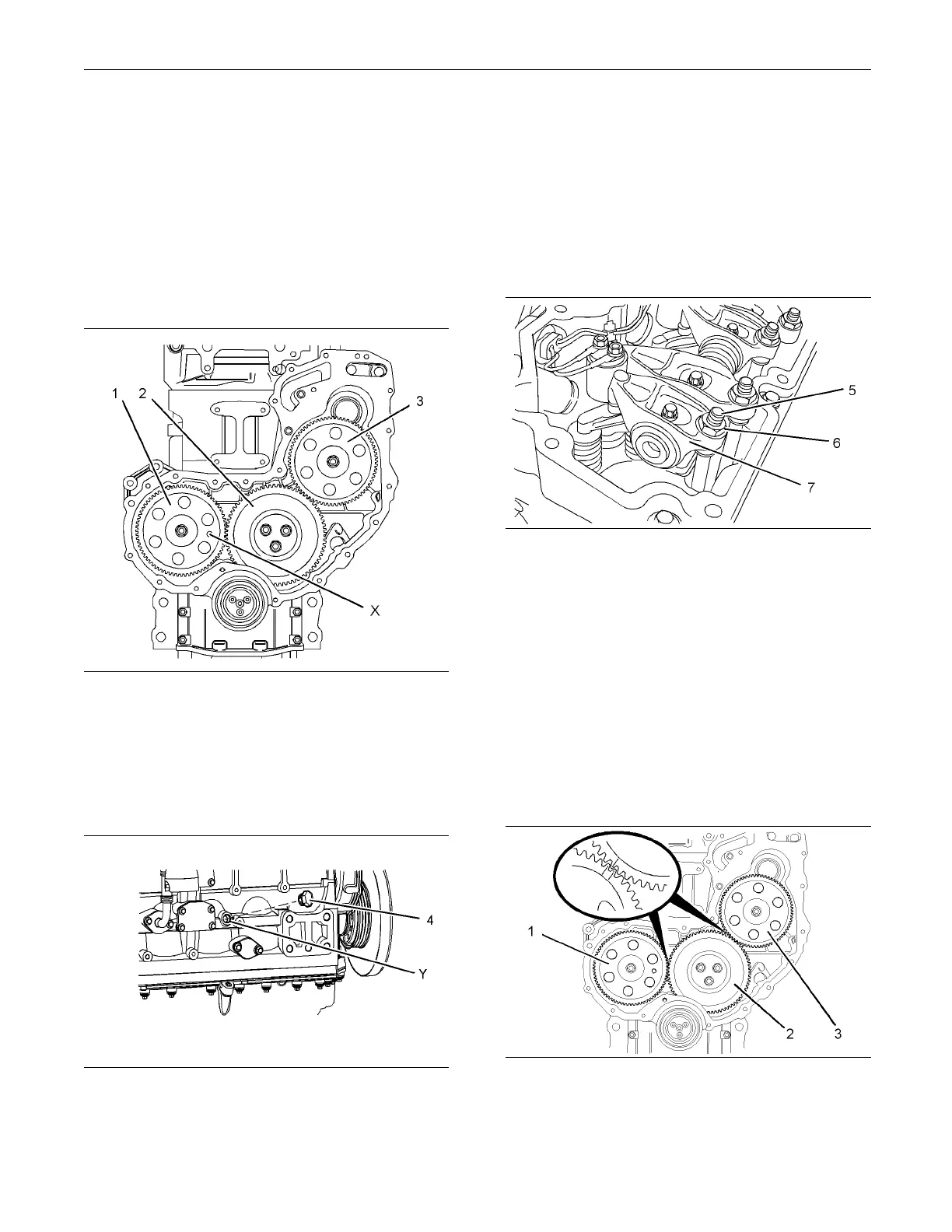

g01335384

Illustration 161

Typical example

6. Mark gears (1), (2) and (3) in order to show

alignment. Refer to Illustration 161.

Loading...

Loading...