Installation

FLOWSIC600-XT · Operating Instructions · 8018846/1BHP/V2-1/2021-05 · © SICK Engineering GmbH 53

Subject to change without notice

[1] The value increases by 1 DN when using meters with 2D / SD overall length.

[2] Class 0.5 is only achieved for the 8-path meter in this configuration.

NOTICE:

During operation, it is imperative to use the same flow conditioner as well

as the same pipes, in the same orientation as when calibrating the meter.

Mark the pipes and flow conditioner to indicate the flange alignment at the

time of calibration.

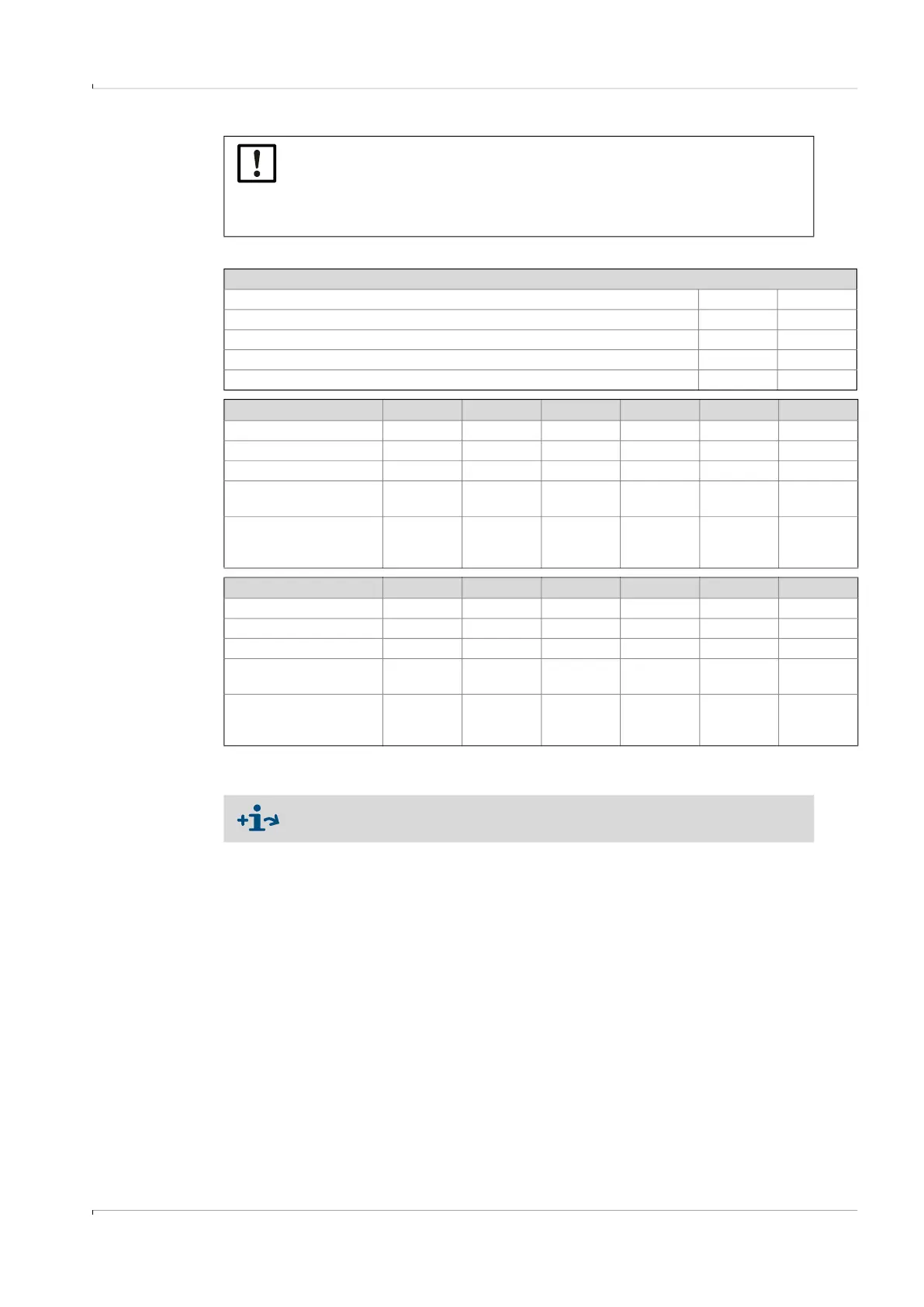

Configuration 1 (A)

