ENGINE

3.17

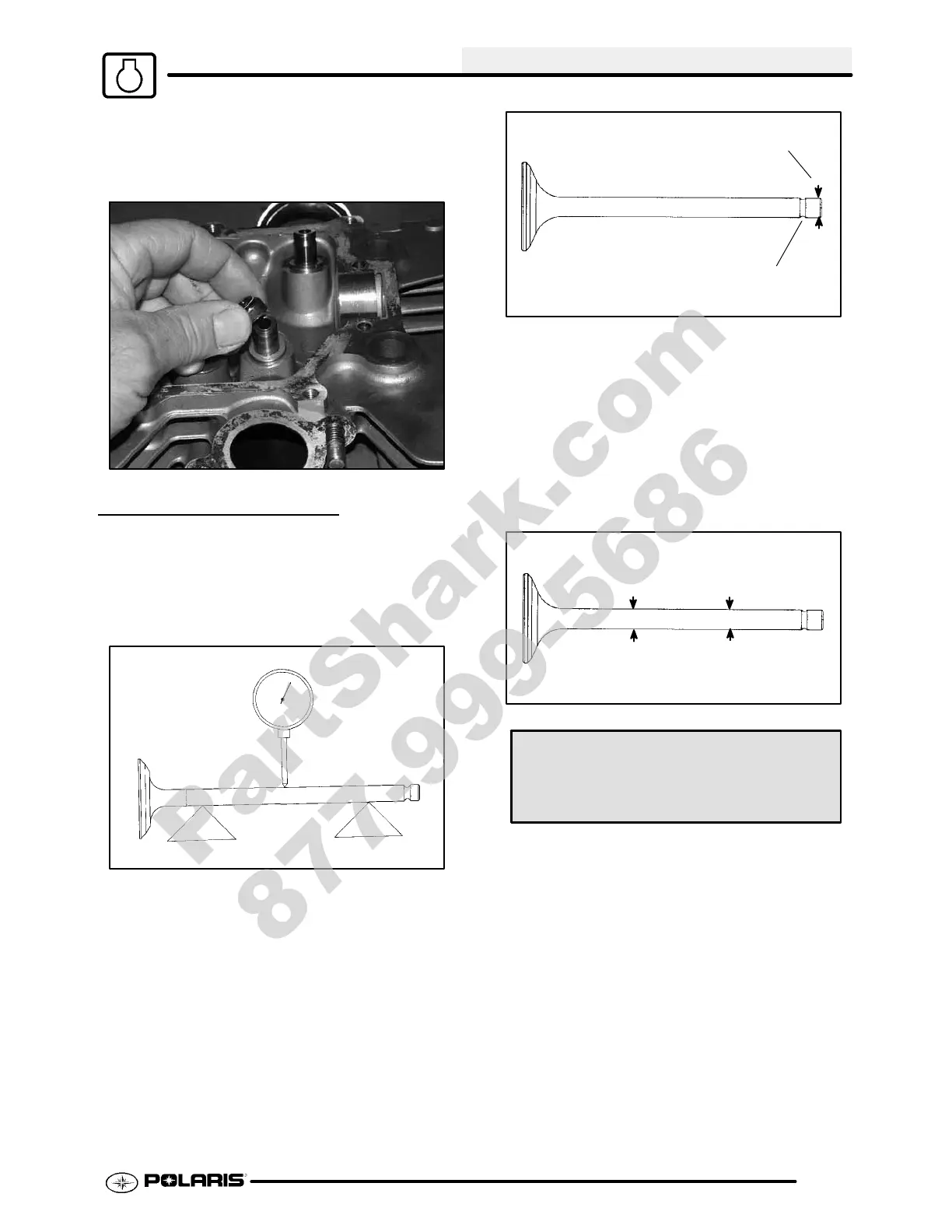

5. Remove valve seals. CAUTION: Replace seals

whenever the cylinder head is disassembled.

Hardened, cracked orworn valveseals will cause

excessive oil consumption and carbon buildup.

VALVE INSPECTION

1. Remove all carbon from valve with a soft wire

wheel.

