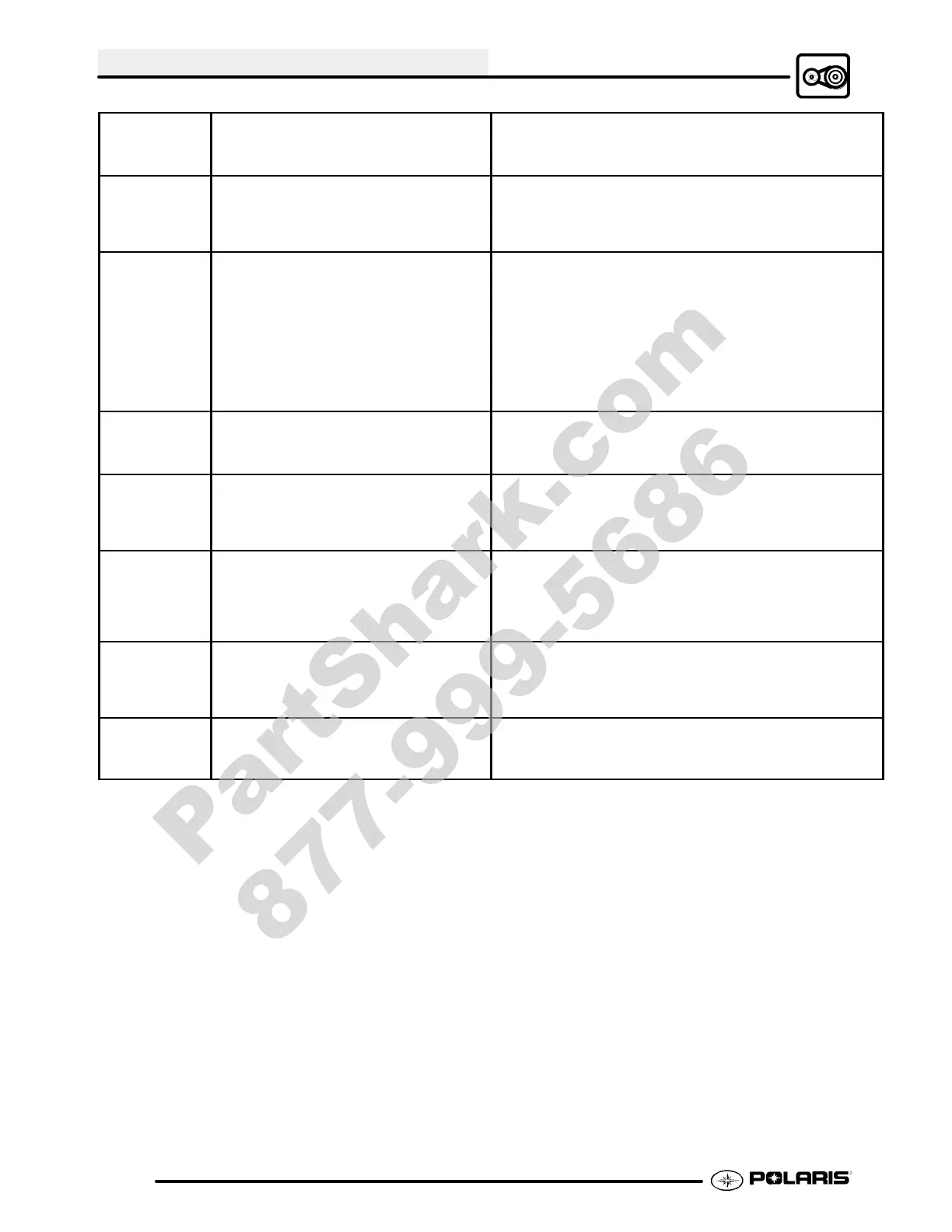

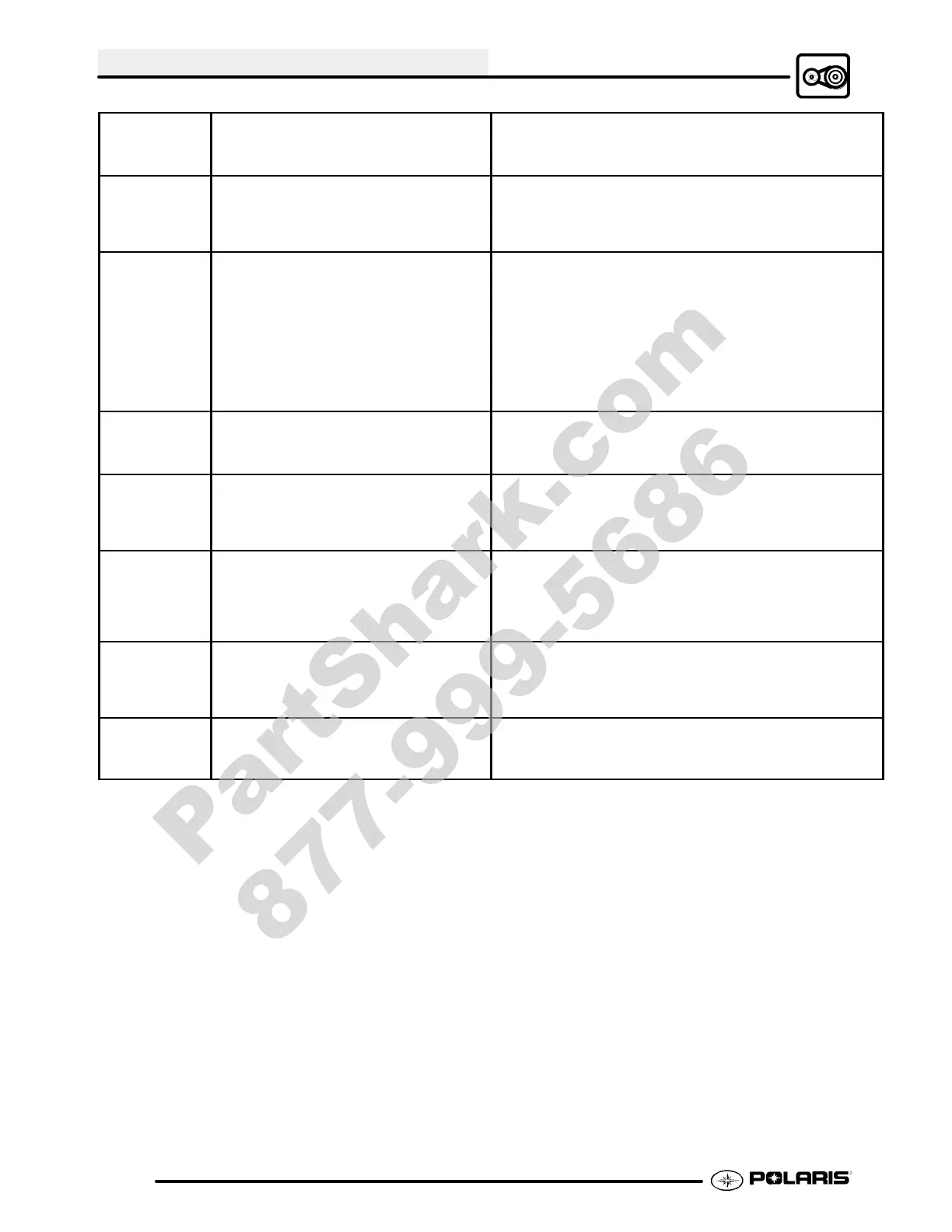

CLUTCH

6.24

Harsh drive

clutch engage-

ment.

-Drive belt worn too narrow.

-Excessive belt/s heave clearance with new

belt.

-Replace belt.

-Perform belt/sheave clearance adjustment with shim wash-

ers beneath spider.

Drive belt turns

over

-Wrong belt for application.

-Clutch alignment out of spec.

-Engine mount broken or loose.

-Replace with correct belt.

-Adjust alignment offset.

-Inspect/adjust or replace.

PVT cover

overheating

(melting)

-Plugged air intake or outlet

-Belt slippage due to water, oil, grease,

etc., rubbing on cover

-Clutches or weight being applied to cover

while in operation

-High vs. low range

-Clear obstruction.

-Inspect system. Clean , repair or replace as necessary.

Seal PVT system ducts.

-Remove weight. Inform operator.

-Instruct operator on guidelines for operation in proper driving

range for different terrain as outlined in Owner’s Safety and

Maintenance Manual.

Water ingestion -Cover seals or ducts leaking

-Operator error

-Find leak and repair as necessary.

-Instruct operator on guidelines for operation in wet terrain as

outlined in Owner’s Safety and Maintenance Manual.

Belt slippage -Belt worn out

-Water ingestion

-Belt contaminated with oil or grease

-Replace belt.

-Inspect and seal PVT system.

-Inspect and clean.

Belt burnt, thin

spots

-Abuse (continued throttle application when

vehicle is stationary, excess load)

-Dragging brake

-Slow, easy clutch engagement

-Caution operator to operate machine within guidelines.

-Vehicle operated with park brake on. Inspect brake system.

-Fast, effective use of throttle for efficient engagement.

PVT noise -Belt worn or separated, thin spots, loose

belt

-Broken or worn clutch components, cover

hitting clutches

-Replace belt.

-Inspect and repair as necessary.

Engagement

erratic or stabby

-Thin spots on belt, worn belt

-Drive clutch bushings stick

-Replace belt. Refer to belt burnt troubleshooting and instruct

operator.

-Inspect and repair clutches.

PartShark.com

877-999-5686

Loading...

Loading...