MX-2300/2700 N/G SIMULATION 7 – 92

50-2

Purpose : Adjustment

Function (Purpose) : Used to adjust the copy image position on

print paper in the copy mode and to adjust

the void area (image loss). (Simple adjust-

ment)

(Similar to SIM50-01. This simulation pro-

vides the simpler method.)

Section :–

Item : Image quality (Image position)

Operation/Procedure

1) In advance to this adjustment, execute the magnification ratio

adjustment in the sub scanning direction (SIM48-01).

2) Select "TRAY"and set 0 to L1 and L2.

* L1 and L2 are changed to 0, the following adjustment values

are automatically set.

RRCA adjustment value: 50

RRCB adjustment value: 90

(Reference value 50 + paper lead 49 (4.9mm))

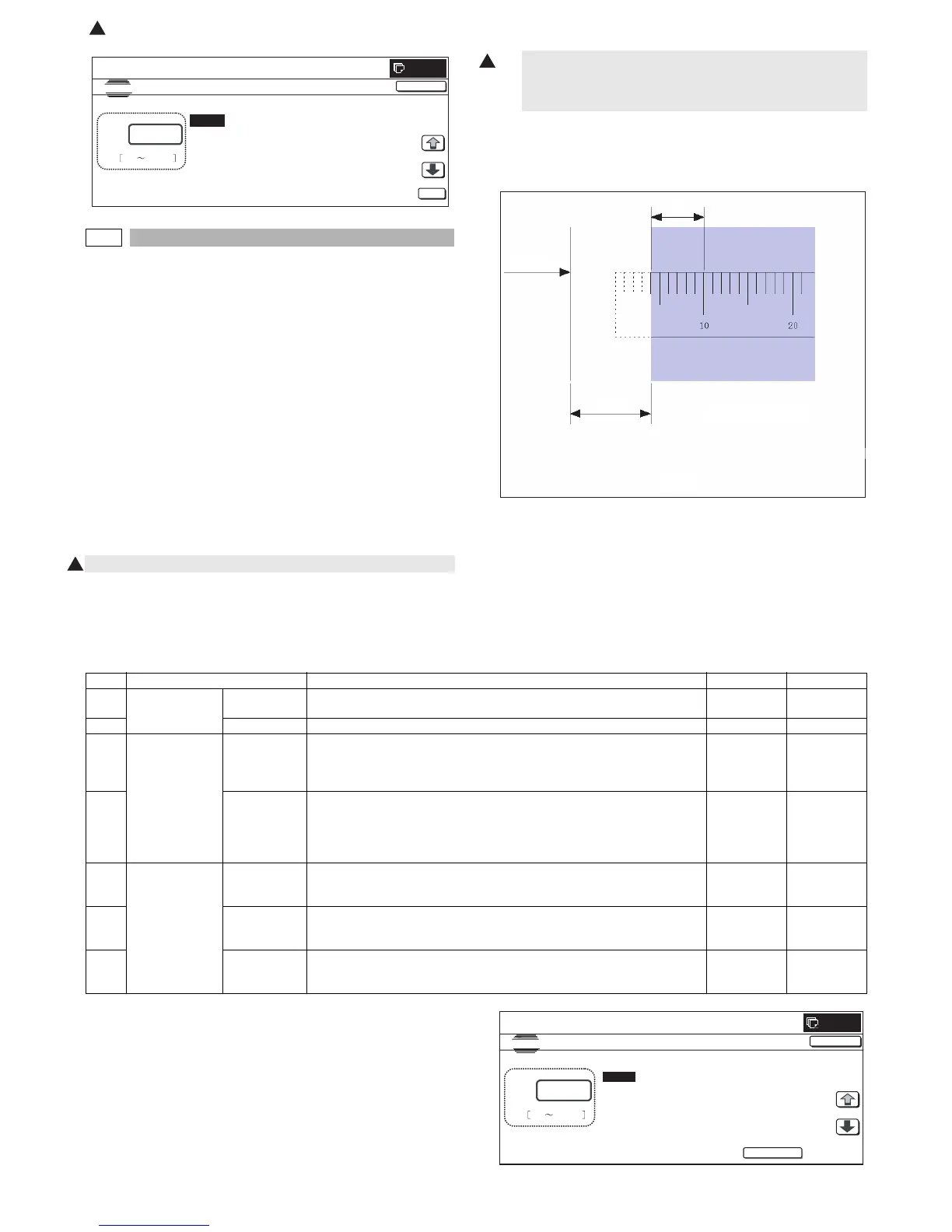

3) Place a ruler along the left edge of the document table, and

make a black copy in 400%.

4) Measure the distances L1 and L2 on the copied image in the

unit of 0.1mm, and multiple the distance values with 10, and

enter the obtained values. (Be sure to enter L1 and L2

together.)

• L1: Distance between the copy image lead edge position

and the scale of 10mm.

• L2: Distance between the paper lead edge and the copy

image lead edge position.

5) When [EXECUTE] button is pressed, the current entered value

is saved to EEPROM and RAM.

6) Make a black copy in 100%, and adjust the rear edge void.

* When [CLOSE] button is pressed, the display is shifted to the

copy basic screen of simulation.

* Copying can be performed also by pressing [COLOR]/[BLACK]

key.

<Set range and default value of each setup>

A to G:1step = 0.1mm

A. Document lead edge reference position: (L1), B. Paper lead

edge positions

Except for A and B, same as the item adjusted with SIM50-01.

The values adjusted with A and B are reflected to the document

lead edge reference position (RRC-A) and all the paper lead edge

positions (RRCB-**).

CLOSE

0

A:

A㧦 50

B㧦 50

C㧦 50

D㧦 50

㧧 RRCA

㧧 RRCB-CS12

㧧 RRCB-CS34

㧧 RRCB-LCC

SIMULA TION NO.50㧙01

LEAD EDGE ADJUSTMENT VALUE

50

0 99

OK

TEST

1

1

400% enlargement copy

Paper lead

edge

L1

L2

Fig. 1

Item Display item Description Set range Default value

A Actual measured

value

L1 Distance between the image lead edge and the scale of 10mm (Platen 400%,

unit of 0.1mm)

0 to 999 –

B L2 Distance between the paper lead edge and the image lead edge (unit of 0.1mm) 0 to 999 –

C Image loss

quantity set value

LEAD Lead edge image loss quantity setting

The lead edge image loss quantity is specified. Difference between the

document lead edge scan start position and the document lead edge

* The greater the value is, the greater the image loss is.

0 to 99 30

D SIDE Side image loss quantity setting

The side image loss (SIDE) is specified. (Document width – Document edge

scan range / 2

(The rear edge image loss quantity is fixed to 0. (Without adjustment))

* The greater the value is, the greater the image loss is.

0 to 99 20

E Void quantity

setting

DENA Print lead edge adjustment

The void quantity at the paper lead edge is specified.

* The greater the value is, the greater the void is.

1 to 99 30

F DENB Sub scanning direction print range adjustment

The void quantity at the paper rear edge is specified.

* The greater the value is, the greater the void is.

1 to 99 20

G FRONT/REAR FRONT/REAR void quantity adjustment

The void quantities at the left and right edges of paper are specified.

* The greater the value is, the greater the void is.

1 to 99 20

CLOSE

0

A:

A㧦 60

B㧦 0

C㧦 30

D㧦 15

㧧

L1

㧧

L2

㧧

LEAD

㧧

SIDE

SIMULATION NO.50-02

LEAD EDGE ADJUSTMENT VALUE(CALC)

60

0 999

TEST

EXECUTE

: Dec. 15 2005

1

Loading...

Loading...