FUEL SYSTEM/CARBURETION

4.13

FLOAT HEIGHT

ADJUSTMENT

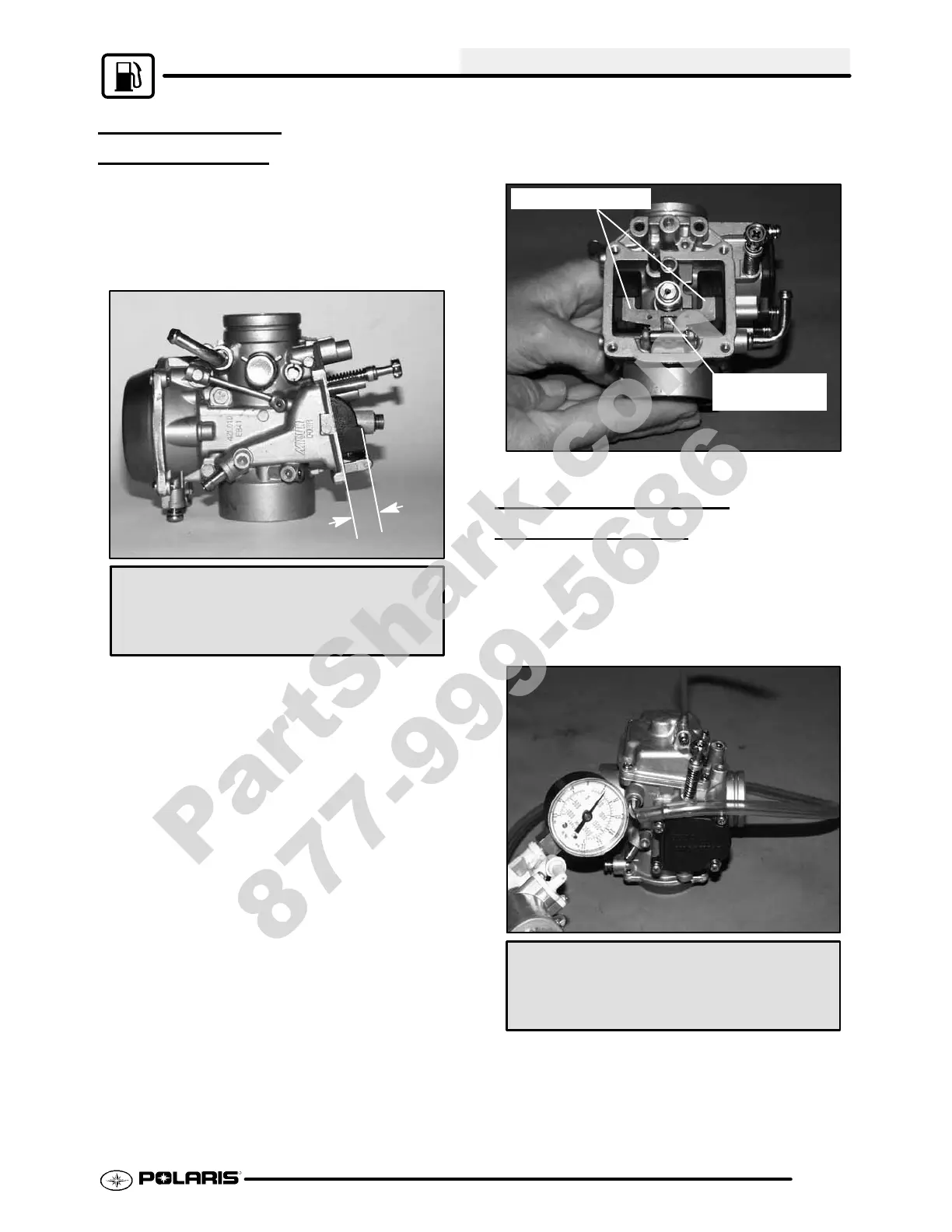

1. Place the carburetor on a level surface as shown

at right to remove weight from float arm. In this

position, the float tongue will rest lightly on the

inlet needle valve pin without compressing the

spring.

Float Height BST 34:

13--14 mm (.51--.55 inches)

2. Measure the height from the float bowl mating

surface to the top of step in float as shown. Both

sidesoffloat shouldbeparalleltoeachother. The

measurementshouldbemadeatthe mid-pointon

the top of the float using Float Adjustment Tool

(PN 2872314) or a vernier caliper. When

measuring the height be sure the inlet needle

valve spring is not compressed.

