CLUTCH

6.14

NOTE: At least one shim must remain between the

inner and outer sheave of the driven clutch. If proper

beltdeflectioncannot beobtained, measuredrive belt

width, length, and center distance of drive and driven

clutch, outlined in this section; all have an effect on

belt deflection.

DRIVE BELT

REMOV

AL/INSPECTION

1. Remove outer PVT cover as described in PVT

Disassembly.

2. Mark drive belt direction of rotation so that it can

be installed in the same direction. NOTE:

Normally positioned so part numbers are easily

read.

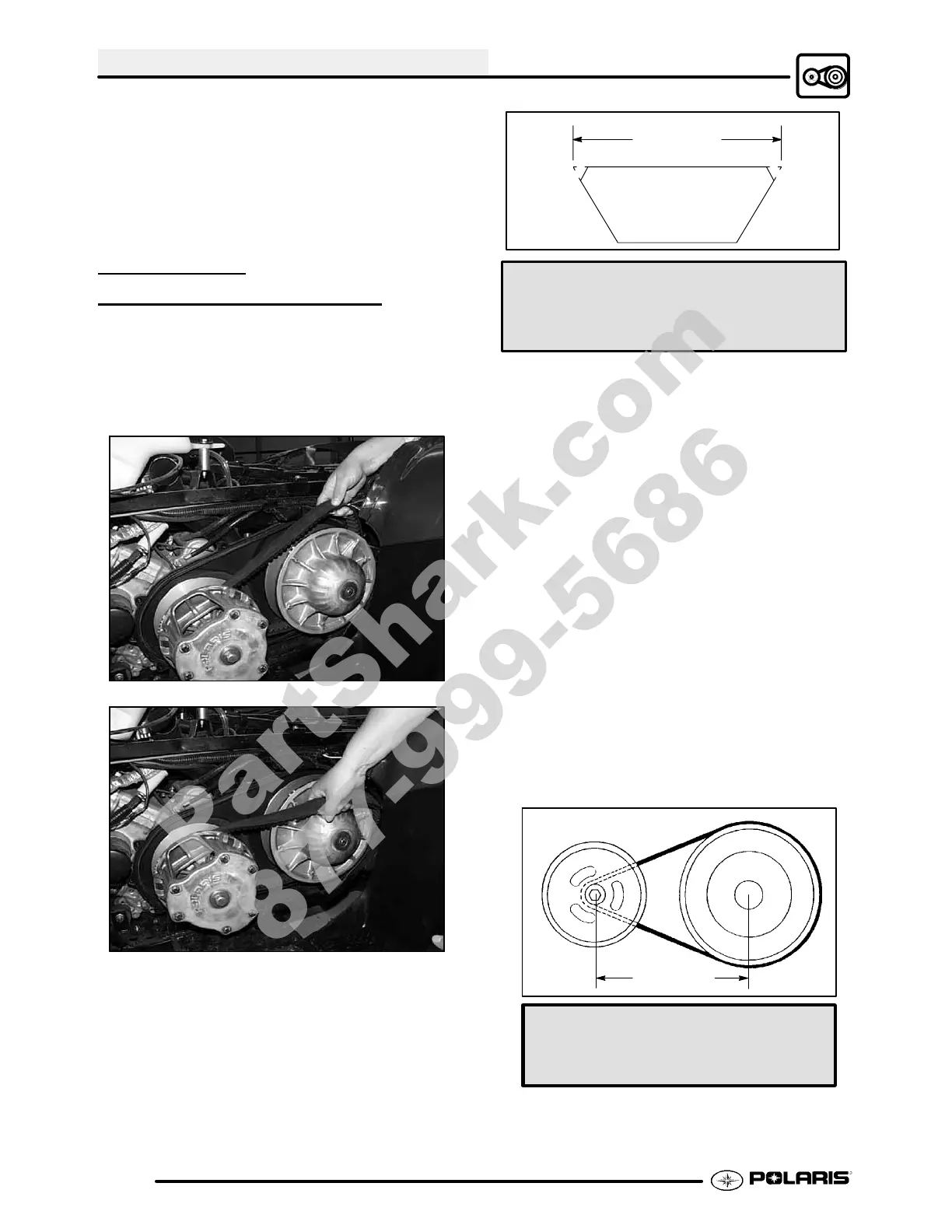

3. To remove drive belt: apply brake, pull upward

and rearward on belt to open driven clutch

sheaves, pullout anddownonbelt toslip over the

driven clutch outer sheave.

Projected

Belt

Width

Belt Width:

New 1.174 - 1.188″ (2.98-3.02 cm)

Wear Limit 1.125″ (2.86 cm)

4. Measure belt width and replace if worn severely.

Generally, belt should be replacedif clutches can

no longer be adjusted to provide proper belt

deflection.

