CLUTCH

6.23

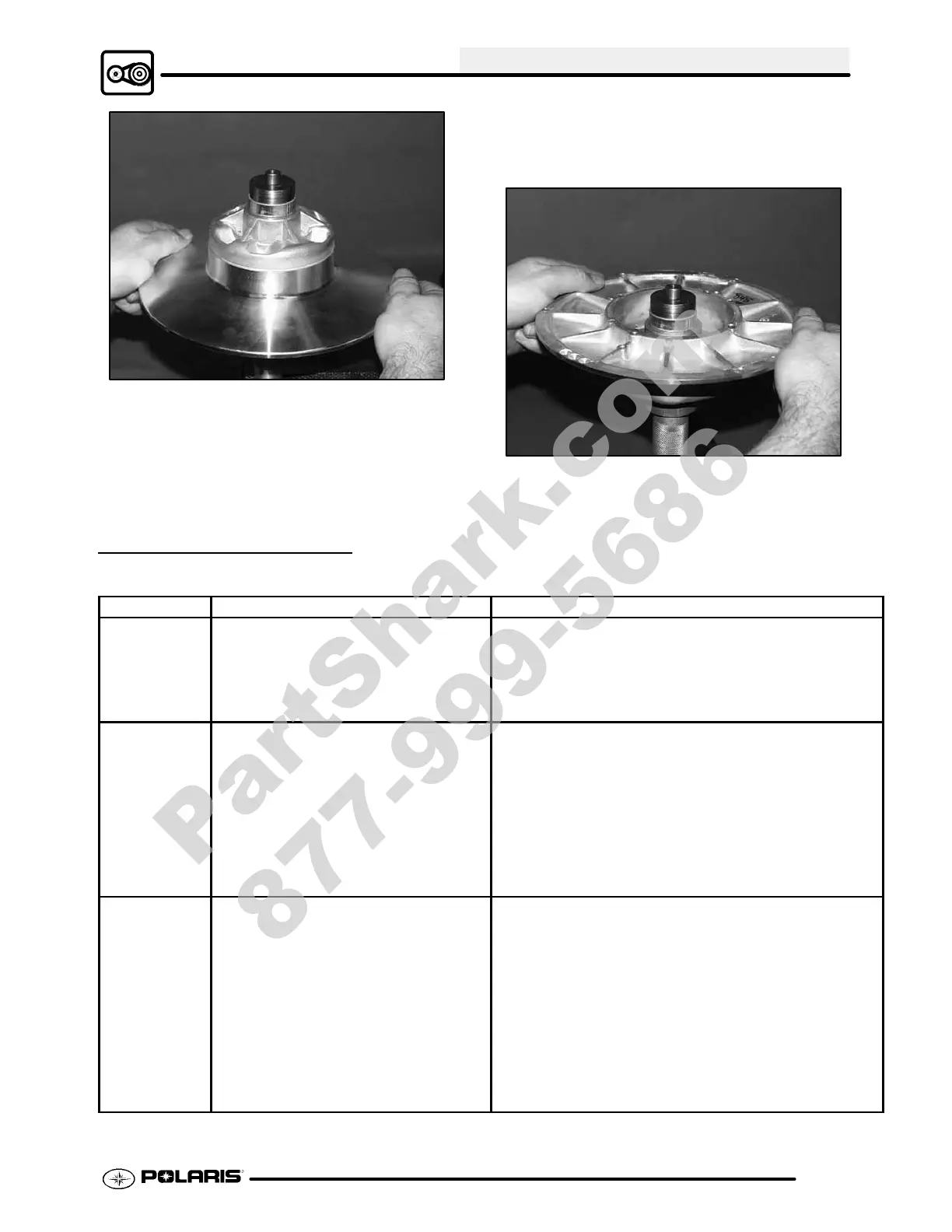

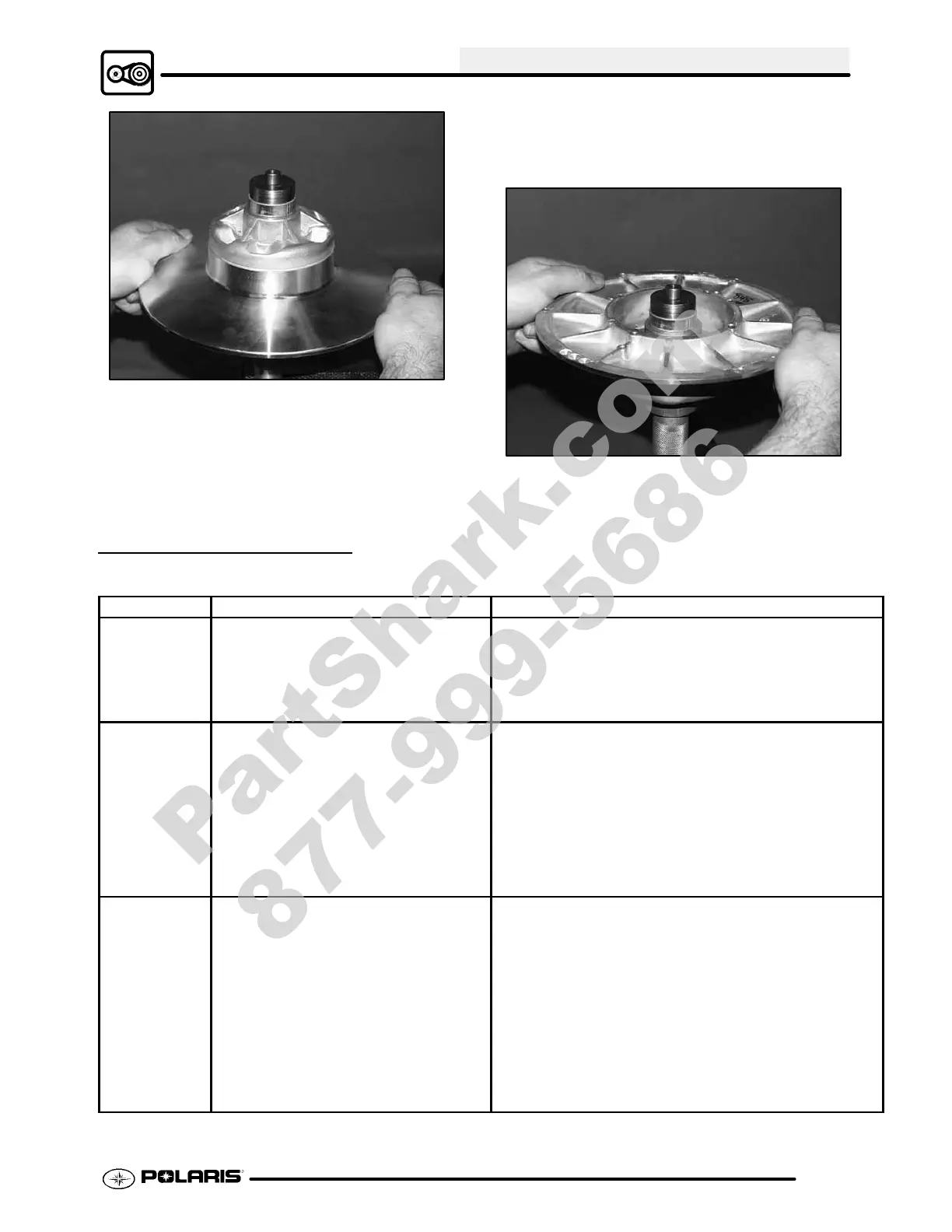

4. Installnutontopullerrodandhandtightenagainst

installation tool.

5. Turn clutch sheave counterclockwise until

bushing is seated.

6. Remove nut from puller rod and set aside.

7. Remove installation tool and clutch sheave from

puller.

8. Repeatinstallation procedurefor other moveable

bushing.

TROUBLESHOOTING

Situation Probable Cause Remedy

Engine RPM

below specified

operating

range, although

engine is prop-

erly tuned.

-Wrong or broken drive clutch spring.

-Drive clutch shift weight too heavy.

-Drivenclutchspringbrokenorinstalledin

wrong helix location.

-Replace with recommended spring.

-Install correct shift weight kit to match engine application.

-Replace spring; refer to proper installation location.

Erratic engine

operating RPM

during accelera-

tion or load vari-

ations.

-Drive clutch binding.

-Belt worn unevenly - thin/burnt spots

-Driven c lutch malfunction.

-Sheave face grooved.

a. Disassemble drive clutch; inspect shift weights for wear

and free operation.

b. Clean and polish stationary shaft hub; reassemble clutch

without spring to determine problem area.

Replace belt

a. Replace ramp buttons.

b. Inspect movable sheave for excessive bushing clearance/

replace.

-Replace the clutch.

Engine RPM

above specified

operating

range.

-Incorrectdriveclutchspring(toohigh

spring rate).

-Drive clutch shift weights incorrect for ap-

plication (too light).

-Drive clutch binding.

-Driven clutch binding.

-Converter sheaves greasy; belt slippage.

-Install correct recommended spring.

-Install correct recommended shift weights.

-Disassemble and clean clutch, inspecting shift weights and

rollers. Reassemble without the spring and move sheaves

through entire range to further determine probable cause.

-Disassemble, clean, and inspect driven clutch, noting worn

sheave bushing and ramp buttons and helix spring location.

-Clean sheaves with denatured alcohol or brake cleaner,

install new belt.

PartShark.com

877-999-5686

Loading...

Loading...