3. If adjustment is necessary, bend the tongue

slightly. Besurefloatmeasurementisevenonleft

and right side.

Bend to adjust

float

Float arms even

NEEDLE AND SEAT

LEAKAGE

TEST

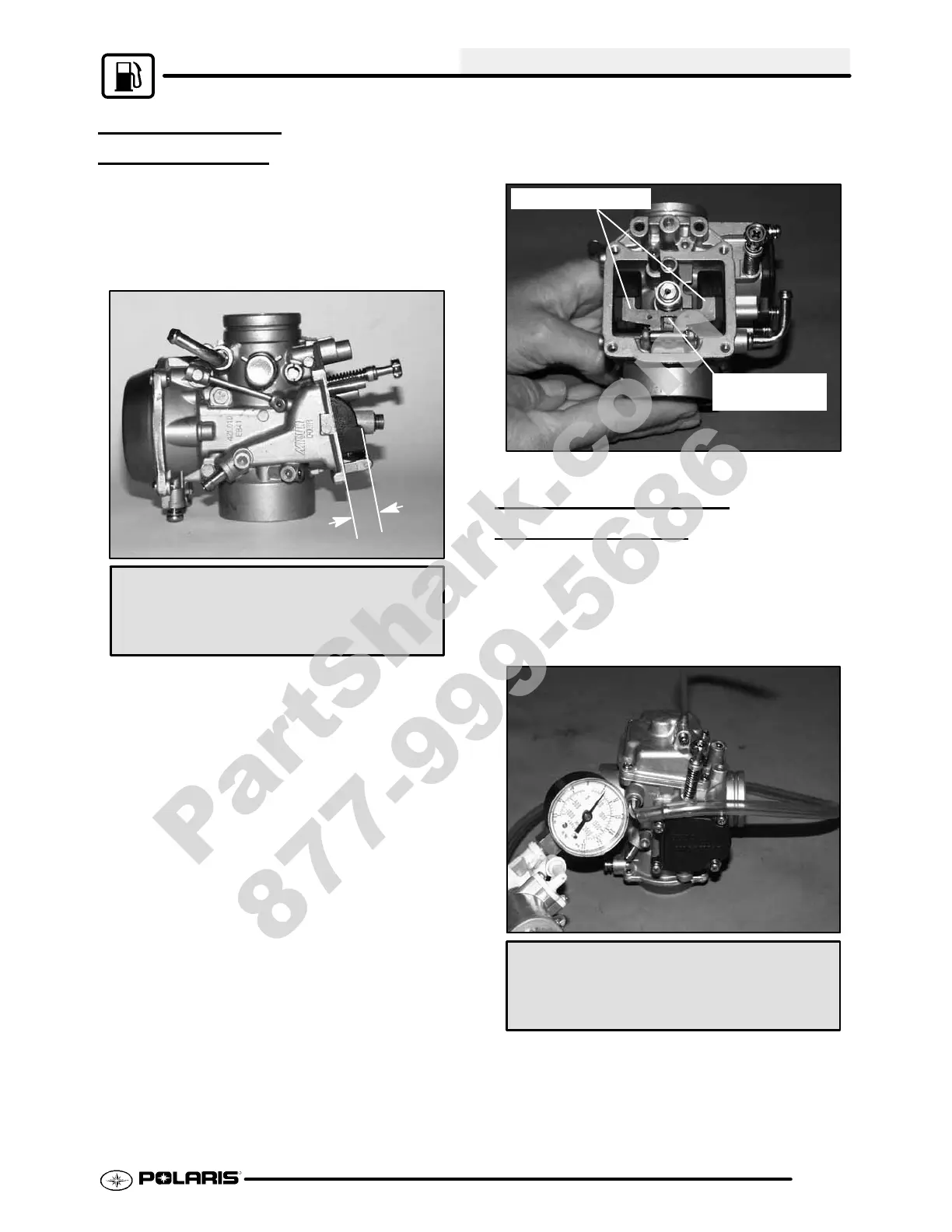

1. Install the float bowl. Invert the carburetor and

install a Mity-Vact (PN 2870975) to the fuelinlet

fitting. Apply 5 PSI pressure to inlet fitting. The

needleand seatshouldhold pressureindefinitely.

If not, inspect needle and seat and seat O-ring.

Mity Vact (PN 2870975)

PartShark.com

877-999-5686

Loading...

Loading...