52 FLOWSIC600-XT · Operating Instructions · 8018846/1BHP/V2-1/2021-05 · © SICK Engineering GmbH

Installation

Subject to change without notice

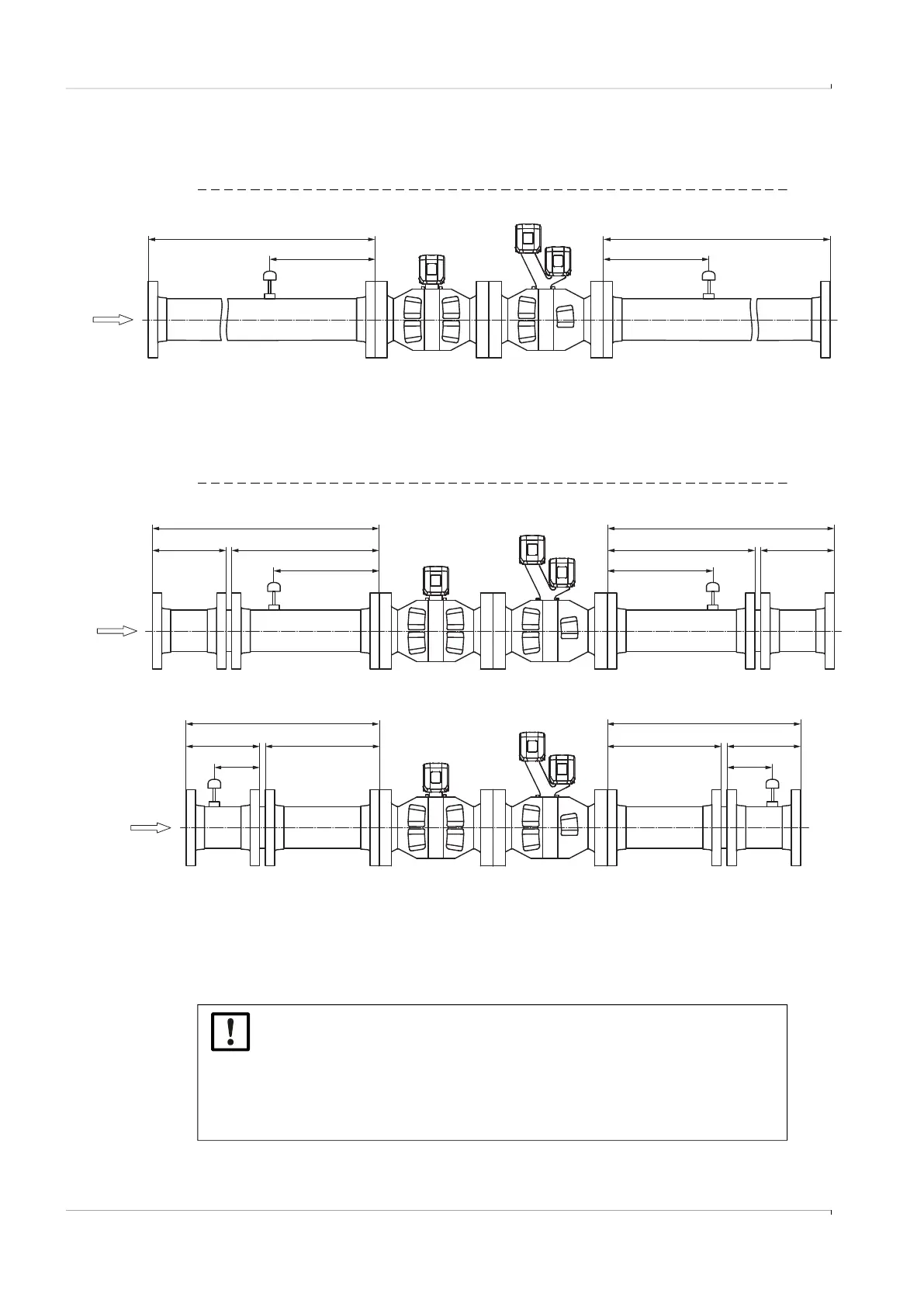

Flange-to-flange bidirectional

Fitting the FLOWSIC600-XT for bidirectional flange-to-flange use.

