RH850/F1Kx, RH850/F1K Series Hardware Design Guide

R01AN3841ED0110 Rev. 1.10 Page 103 of 108

August 8, 2019

8.4 Debug Considerations when Hot Plug-in is used

When it is planned to use the hot plug-in function for debugging the following topics should be considered.

RESET

pin

When the hot plug-in will be used it is recommended to consider the installation of a capacitor between the reset signal

and GND in order to suppress a noise. In this case, the time constant of the reset circuit shall be adjusted that the time

elapsing before the signal reaches 80% of the high level from the low level is within 900 µs.

Power source monitoring

When the hot plug-in function will be used it is recommended to configure the external circuit of the power source

monitoring at pin 8 (TVDD) of the E1/E2 emulator connector with a ferrite bead or inductor. This additional ferrite

bead or inductor is recommended to avoid a momentary drop in the power-supply voltage on the user system that could

lead to a reset of the microcontroller.

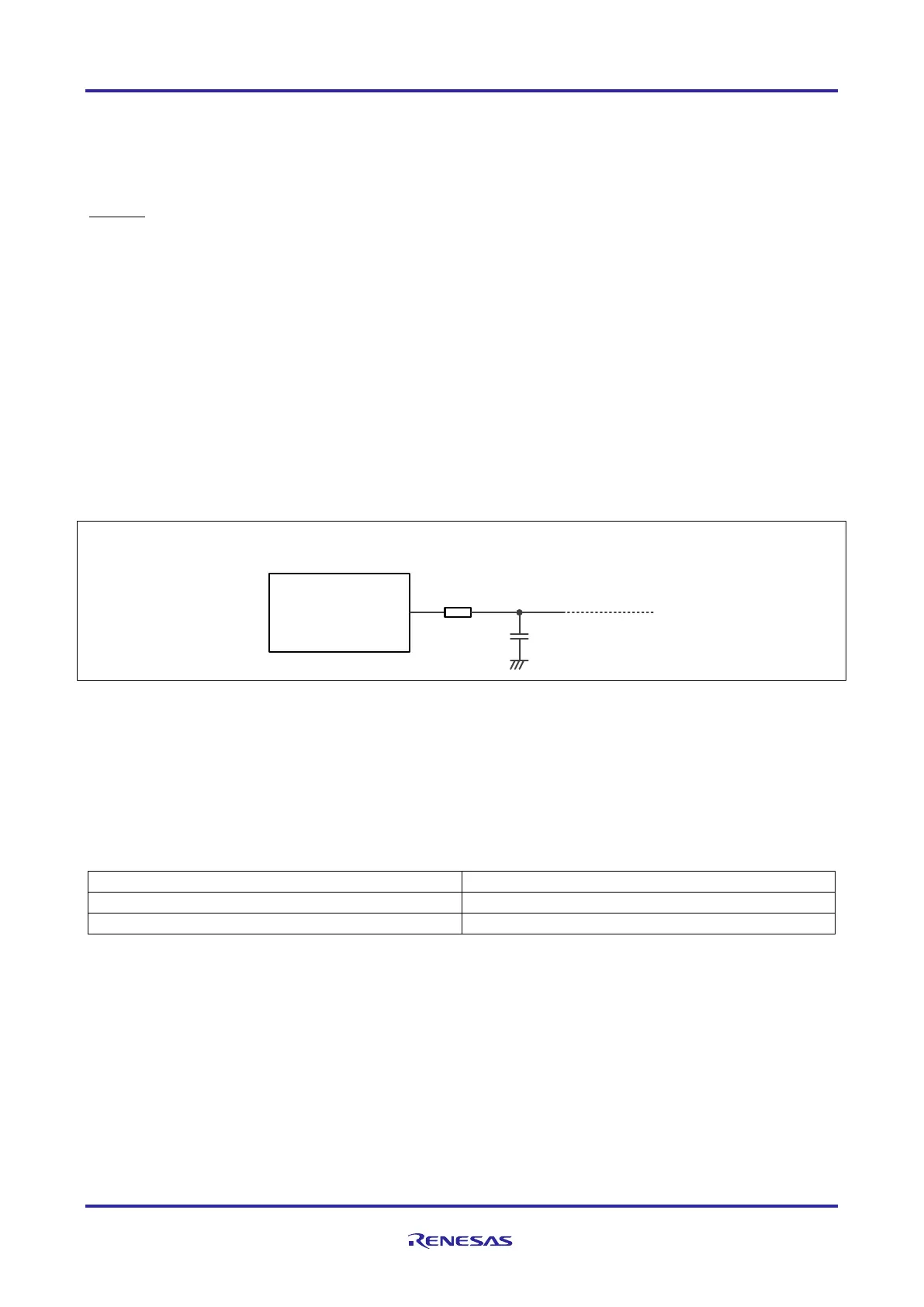

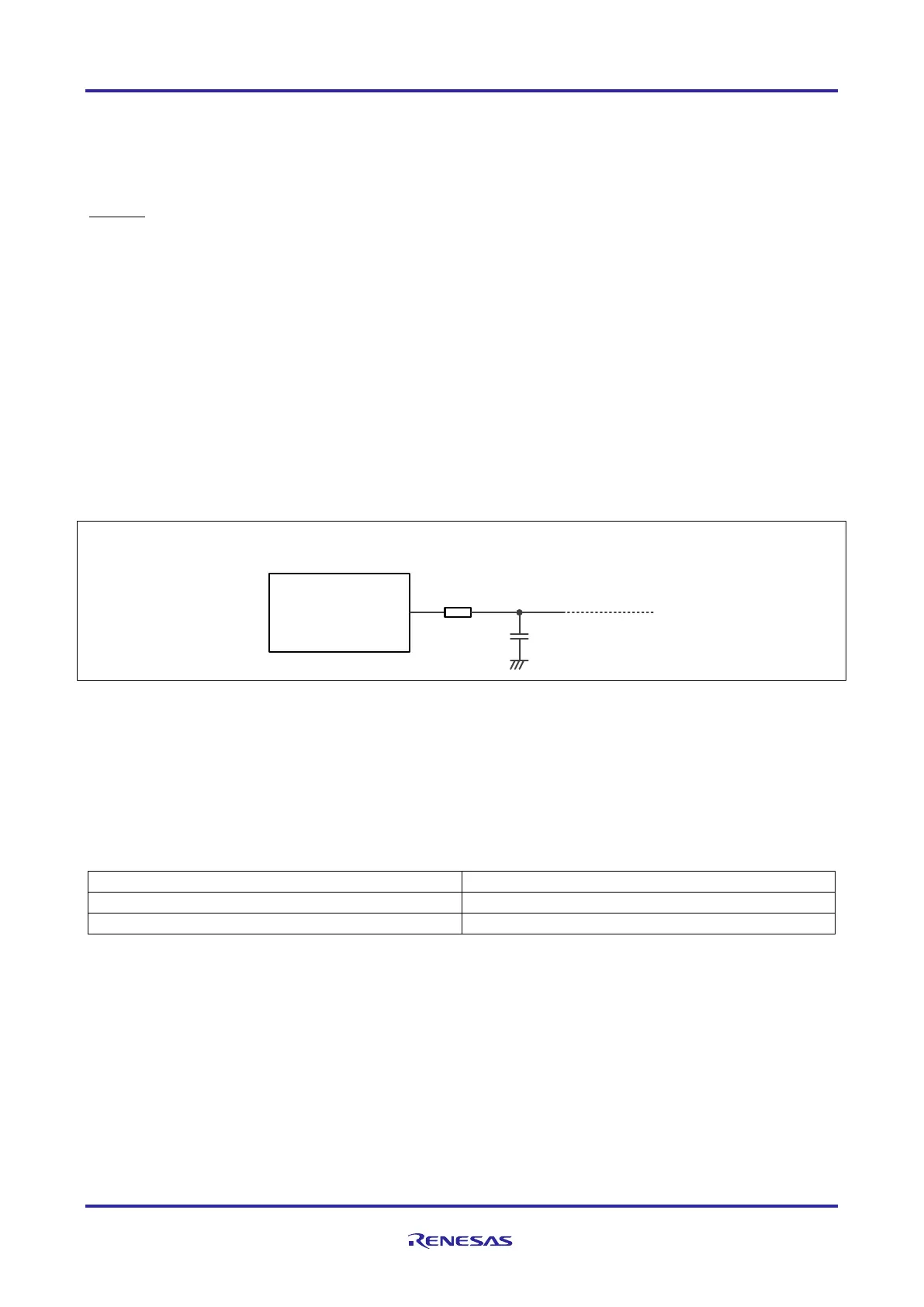

This effect can be reduced as shown in Figure 22 by placing a ferrite bead (or inductor) L1 and an additional capacitor

C1 near the TVDD line of the connector for the E1/E2 emulator.

Figure 44: Circuit configuration for hot plug-in

Note: This measure might not eliminate completely the voltage drop.

General guidance for the additional external components for the power source monitoring during hot plug-in:

Table 74: Basic component value for hot plug-in

The value of the capacitor C1 and the inductor/ferrite bead L1 depends on the application requirements.

TVDD

E1/E2 Emulator

(14pin Connector)

C1

8

L1

Loading...

Loading...