ENGINE

3.34

CRANKSHAFT

INSTALLA

TION

Lubricate all bearings with clean engine oil before

assembly.

1. Install the crankshaft into the PT O side

crankcase.

2. Install the proper shim on the magnetoend of the

crankshaft.

CRANKCASE OIL STRAINER

INSPECTION

1. Removebolt securingoilstrainertotheMAG side

crankcase.

2. Remove oil strainer and visually inspect for any

rips, tears or obstructions in screen.

3. Replace oil strainer if it fails visual inspection.

CRANKCASE REASSEMBLY

1. Apply Crankcase Sealant (PN 2871557)tothe

crankcase mating surfaces. Be sure the

alignment pins are in place.

2. Set the crankcase in position carefully. Mate the

crankcase halves by tapping lightly with a soft

faced hammer . Continually check alignment of

the cases during installation, closing the gap

equally until the surfaces are tightly sealed.

3. Install the crankcase flange bolts and tighten to

specifiedtorquein3stepsaccordingtothetorque

pattern. See Page 3.4.

Crankcase Bolt Torque:

14-15 ft. lbs. (19-21 Nm)

Crankcase Sealant :

(PN 2871557)

OIL PUMP INSTALLATION

1. Inspect the oil pump sealing surface on the

crankcase. Apply a light film of engine oil to the

surfaces. Install outer and inner rotors over

crankshaft .

2. Installoilpumpcover. Torquescrewstospecified

torque.

Oil Pump Cover Screw Torque:

4-5 ft. lbs. (5-7 Nm)

NOTE: Do not usegasket sealer on thepumpmating

surfaces.

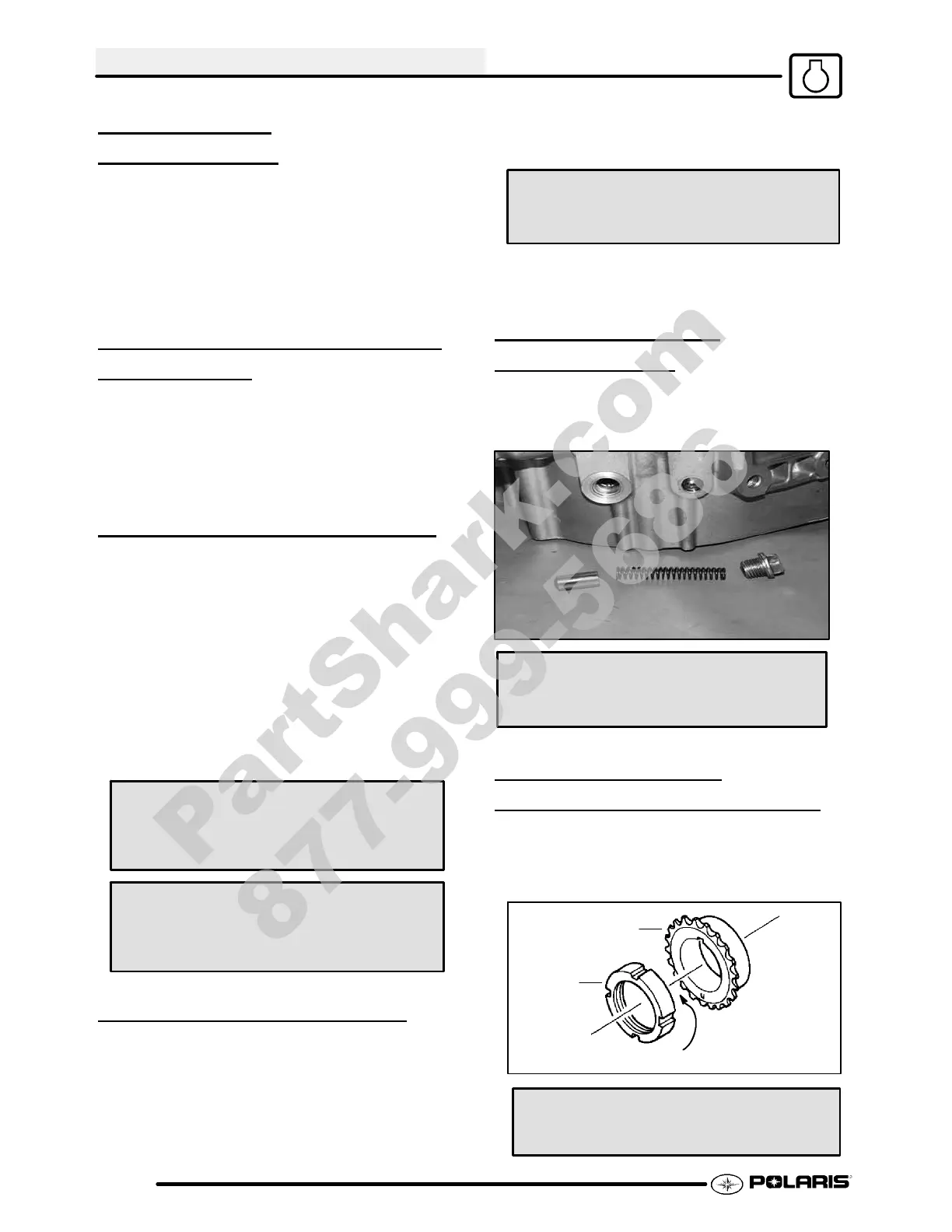

OILRELIEFVALVE

INSTALLA

TION

Installtheoil relief valve, spring, and plugusing anew

sealing washer.

