8. PARAMETER DESCRIPTION

IMR02C15-E4

8-109

Control loop break alarm (LBA)

The Control loop break alarm (LBA) function is used to detect a load (heater) break or a failure in the

external actuator (power controller, magnet relay, etc.), or a failure in the control loop caused by an

input (sensor) break.

The LBA function is activated when control output reaches 0 % (low limit with output limit function)

or 100 % (high limit with output limit function). LBA monitors variation of the Measured value (PV)

for the length of LBA time. When the LBA time has elapsed and the PV is still within the alarm

determination range, the LBA will be ON.

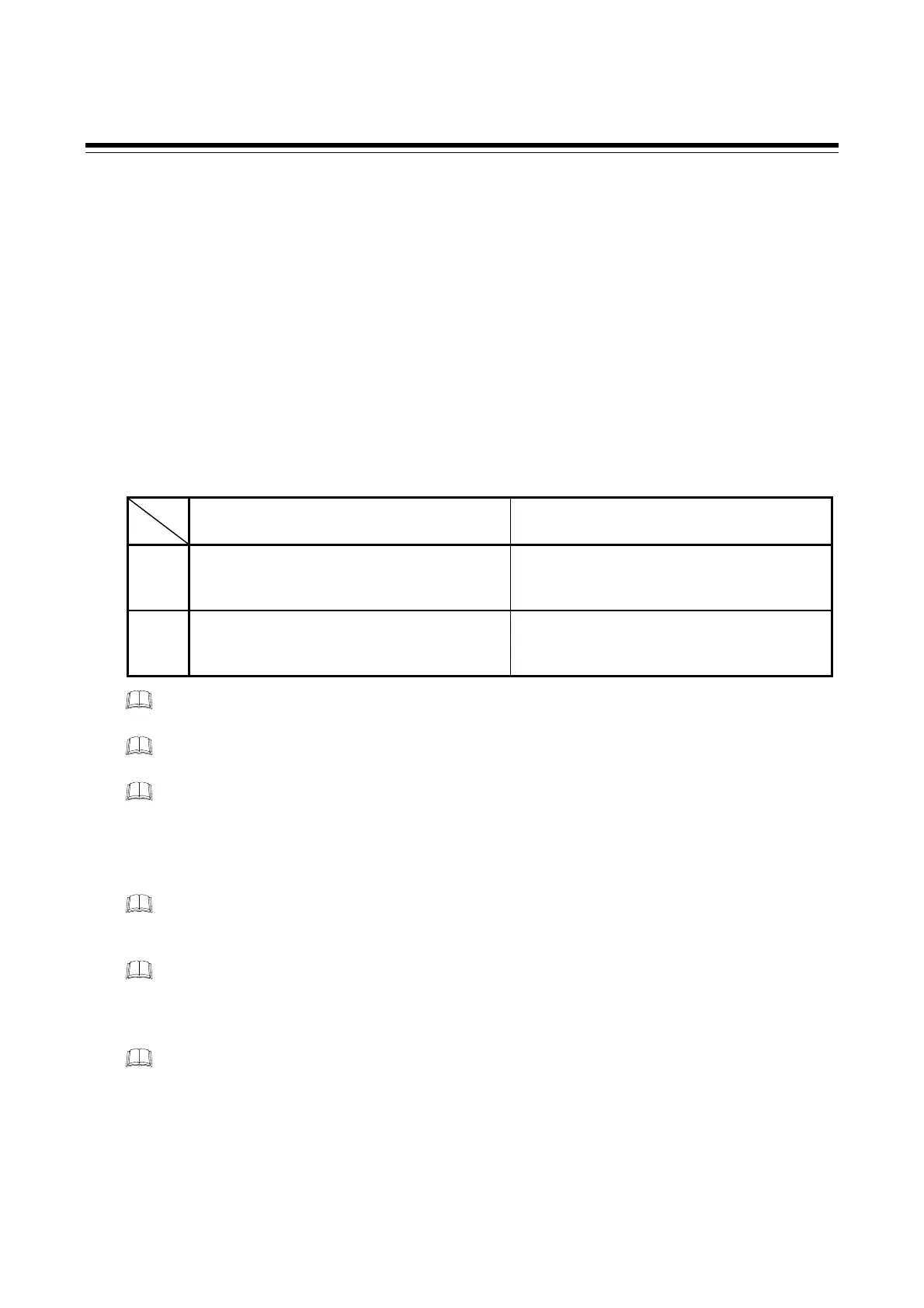

[Alarm action]

LBA determination range: Thermocouple/RTD input: 2 °C [°F] (fixed)

Voltage/Current input: 0.2 % of span (fixed)

Heat control

When the output reaches 0 %

(low limit with output limit function)

When the output exceeds 100 %

(high limit with output limit function)

For

reverse

action

When the LBA time has passed and the PV

has not fallen below the alarm determination

range, the alarm will be turned on.

When the LBA time has passed and the PV

has not risen beyond the alarm determination

range, the alarm will be turned on.

For

direct

action

When the LBA time has passed and the PV

has not risen beyond the alarm determination

range, the alarm will be turned on.

When the LBA time has passed and the PV

has not risen beyond the alarm determination

range, the alarm will be turned on.

If the Autotuning function is used, the LBA time is automatically set twice as large as the

Integral time. The LBA setting time will not be changed even if the Integral time is changed.

Normally the LBA time of Parameter setting mode should be set to approximately twice the

Integral time.

LBA function is not operative when:

• When AT function is activated.

• When the controller is in STOP mode.

• LBA time is set to “0.”

• LBA function is not assigned to Event 1 (ES1) to Event 4 (ES4).

If the LBA time is too short or does not match the controlled object requirements, LBA may

turn ON or OFF at inappropriate time or remain OFF. Change the LBA time based on the

malfunction.

If the LBA function detects an error occurring in the control loop, but cannot specify the

location, the control loop should be checked. The LBA function does not detect the location

which causes alarm status. If LBA alarm is ON, check each device or wiring in the control

loop.

While the LBA is ON (under alarm status), the following conditions will cancel the alarm

status and LBA will be OFF:

• The Measured value (PV) rises beyond (or falls below) the LBA determination range

within the LBA time.

• The Measured value (PV) enters within the LBA deadband.

Loading...

Loading...