CLUTCH

6.13

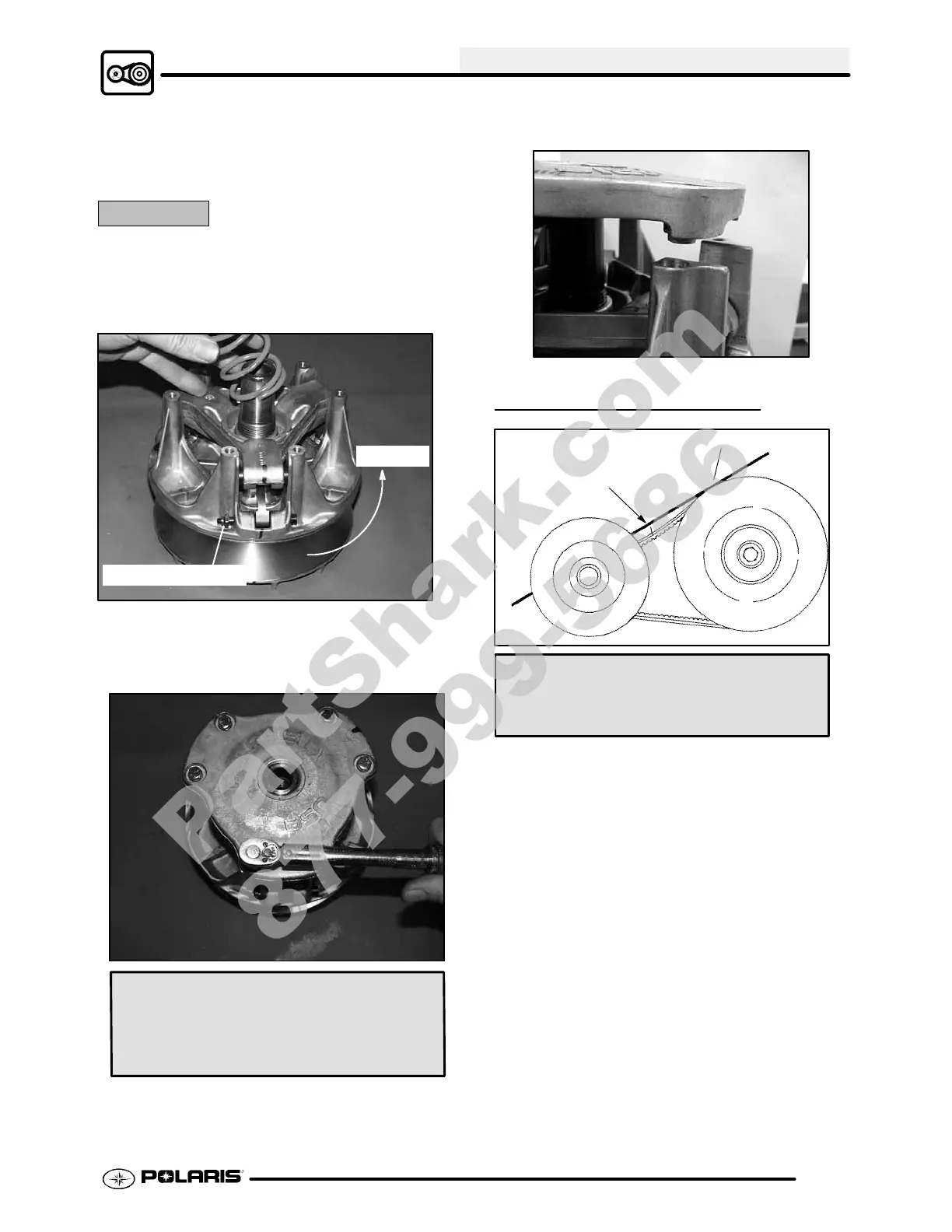

5. Torque spider to specification using the holding

fixture and spider tool. Torque with smooth

motionto avoiddamagetothestationarysheave.

Refer to Page 6.2 for torque specification.

CAUTION:

Be sure the spider spacer washers are fully seatedin

therecessedareainthespider. Any misalignmentwill

alter clutch balance. Inverting the clutch whileinitially

tightening the spider will help position the washers.

Rotation

Nut on trailing side

6. Install shift weights using new lock nuts on the

bolts.

7. Reinstall clutch spring.

Spider Torque:

200 ft. lbs. (276 Nm)

Cover Screw Torque:

90 in. lbs. (10.4 Nm)

8. Reinstall cover, aligning bosses onthe tower and

cover. Torquecover bolts evenlytospecification.