Oil Relief Valve Plug Torque:

14-17 ft. lbs. (19-23 Nm)

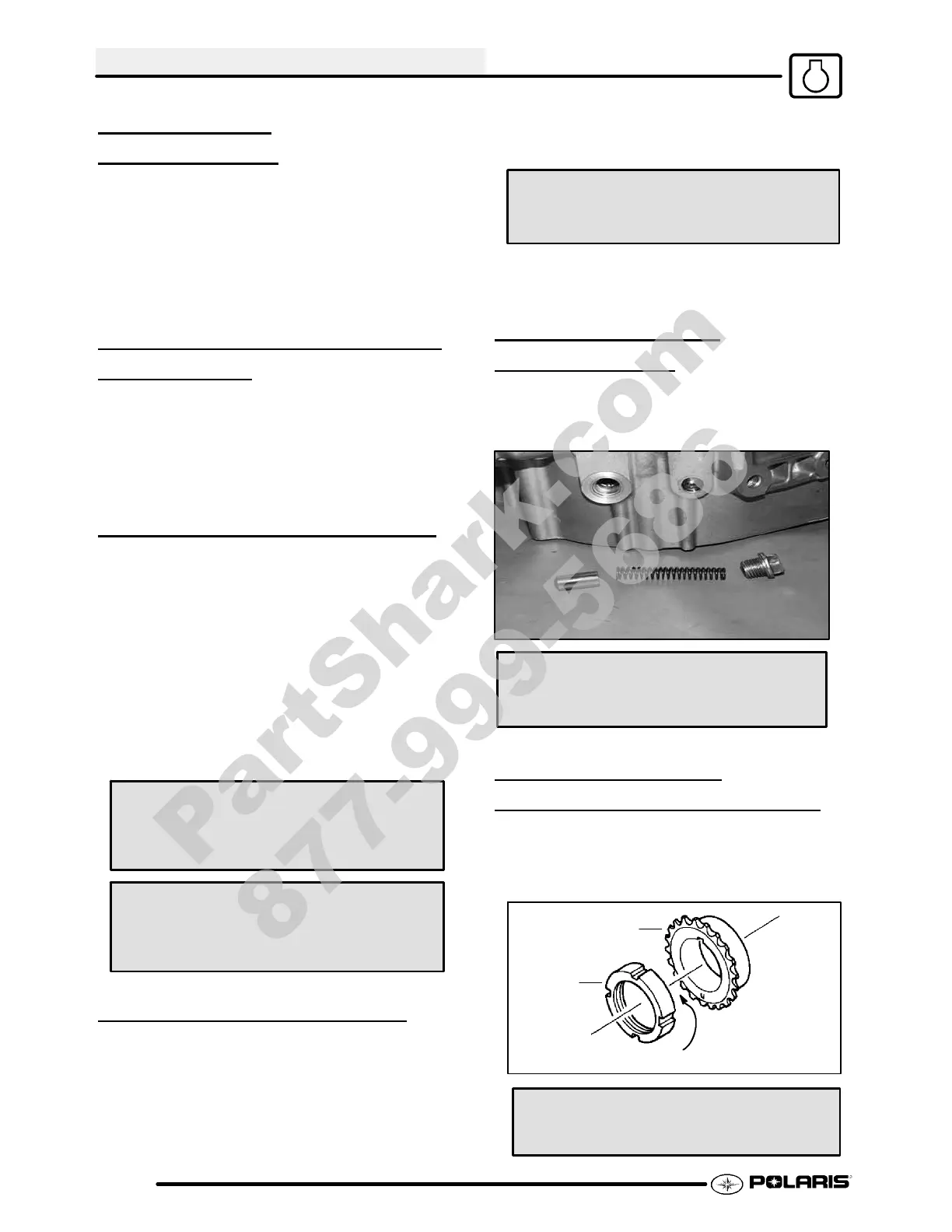

CAM CHAIN DRIVE

SPROCKET INSTALLA

TION

1. Install the Woodruff key, drive sprocket, and

slotted nut. Using the Slotted Nut Socket (PN

2871293), tighten the nut to the specified torque.

A

B

T ighten

Slotted Nut Torque:

45 ft. lbs. (61 Nm)

PartShark.com

877-999-5686

Loading...

Loading...