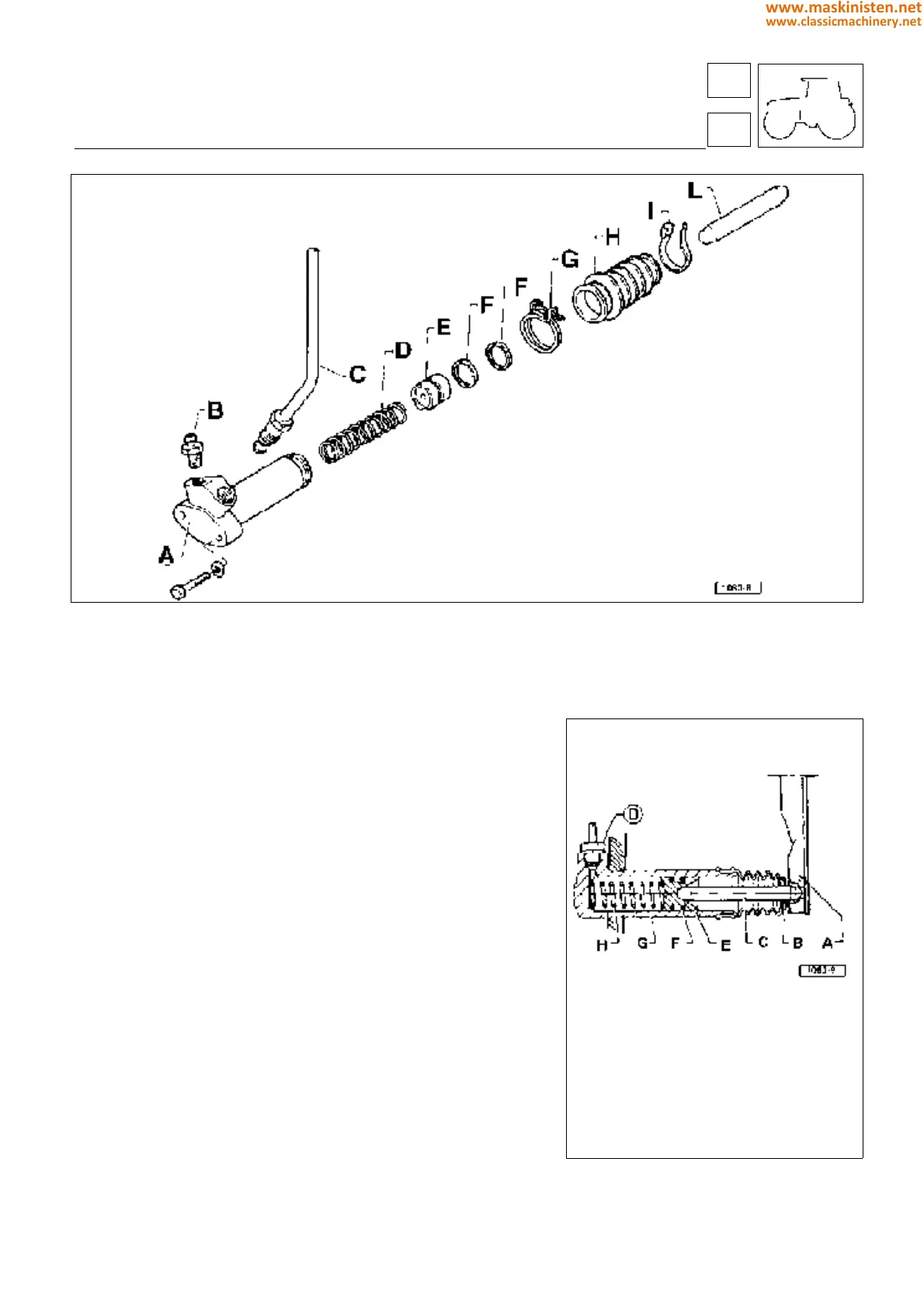

Fig. 11 - Clutch operating cylinder.

Stripping the slave cylinder (Fig 11)

Loosen the clip G and remove together with the boot H. Withdraw

the piston carefully from the cylinder, blasting with compressed air

at low pressure to assist removal. Remove the spring D from the

cylinder and loosen the bleed screw B.

Remove the seals F fom the piston E.

CAUTION: When cleaning the components of the cylinder, use

only specifically formulated brake and clutch fluids (see page 110).

Do not use petrol, paraffin or other mineral oils as these will

damage parts in rubber.

Inspections

— Check both internal and external piston surfaces for scratching.

Replace if required.

— Make sure the seal ring grooves are duly clean; blow the

grooves with compressed air if necessary.

— Inspect seal ring, dust boot conditions as well as spring effi-

ciency, worn-out parts should be replaced.

— Ensure the air bleeding hole is free from impurities.

Notes on refitment

— When reconnecting the transmission housing, check that the clutch

fork remains correctly positioned and free to rock on its fulcrum pivot.

