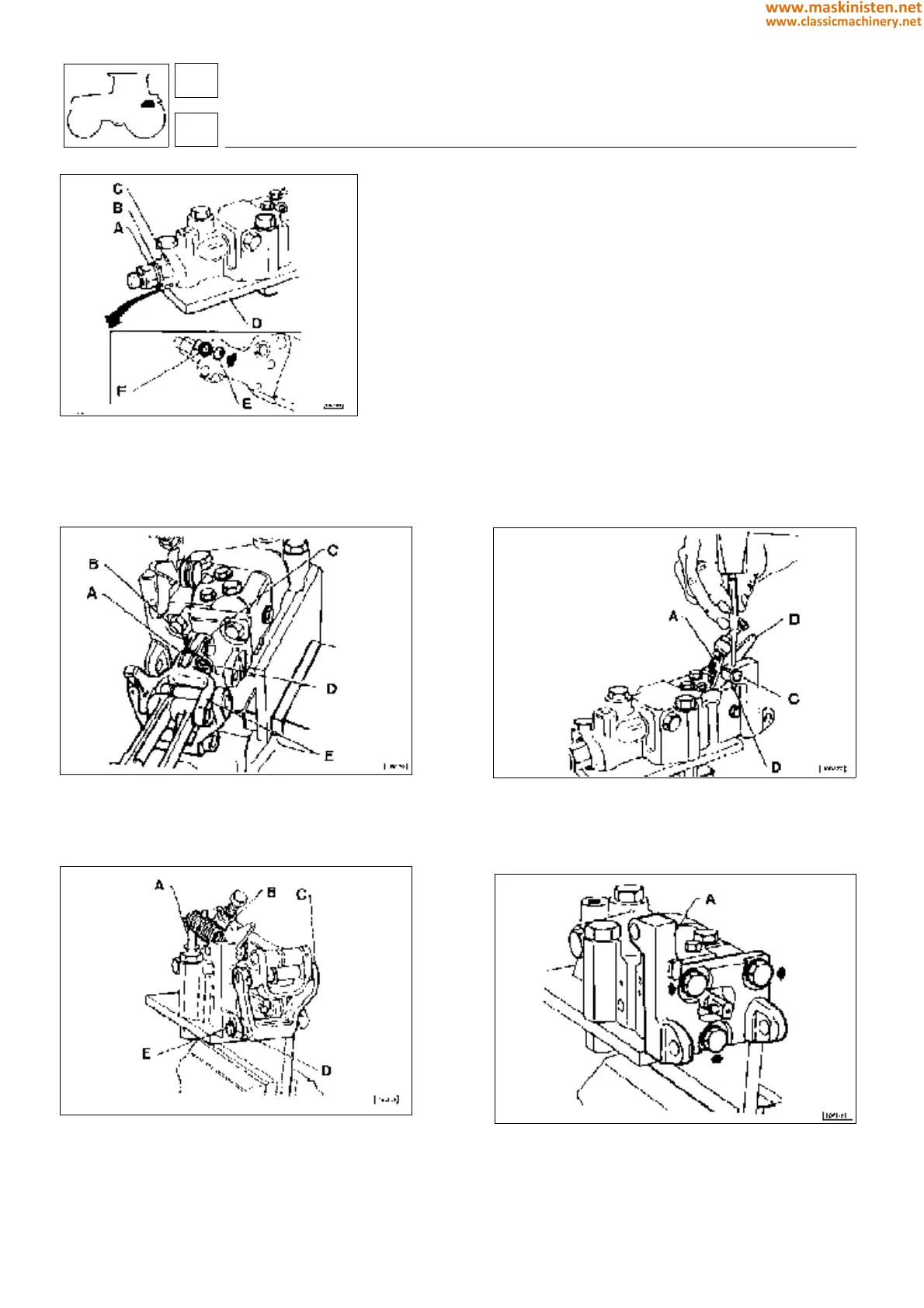

Fig. 17 - Hydraulic distributor seal ring.