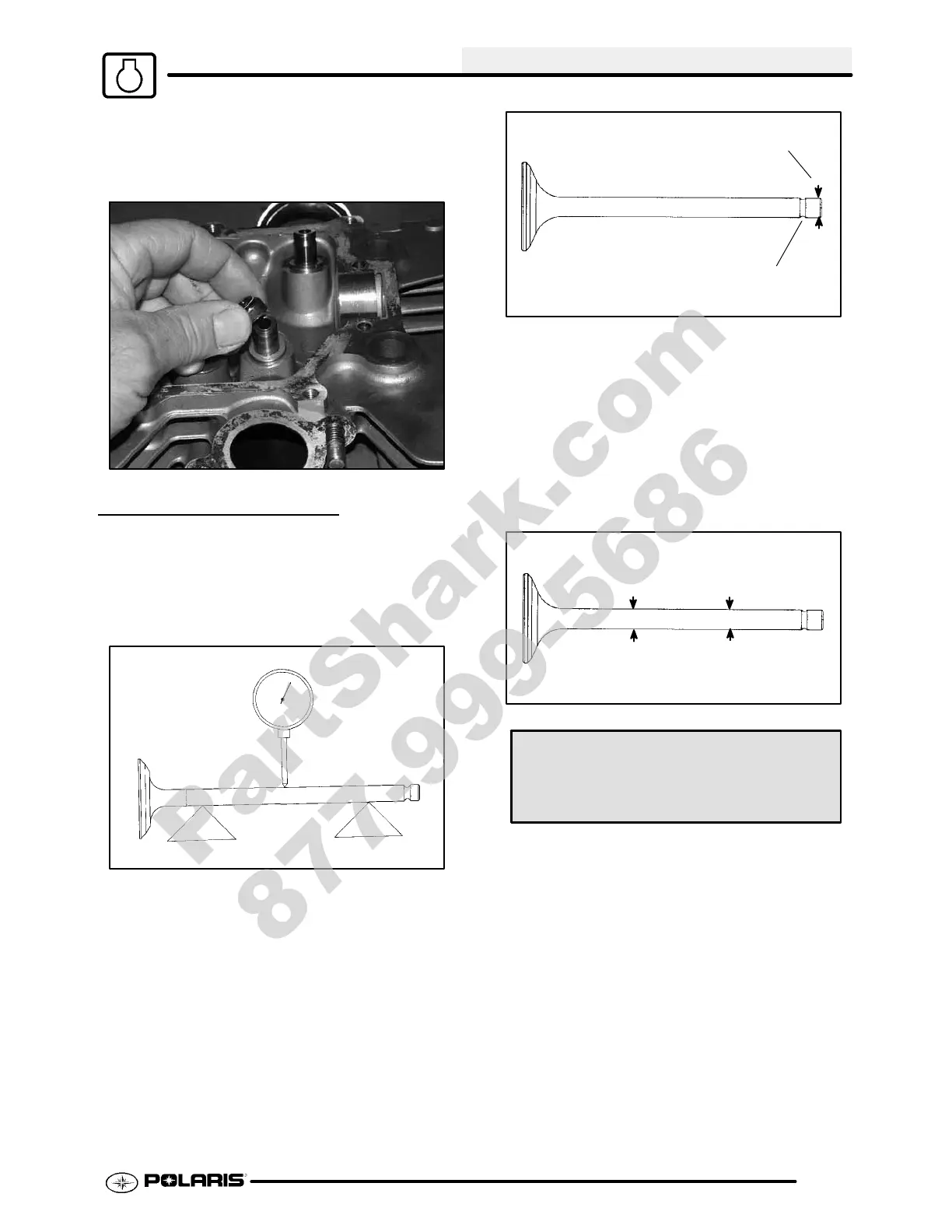

2. Check valve face for runout, pitting, and burnt

spots. To check for bent valve stems, mount

valve in a drill or use “V” blocks and a dial

indicator.

3. Check end of valve stem for flaring, pitting, wear

or damage (A).

A

B

4. Inspect split keeper groove for wear or flaring of

the keeper seat area (B). NOTE: The valves

cannot be re-faced or end ground. They must be

replaced if worn, bent, or damaged.

5. Measure diameter of valve stem with a

micrometer in three places and in two different

directions (six measurements total). Compare to

specifications.

Measure valve stem in

several places.

Valve Stem Diameter:

Intake: .2343-.2348I (5.950-5.965 mm)

Exhaust: .2341-.2346I (5.945-5.960 mm)

6. Measure valve guide inside diameter at the top

middle and end of the guide using a small hole

gauge and a micrometer. Measure in two

directions, front to back and side to side.

PartShark.com

877-999-5686

Loading...

Loading...