OIML R137 A D

Class 1.0 7 DN 10 DN

Class 0.5 7 DN

2

10 DN

2

AGA Report 9 3rd Edition, July 2017 A D

“Metering package performance” according to Appendix C with CPA 50E 7 DN 10 DN

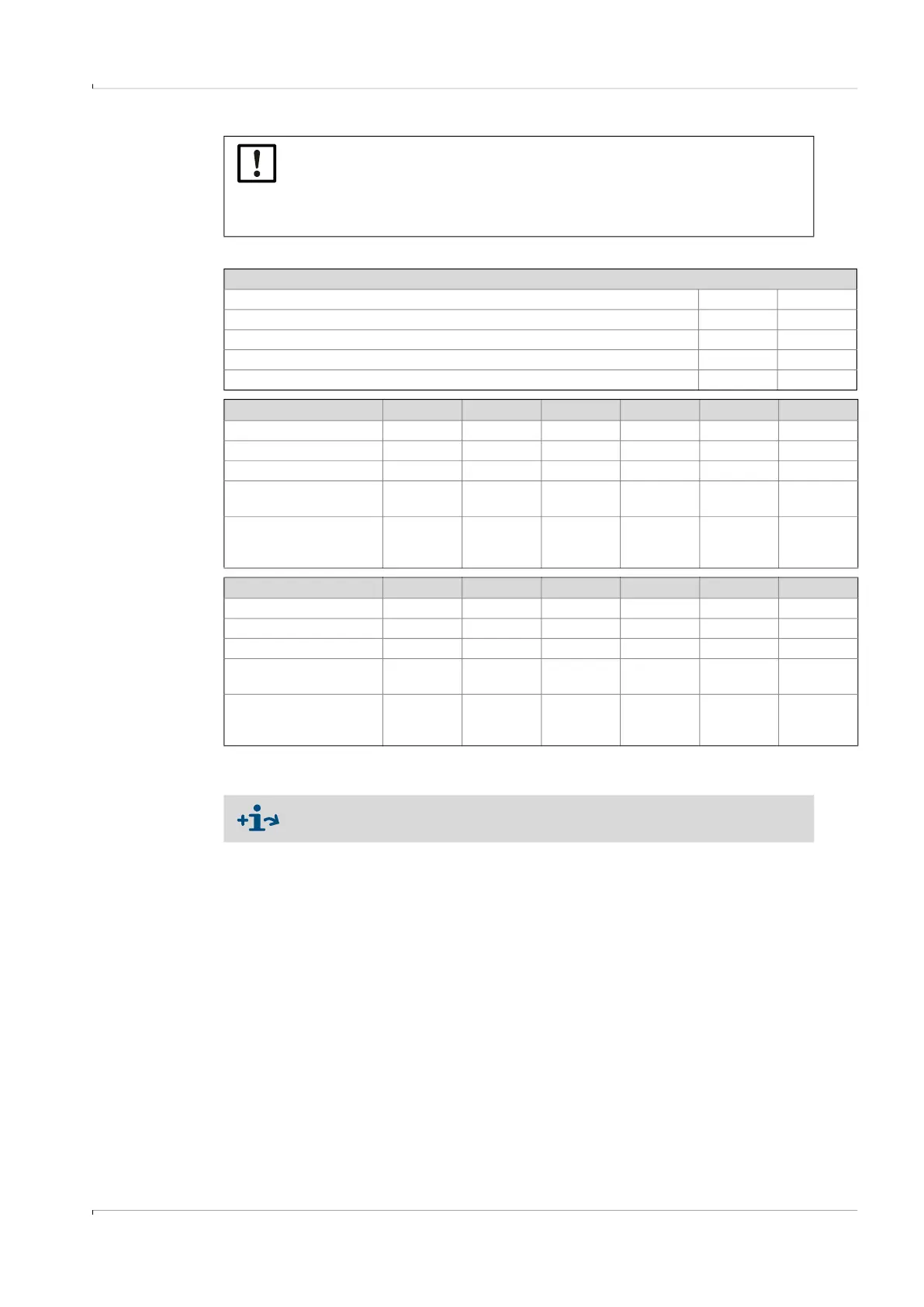

Configuration 2 (B1)

OIML R137 A B C D E F

Class 1.0 5 DN 2 DN 3 DN 5 DN 3 DN 2 DN

Class 0.5 7 DN 2 DN 5 DN 10 DN 8 DN 2 DN

AGA Report 9

3rd Edition, July 2017

A B C D E F

“Metering package perfor-

mance” according to

Appendix C with CPA 50E

10 DN 5 DN 5 DN 10 DN 5 DN 5 DN

Configuration 2 (B2)

OIML R137 A B C D E F

Class 1.0 6 DN 2 DN 4 DN 6 DN 4 DN 2 DN

Class 0.5 7 DN 2 DN 5 DN 10 DN 8 DN 2 DN

AGA Report 9

3rd Edition, July 2017

A B C D E F

“Metering package perfor-

mance” according to

Appendix C with CPA 50E

10 DN 5 DN 5 DN 10 DN 5 DN 5 DN

The maximum gas velocity in the pipe is limited to 40 m/s in configurations

with flow conditioner.

Loading...

Loading...