Fig. 23 Bidirectional flange-to-flange use without flow conditioner (configuration A)

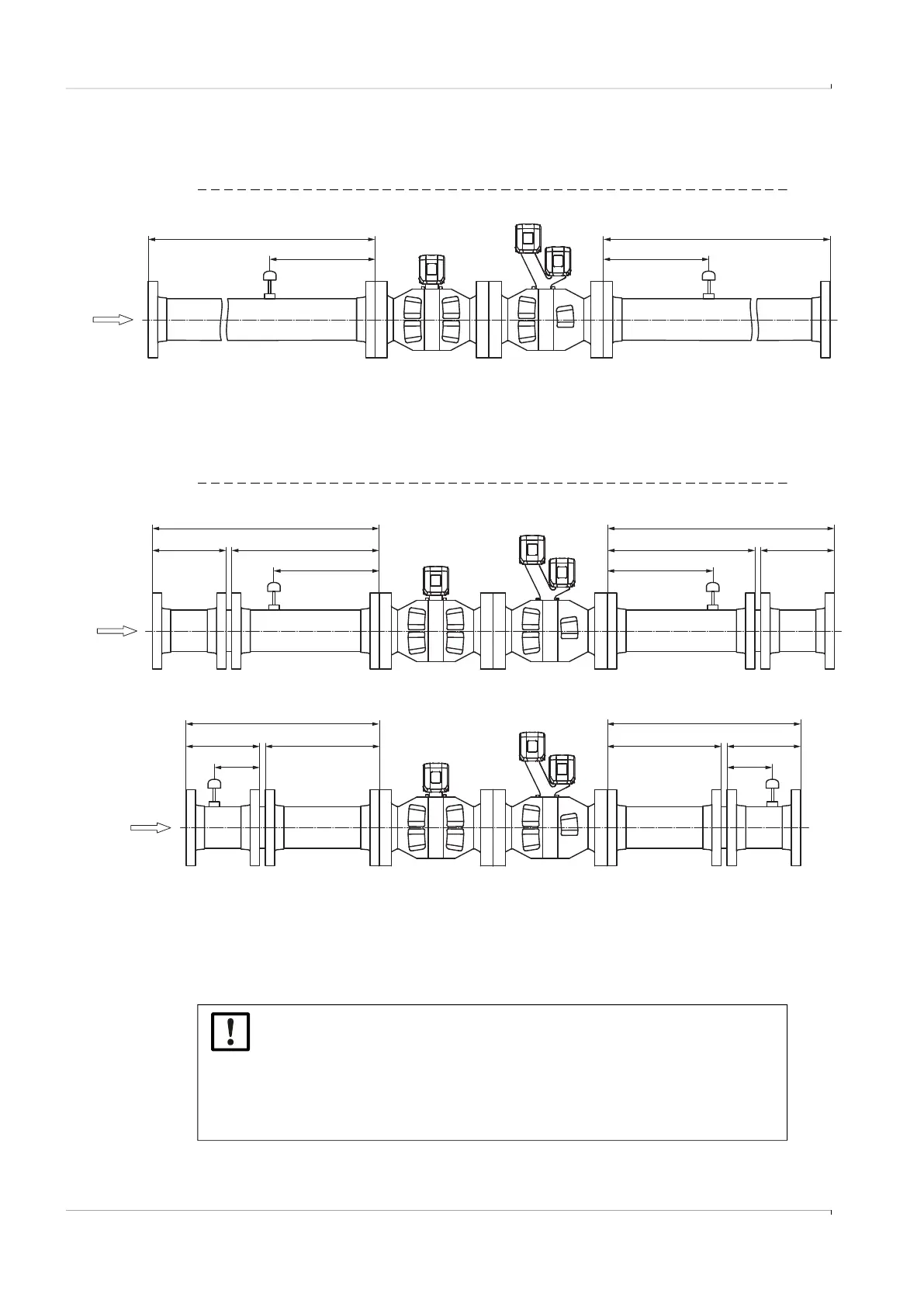

Fig. 24 Bidirectional flange-to-flange use with flow conditioner (configuration B)

A

3 ... 5 DN

≥ A

1

3

2

≥ D

3 ... 5 DN

3

1. FLOWSIC600-XT (8 paths)

2. FLOWSIC600-XT (4+1 paths)

3. Alternative temperature measuring points

NOTICE:

Installation configuration (B) with the flow conditioner refers exclusively to SICK

conditioner types (according to SICK documents 9211778 and 9211779).

When using conditioner types CPA 50E or 55E, a distance between the condi-

tioner and meter of at least 5DN inlet length must be considered. When other

conditioners are used, the installation configuration can be different and must

be agreed with SICK.

3 ... 5 DN

≥ C≥ B

1

3

4

B1

2

1 DN

≥ C≥ B

1

3

4

B2

2

4

4

3

3

≥ E ≥ F

3 ... 5 DN

≥ F≥ E

1 DN

≥ A

≥ D

≥ A

≥ D

1. FLOWSIC600-XT (8 paths)

2. FLOWSIC600-XT (4+1 paths)

3. Alternative temperature measuring points

4. SICK flow conditioner

Loading...

Loading...