G Thetopedgeshavebeentrimmedon

somedrivebelts. Itwillbenecessary

to project the side profiles and

measure from corner to corner.

G Placea straight edge oneachsideof

the drive belt.

G Placeanother straight edgeon topof

belt.

G Measurethedistancewhere theside

straight edges intersect the top, as

shown in the illustration below.

5. Inspectbeltforloosecords,missingcogs,cracks,

abrasions, thin spots, or excessive wear.

Replace if necessary.

6. Inspect belt for hour glassing (extreme circular

wear in at least one spot and on both sides of the

belt). Hour glassing occurs when the drive train

does not move and the drive clutch engages the

belt.

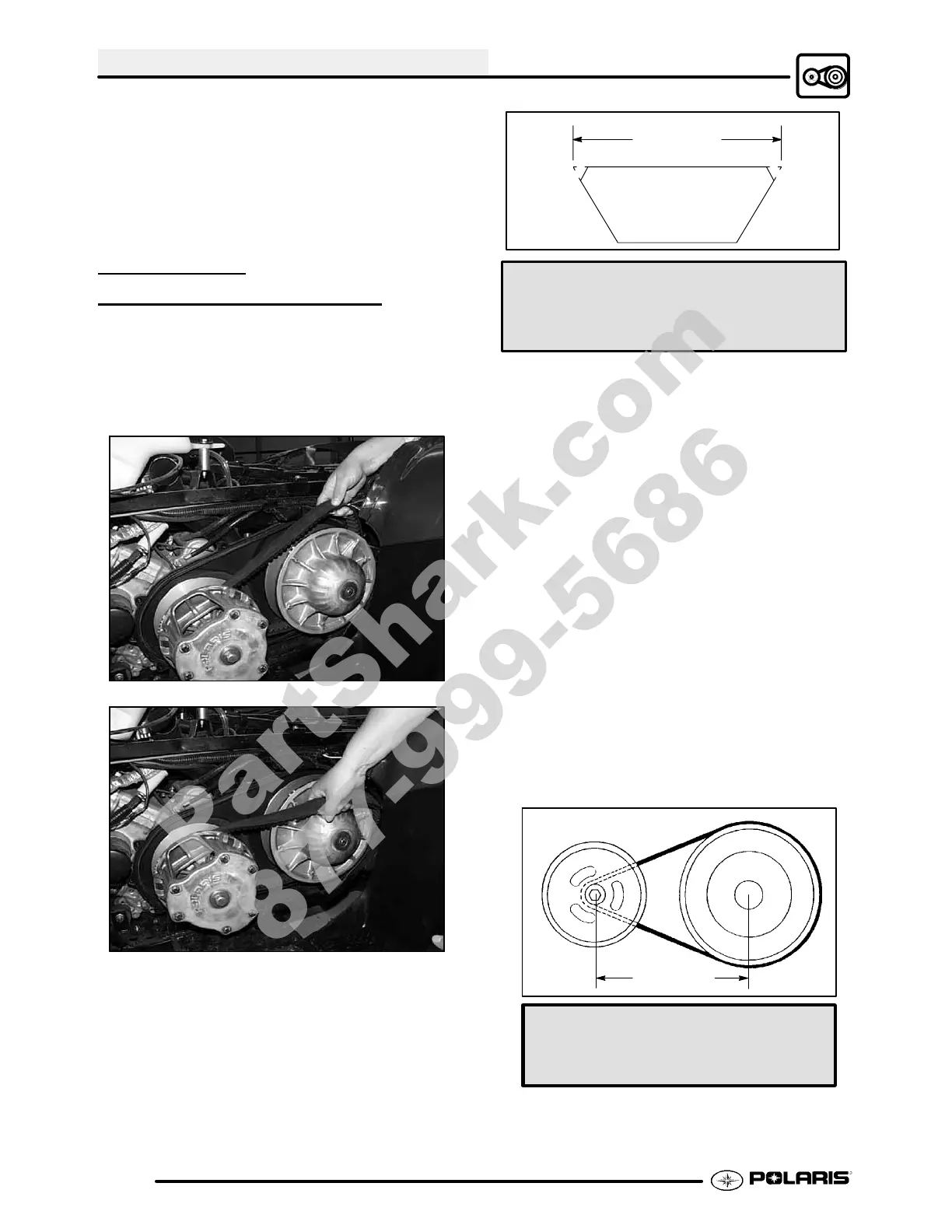

Center

Distance

Clutch Center Distance -

10″ +.1 / -.05 (254 +2.5 / -1.3mm)

Belt Nominal Length - 40.875″± 3/16

(103.8 cm ± .48 cm)

7. Measure belt length with a tape measure around

the outer circumference of the belt. Belts which

PartShark.com

877-999-5686

Loading...

Loading...