ENGINE

3.23

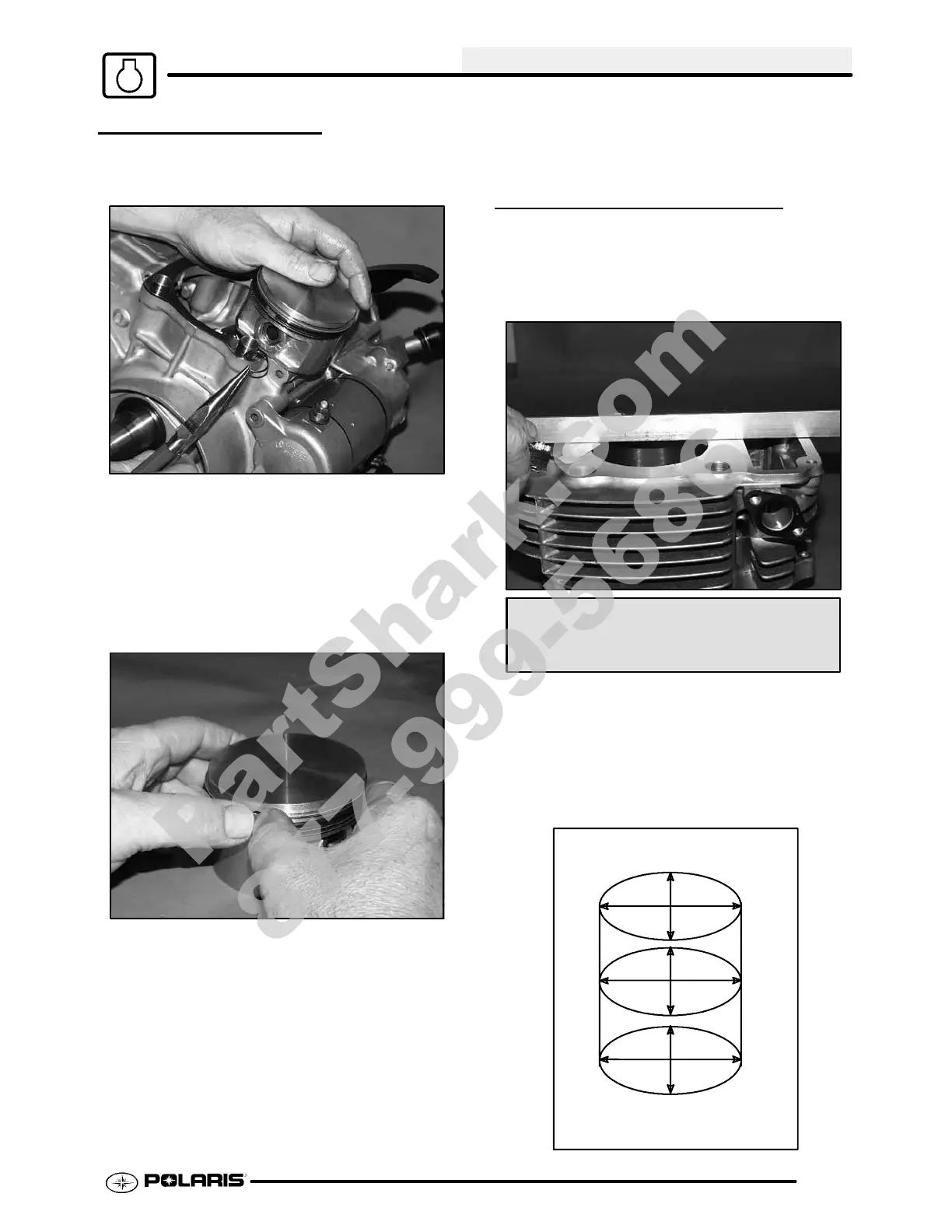

PISTON REMOV

AL

1. Remove circlip. Note that opening for circlip

access is on the intake side.

2. Remove piston circlip and push piston pin out of

piston. If necessary, heat the crownof the piston

slightly with a propane torch. CAUTION: Do not

apply heat to the piston rings. The ring may lose

radial tension.

3. Remove top compression ring.

*Using a piston ring pliers: Carefully expand ring

andliftit off thepiston. CAUTION: Donot expandthe

ring more than the amount necessary to remove it

from the piston, or the ring may break.

*Byhand: Placingboththumbsasshown, spreadthe

ring open and push up on the opposite side. Do not

scratch the ring lands.

4. Repeat procedure for second ring.

The oil control ring is a three piece design consisting

of a top and bottom steel rail and a center expander

section.