This can be ensured by removing the side plug from the flange of the

intermediate housing and viewing the fork through the hole. In the event

of the fork pivot being unseated, reposition correctly with the aid of a

screwdriver inserted through the hole vacated by the plug.

— Before refitting the slave cylinder, fill with the recommended oil so

as to facilitate the subsequent bleeding procedure.

— Once all components are correctly and securely in place, bleed the

hydraulic circuit.

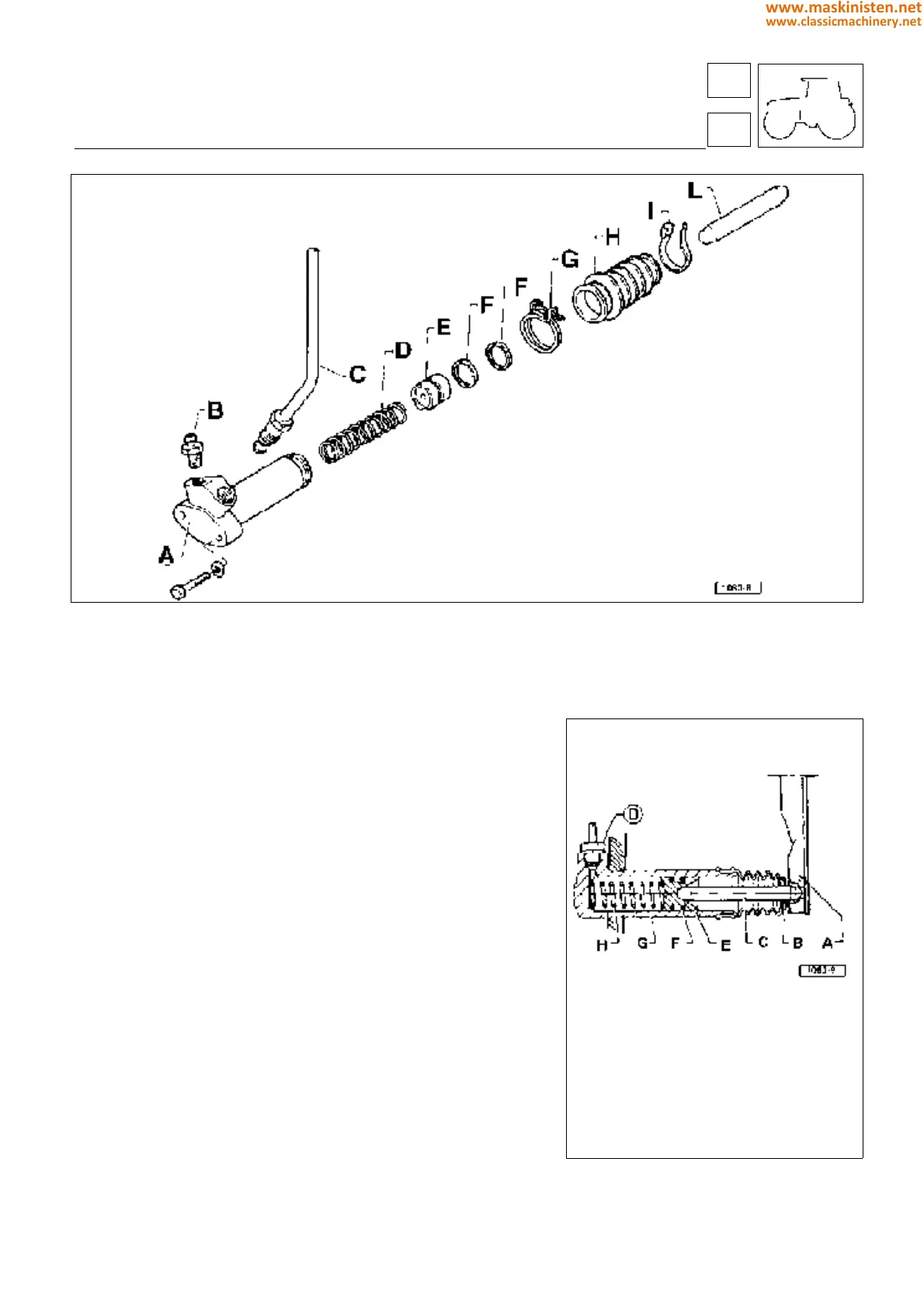

Fig. 12 - Clutch operating cylinder cutaway view.

clutch and transmission

clutch

A - Operating cylinder casing

B - Air bleeding screw plug

C - Supply pipe union

D - Spring

E - Piston

F - Seal ring

G - Clamp

H - Dust boot

I - Clamp

L - Pushrod

A - Control lever

B - Dust boot

C - Pushrod

D - Piston

E - Seal ring

F - Cylinder casing

G - Spring

H - Union

23

2

115

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...