Filling the system with oil

Detach the low pressure hose from the recharge station and immerse the end in a graduated vessel containing 300 g

approx of SUNISO 5 GS or equivalent oil. Allow 250 grams of the oil to be drawn into the circuit.

Reconnect the hose to the station.

Filling the system with R134a refrigerant

When the low pressure gauge (2, Fig. 4) registers a minimum value (760 mm Hg) that remains stable for between 5

and 10 minutes, close the valve (E, Fig. 4).

Open the filler valve (5, Fig. 4) and wait until the specified quantity (1800 g) of refrigerant has entered the system.

In the event that the flow of refrigerant contained in the metering unit should be interrupted, warm the unit by means

of the electric heater (20, Fig. 4), rechecking the pressure on the relative gauge.

Should this not be sufficient, start the engine and throttle up to 1200 rev/min approx. Switch on the air conditioning

system, and the R 134a refrigerant will be drawn directly into the circuit by the compressor.

Close the filler valve (5, Fig. 4), and check with the leak detector that there is no escape of fluid from the fittings of the

circuit. Should any leaks be detected, these must be eliminated, and the refrigerant reintroduced.

Caution: In the event of oil leaks being detected, the circuit must be emptied completely and the entire recharge

procedure recommenced.

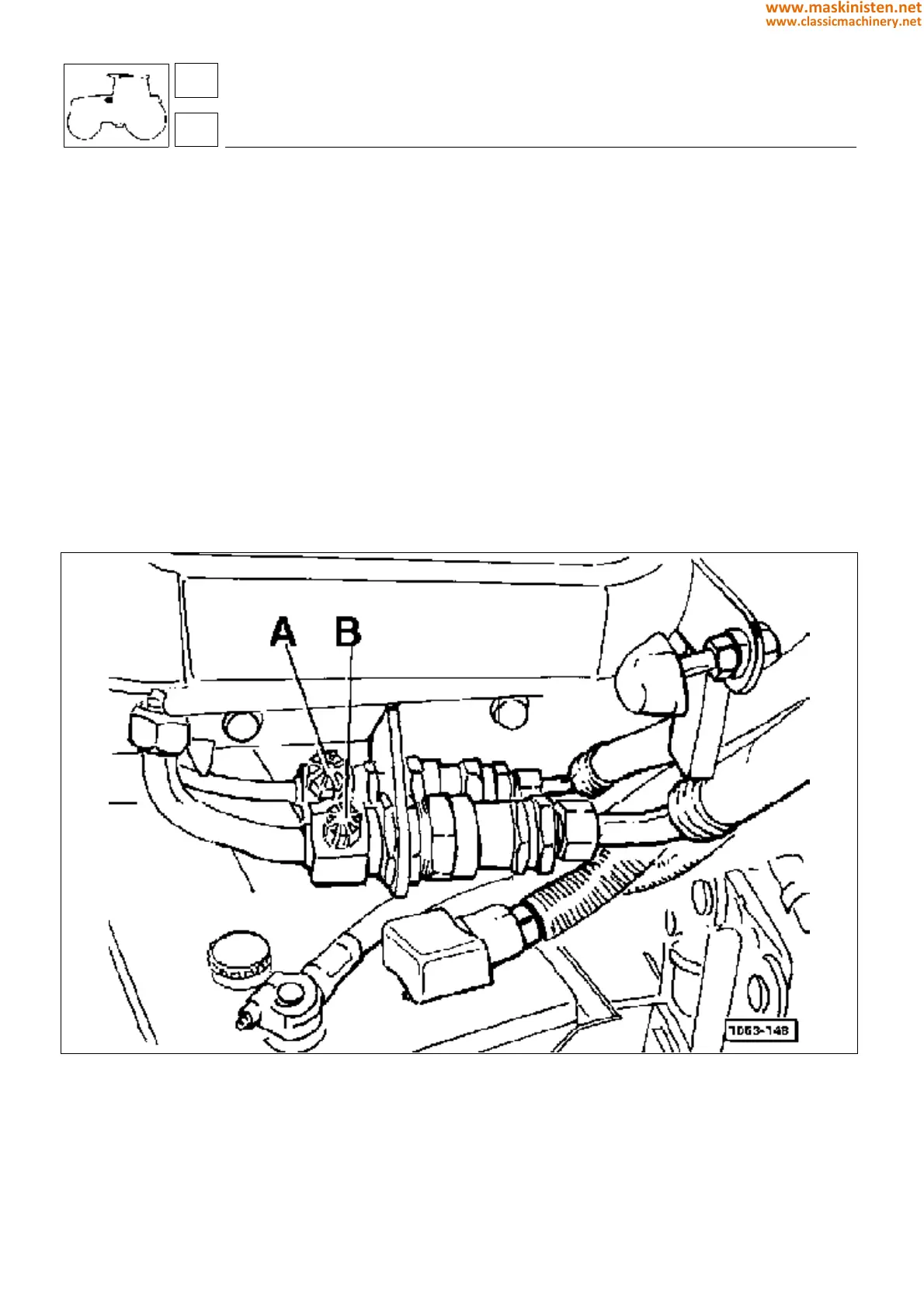

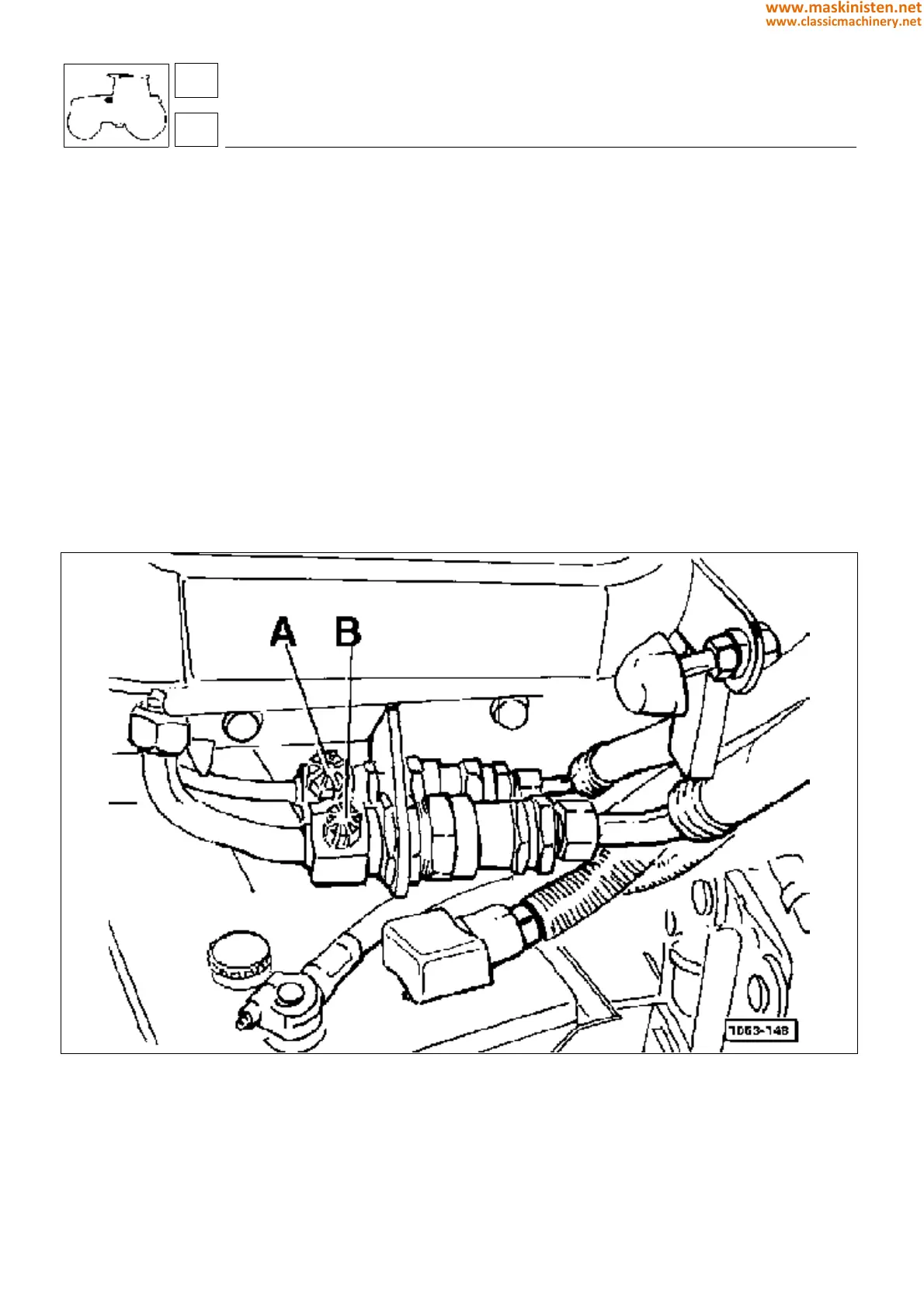

Fig. 4/a - Valves for connection of the tractor to the air conditioning recharge and service station.

A - "HIGH PRESSURE" valve

B - "LOW PRESSURE" valve

Final checks

Once all the refrigerant has been put into the air conditioning circuit, check (with the engine running and the system

in operation) that the high pressure gauge shows a value of between 15 and 20 bar, and the low pressure gauge a

value between 1.5 and 2.5 bar.

systems

air conditioning

86

8

370

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...