4–12 Component Test Procedures

Publication 1336 IMPACT-6.8 – November, 2002

3. If either diode is out of tolerance, refer to Replacing Volt-Sharing

Resistors and Dual Diodes in Chapter 5, Part Replacement

Procedures.

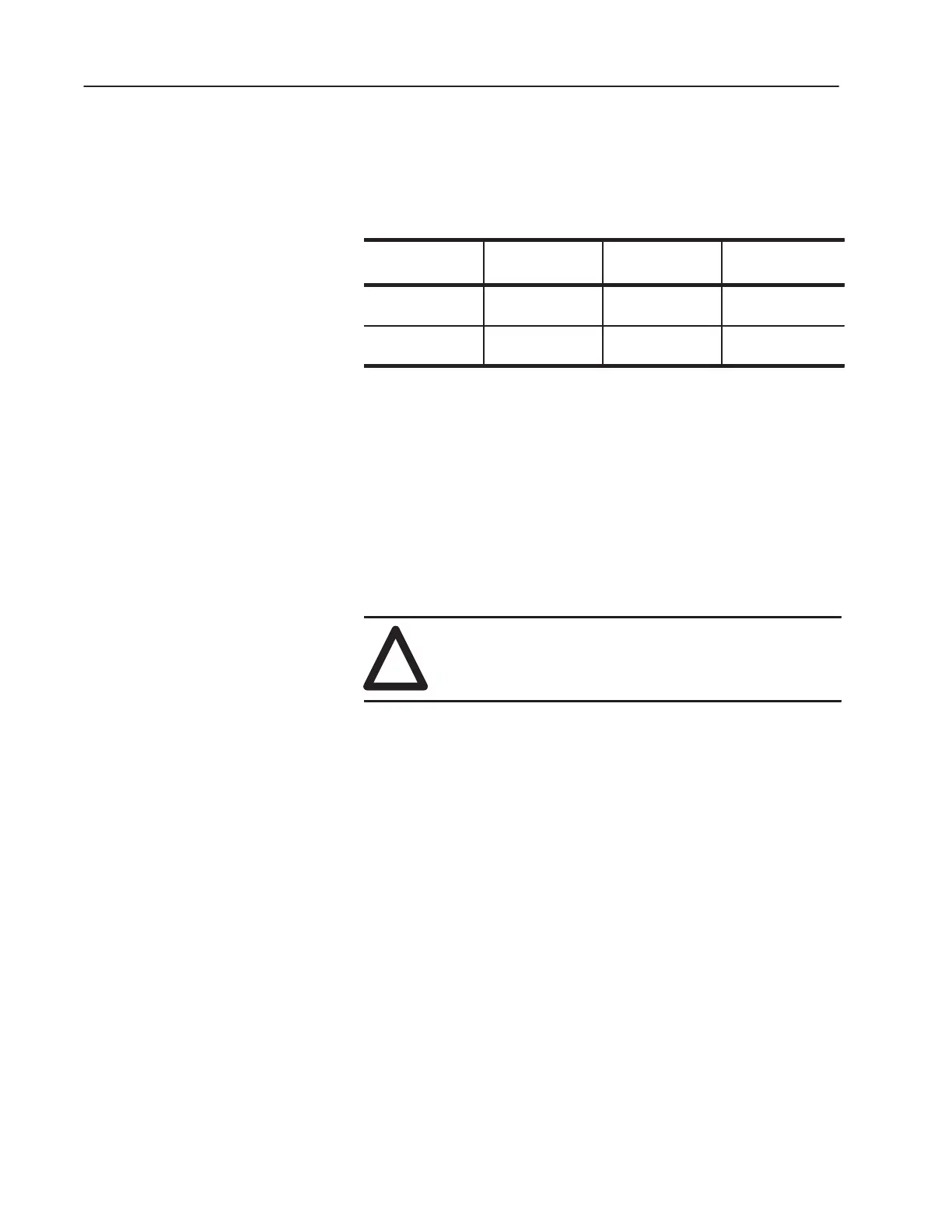

Table 4.E

Dual Diode Test

Component

Meter (+)

Lead

Meter (–)

Lead

Nominal Meter

Reading*

D1

Top

Bottom

Bottom

Top

Less than 1

Open

D2

Top

Bottom

Bottom

Top

Less than 1

Open

Note: Typical malfunction is shorted in both directions.

* Meter Used: Fluke

Model 87, set to “Diode” range.

Important: There is no diode on F3.

Capacitor Test

The only practical test for these capacitors is to look for signs of

damage: swelling, leaking, or burn marks. To replace the Bus

Capacitors, refer to Replacing Bus Capacitors in Chapter 5, Part

Replacement Procedures.

!

ATTENTION: Replace all guards before applying

power to the drive. Failure to replace guards may result

in death or serious injury.

Loading...

Loading...