5. Remove the top rail first followed by the bottom

rail.

6. Remove the expander.

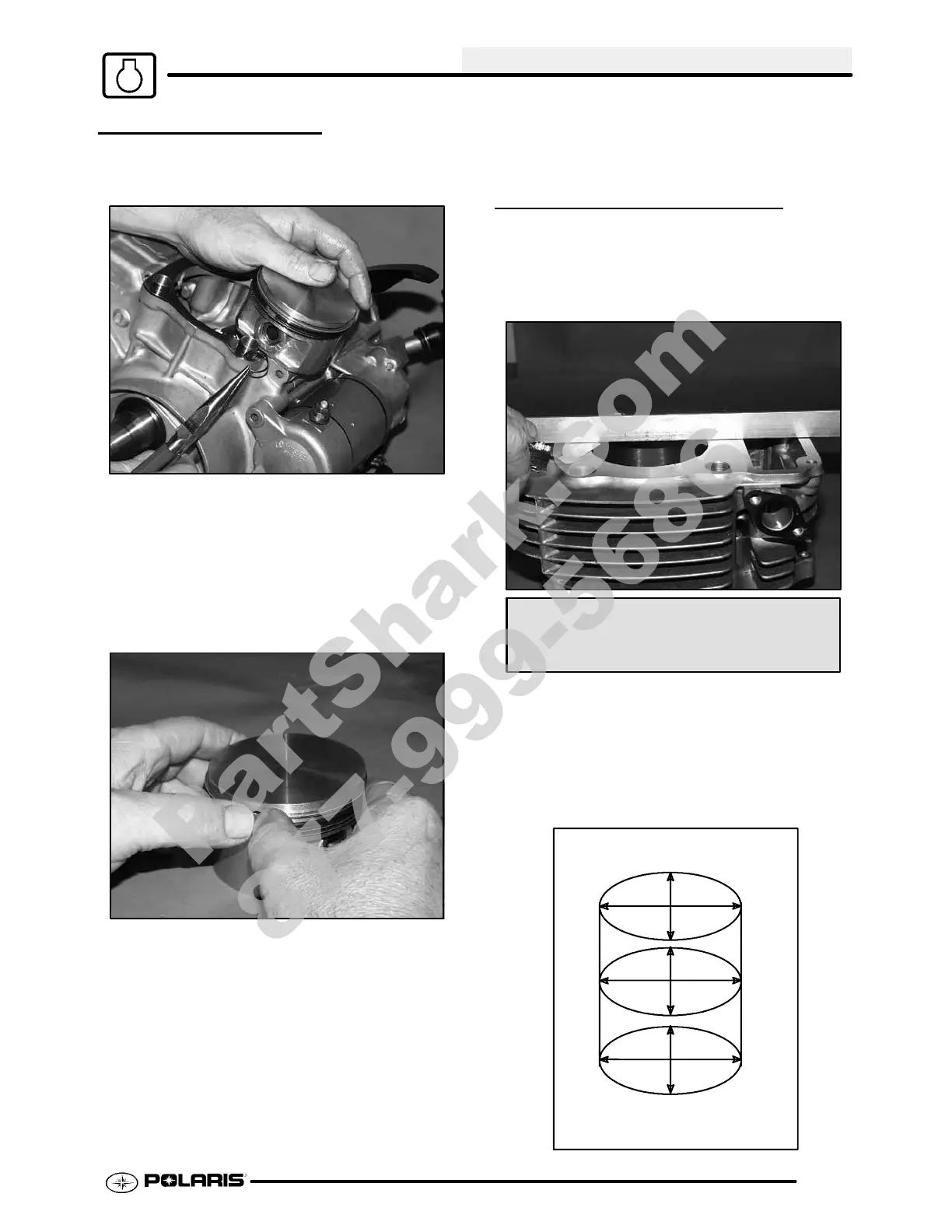

CYLINDER INSPECTION

1. Remove all gasket material from the cylinder

sealing surfaces.

2. Inspect thetopof thecylinderforwarpageusinga

straight edge and feeler gauge.

Cylinder Warpage:

.0020″ (.05 mm) MAX

3. Inspect cylinder for wear, scratches, or damage.

4. Inspect cylinder for taper and out of round with a

telescopinggaugeor adial boregauge. Measure

intwodifferentdirections,fronttobackandsideto

side, on threedifferentlevels(1/2″ downfromtop,

in the middle, and 1/2″ up from bottom).

1/2″ Down From Top of Cylinder

1/2″ Up From Bottom

X

X

Y

Y

X

Y

PartShark.com

877-999-5686

Loading...

Loading...