CLUTCH

6.20

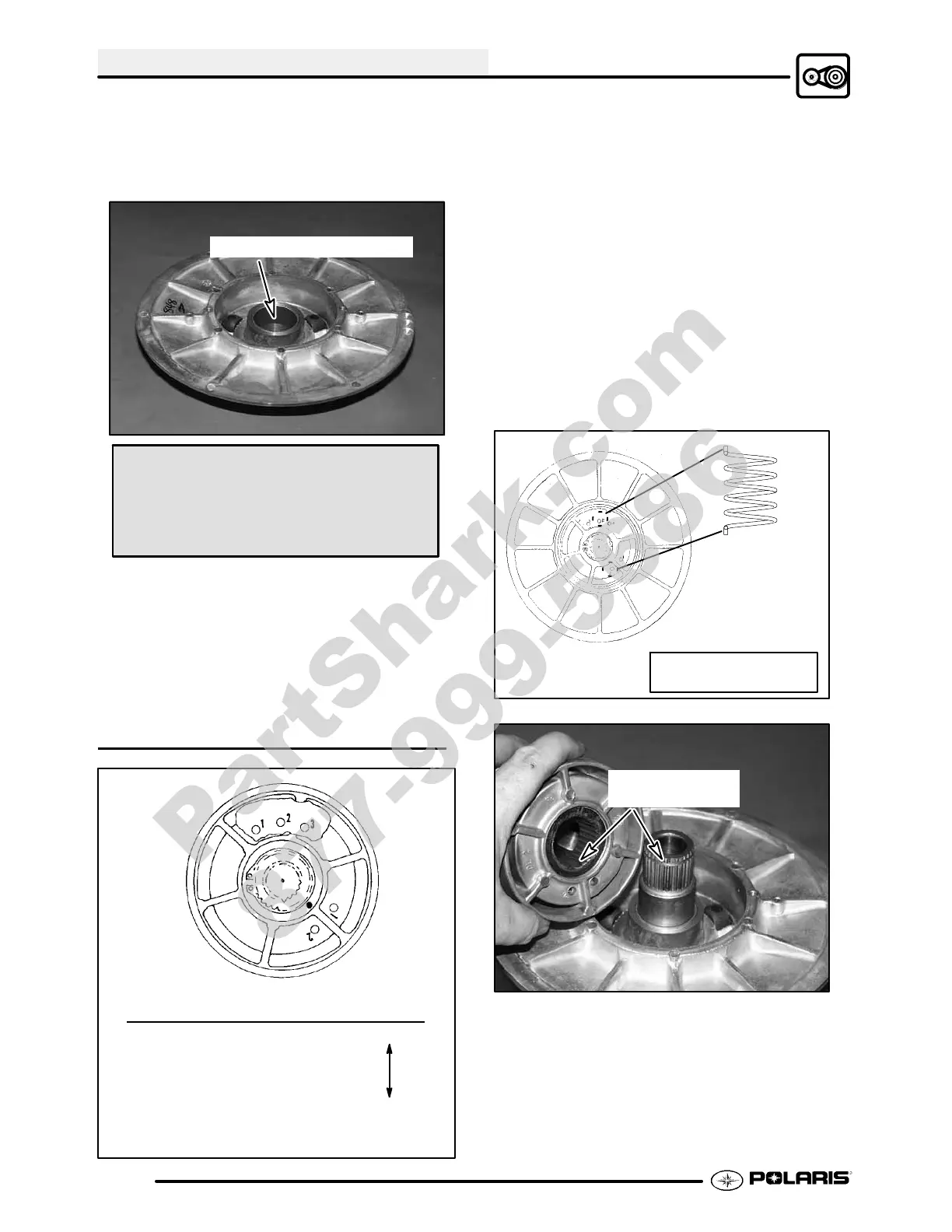

7. Remove moveable sheave and note the number

of spacer washers. One spacer must remain

between the sheaves when adjusting belt

deflection.

Inspect bushings for wear

Moveable Sheave Bushing Inspection:

Replace the bushing if more brass than

Teflont is visible on the bushing. Re-

fer to bushing replacement in this

chapter.

8. Inspect the Teflont coating on the moveable

sheave bushing.

9. Inspect driven clutch faces for wear or damage.

10. Clean and inspect splines on helix and

transmission input shaft.

11. Lube splines with a light film of grease. Do not

lubricate the bushings!

