Inspections and checks

WARNING: To clean and wash the hydraulic pump components

use only the oil type recommended for brakes and clutch (see

page 106). Never use petrol, kerosene or other mineral oils to

prevent damaging the rubber parts.

Inspect both internal and external piston sliding surfaces for

scratching. Replace if required.

Make sure the seal ring grooves are duly clean; blow the grooves

with compressed air if necessary.

Inspect seal ring, dust boot conditions as well as spring efficiency,

worn-out parts should be replaced.

Inspect all pump internal compartments, apertures and passages

and make sure these are properly clean and free from foreign

matters.

Check that the spring is neither lazy nor deformed; replace if

necessary.

Reassembly

Reassemble the cylinder, repeating the disassembly steps in reverse order and observing the following directions:

— Lubricate surfaces engaged in relative sliding contact, using the recommended oil (see page 110).

— Verify correct operation of the cylinder, making certain that the piston is able to complete its full stroke unimpeded.

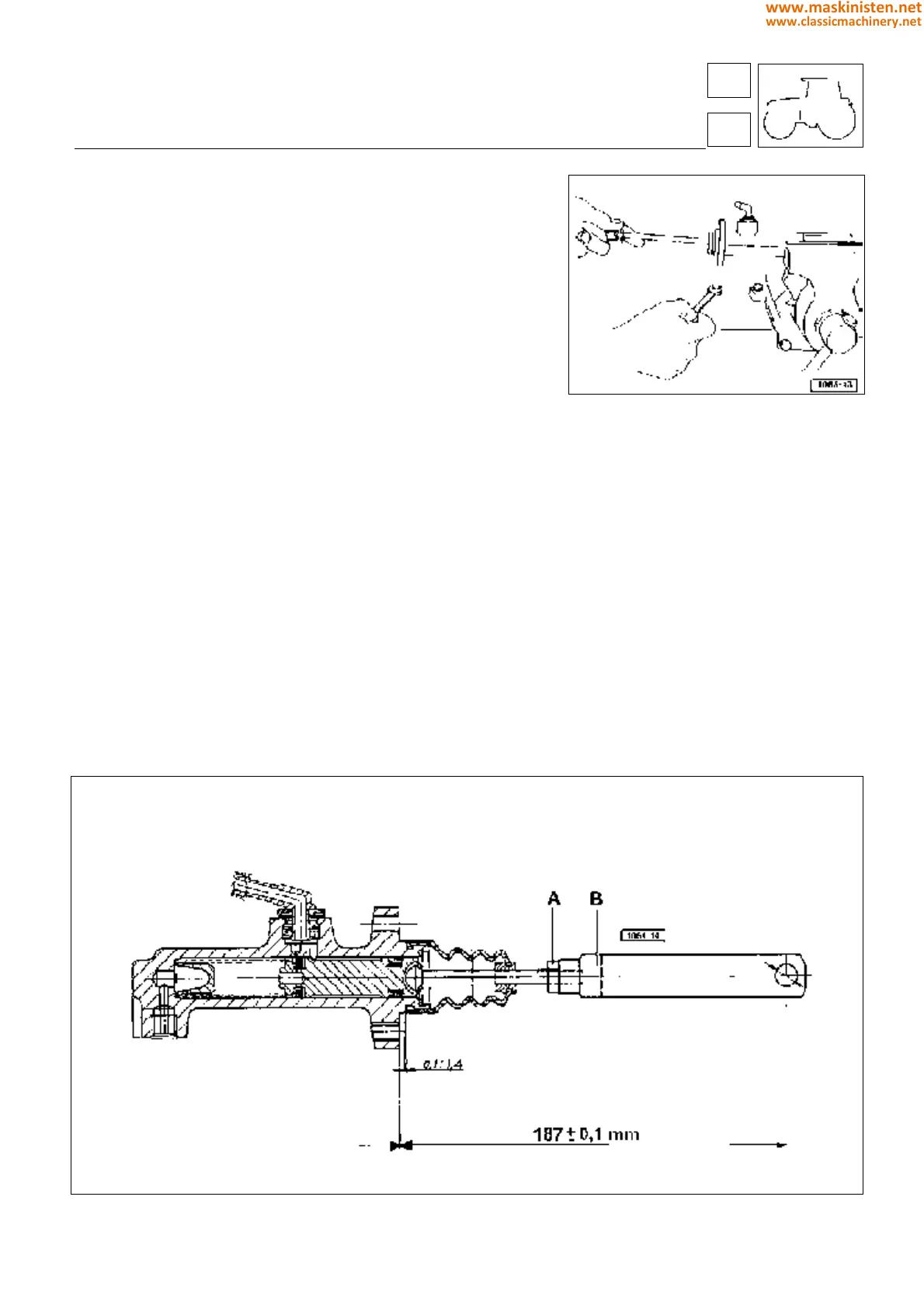

In the event that the fork linking the master cylinder with the pedal has been removed, check that with the push rod

fully extended, the distance between the reference surface of the cylinder and the centre of the hole in the fork is as

indicated in figure 17.

If not (referring to fig 14), remove the boot, loosen the lock nut A and screw or unscrew the fork B to obtain the prescribed

clearance, then retighten the lock nut and reposition the boot.

Fig 17 - Section through clutch master cylinder.

Fig. 16 - Removing the oil pump inside parts.

clutch and transmission

clutch

23

2

117

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...