158 Rockwell Automation Publication 750-TG100B-EN-P - June 2019

Chapter 7 Control Bay and Control Pod Components

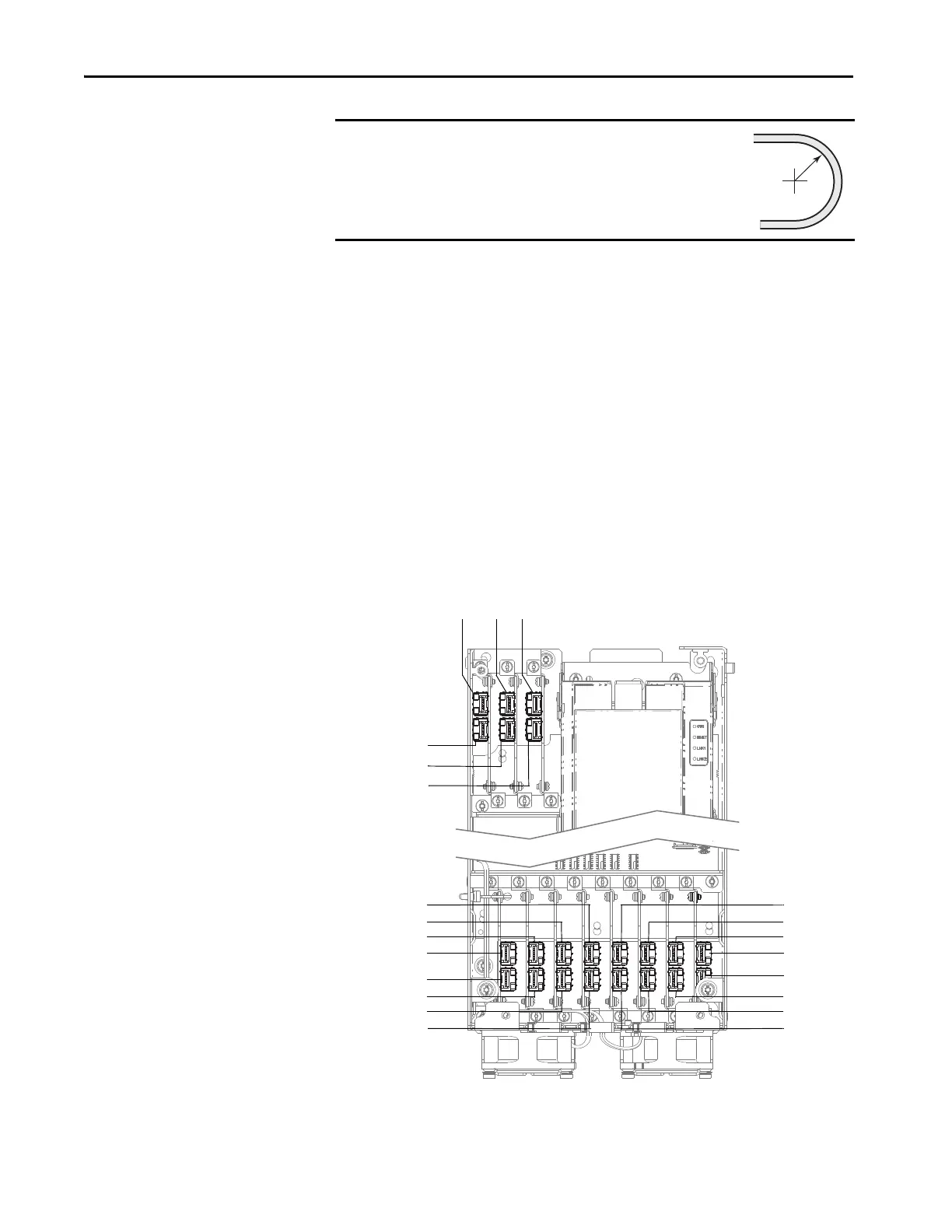

8. Remove the fiber-optic cables from the cable management devices in the

control pod.

9. Disconnect the AC precharge circuit board and torque accuracy module

fiber-optic cables from the ACP0 and ACPC1/TAM port on the fiber

transceiver board, respectively. Carefully coil the fiber-optic cable and

secure in a protected location. Follow the minimum bend radius

requirement.