A Anti-shock valve

B Gasket

C Fitting

D Plate

E Oil delivery hole to power-lift cylinder

F O-ring

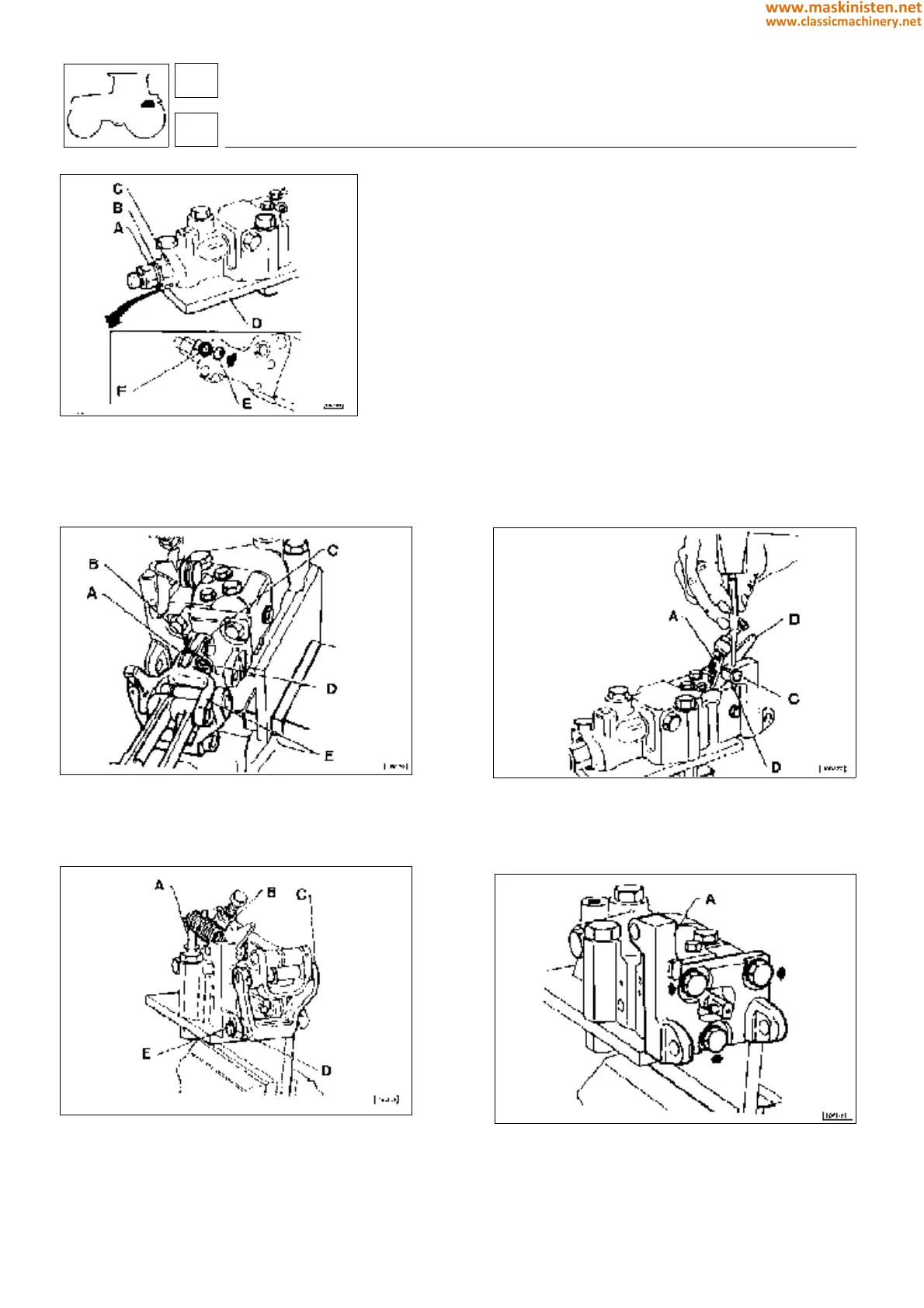

Fig. 18 - Hydraulic distributor control levers.

A Spacer

B Plate

C Distributor stem

D Pin

E Lever assembly

Fig. 19 - Removing the ratchet return spring.

A Spring securing pin

B Springs

C Fork

D Snap ring

E Pin

Checking distributor when assembled - Fig. 17

Before taking the distributor to pieces perform the nonreturn valve

tightness test operating as follows:

1. Fit O-ring F into hole E groove as shown in figure and then

secure plate D underneath the distributor using two bolts, so that

hole E be thoroughly sealed.

2. Loosen anti-shock valve A holding fitting C locked with a

spanner. Remove the valve along with underlying gasket B.

3. Connect hydraulic pump no. 5.9030.520.4 to fitting C; Press-

urize the oil through the pump and make sure no oil leaks from the

distributor.

4. Should any leaks be noticed, this could be caused by the poor

nonreturn valve efficiency. For this reason the hydraulic distributor

shall be completely overhauled.

Fig. 20 - Removing the distributor ratchet return spring.

A Spring

B Limit lever

C Pin

D Pin

Fig. 21 - Hydraulic distributor control mechanism support.

A Lever support

59

5

vehicle

rear hydraulic power-lift

274

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...