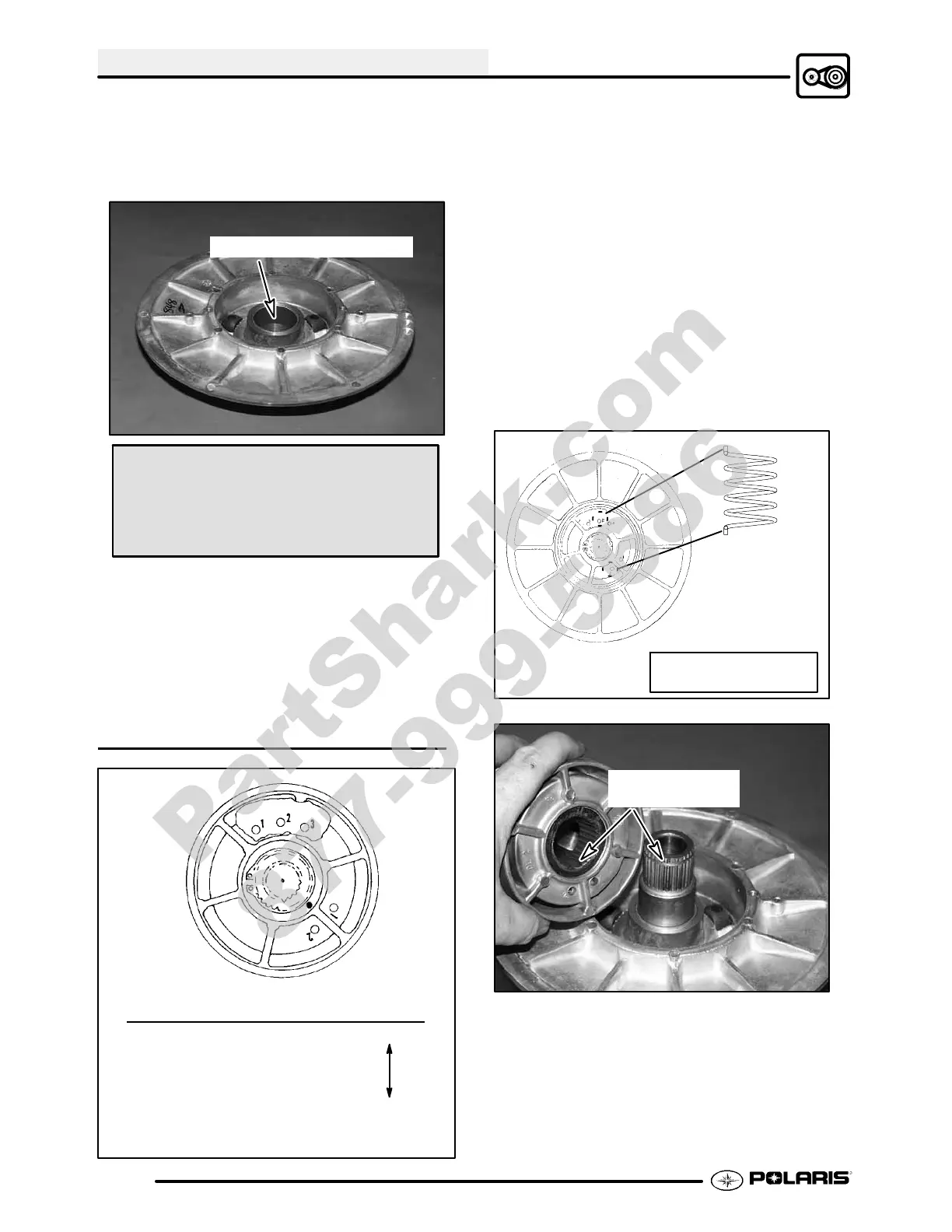

DRIVEN CLUTCH ASSEMBLY

Moveable Spring

Example: Helix Sheave Tension

2 -- 1 Heavy

Spring/ 2 -- 2

Position 1 -- 1

2--3

1--2

1--3 Soft

Refer to General Information Chapter 1 for driv-

en clutch spring color and production setting.

1. Install moveable sheave with spacer washers.

Important: At least one spacer washer must be

installed. Teflont bushings are self-lubricating.

Do not apply oil or grease to the bushings.

2. Install spring, inserting spring tabintoproperhole

in moveable sheave.

3. Insert spring tab into proper hole in helix. See

specifications Chapter 1 or Illustration 2 below.

The driven clutch, helix/moveable assembly has

several different spring locations which affect clutch

shifting and RPMs. The greatest amount of spring

tension will raise engine RPMs during clutch upshift

and allow quicker backshift or downshift when pulling

or negotiatinga hill, for example. Theleast amount of

tension will create a slower downshift and a harder

upshift.

Driven Clutch

Driven Spring

T railboss 330 Driven

Spring Placement: 2--2

Ill. 2

Align boss spline

to install helix

4. Line up boss spline and push helix down until it

engages the splines 1/2″ to 3/4″.

PartShark.com

877-999-5686

Loading...

Loading...