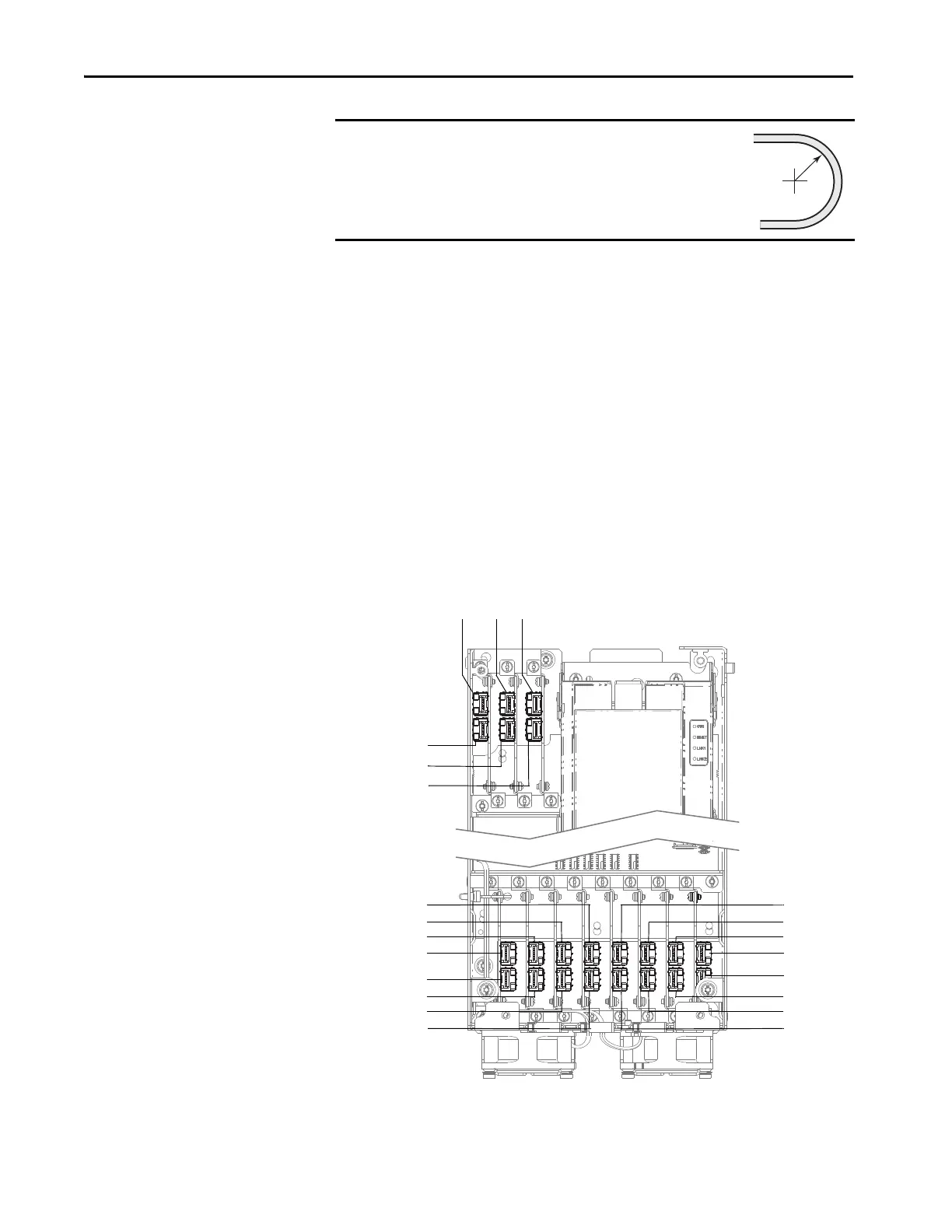

10. For each line side inverter, disconnect the fiber-optic cable from the Ln

port on the fiber transceiver board. Carefully coil the fiber-optic cable and

secure in a protected location. Follow the minimum bend radius

requirement.

11. For each motor side converter, disconnect the fiber-optic cable from the

Mn port on the fiber transceiver board. Carefully coil the fiber-optic cable

and secure in a protected location. Follow the minimum bend radius

requirement.

IMPORTANT

Minimum inside bend radius for fiber-optic cable is 50 mm

(2 in.). Any bends with a shorter inside radius can

permanently damage the fiber-optic cable. Signal

attenuation increases as inside bend radius is decreased.

ACP0 L0 L1

ACP1 / TAM

M0

M1

L8

L6

L4

L2

L9

L7

L5

L3

M2

M4

M6

M8

M3

M5

M7

M9

Loading...

Loading...