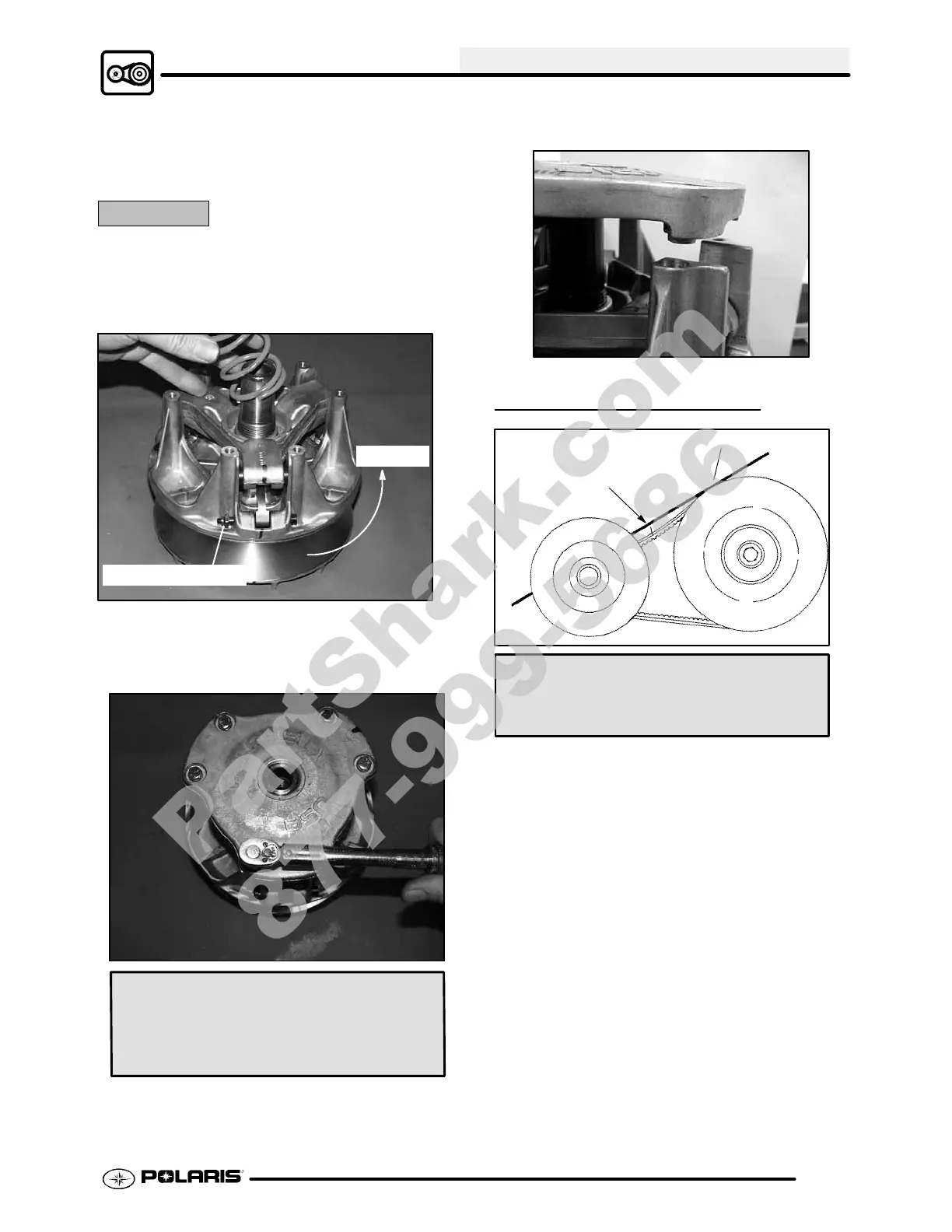

DRIVE BELT TENSION

11/8″ (28.5 mm)

Straight Edge

Belt Deflection (Tension):

11/8″ (2.9 cm) - 1 1/4″ (3.2 cm)

NOTE: Pinchthesheaveslightlytogether withclamp

to prevent the belt from being pushed into the driven

sheave.

1. Place a straight edge on top of the belt between

drive and driven clutch.

2. Pushdownondrivebeltuntilitislightlytensioned.

3. Measure belt deflection as shown in photo.

NOTE: If belt deflection is out of specification, adjust

by removing or adding shims between the driven

clutch sheaves.

G Remove shims to decrease belt

deflection

G Add shimstoincreasebelt deflection

See DRIVEN CLUTCH

DISASSEMBLY/INSPECTION, Pages 6.19 - 6.20.

PartShark.com

877-999-5686

Loading...

Loading...